In today's electronics industry, preventing overheating is paramount to ensuring the reliability and performance of electronic devices. Cooling heat sinks play a crucial role in this process, acting as passive cooling solutions that dissipate heat generated by electronic components. Understanding the importance of cooling heat sinks and selecting the best heat sink manufacturer for your needs is essential for maintaining optimal operating temperatures and preventing overheating-related issues.

Thermal management is a significant concern in electronics design, as excessive heat can lead to reduced lifespan, performance degradation, and even system failure. Electronic components such as CPUs, GPUs, power transistors, and integrated circuits generate heat during operation, which must be effectively dissipated to prevent overheating. Cooling heat sinks provide an efficient solution to this problem by absorbing heat from these components and transferring it away through conduction, convection, and radiation.

The design and construction of cooling heat sinks are critical factors in their effectiveness. The best heat sink manufacturer specializes in creating custom thermal solutions tailored to the specific requirements of various electronic applications. By utilizing advanced materials, engineering techniques, and thermal analysis tools, they can optimize the design of heat sinks to maximize heat dissipation and thermal performance.

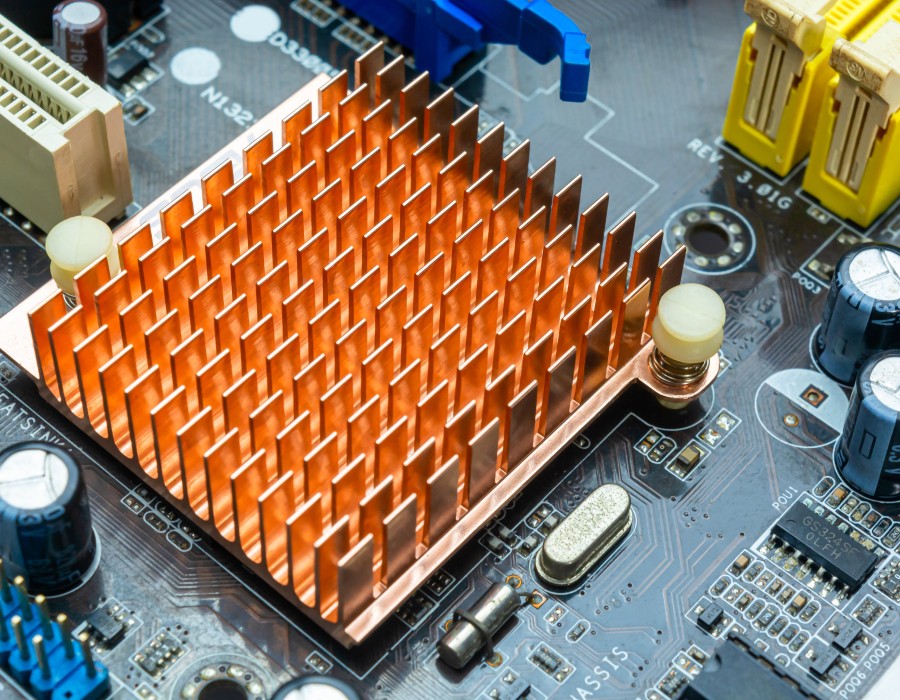

Cooling heat sinks typically consist of a base plate and fins, which increase the surface area available for heat transfer. The base plate is in direct contact with the electronic component, while the fins extend outward to increase contact with the surrounding air. As heat transfers from the component to the base plate, it spreads through the fins, where it is then dissipated into the surrounding environment.

Several factors influence the effectiveness of cooling heat sinks, including the materials used, fin design, airflow, and mounting method. Aluminum and copper are commonly used materials due to their high thermal conductivity, lightweight, and cost-effectiveness. The design of the fins, such as their size, shape, spacing, and surface area, also plays a crucial role in optimizing heat transfer.

Airflow is another critical factor in cooling heat sink performance. Adequate airflow is necessary to carry heat away from the heat sink and prevent the buildup of hot air around the electronic components. Proper ventilation and placement of heat sinks within the electronic device are essential to ensure sufficient airflow and maximize cooling efficiency.

Selecting the best heat sink manufacturer is essential for ensuring the reliability and performance of cooling heat sinks. By partnering with a reputable and experienced manufacturer, electronics manufacturers can access expertise, resources, and support throughout the product development lifecycle. From initial design consultation to prototyping, testing, and production, the best heat sink manufacturer collaborates closely with their clients to deliver customized thermal solutions that meet their specific requirements and constraints.

Cooling heat sinks play a vital role in preventing electronics overheating and maintaining optimal operating temperatures. By partnering with the best heat sink manufacturer and utilizing custom thermal solutions, electronics manufacturers can ensure the reliability, performance, and longevity of their products in today's demanding electronics industry.

Comments