Electric arc incidents remain one of the most severe hazards faced by electrical workers worldwide. An arc flash can reach temperatures exceeding 19,000°C (35,000°F) — hotter than the surface of the sun — and can release massive energy in milliseconds. The result is intense thermal radiation, molten metal ejection, and explosive pressure waves capable of causing fatal injuries.

To safeguard against such extreme conditions, arc-rated protective clothing (AR or FR PPE) is engineered with flame-resistant fabrics and tested under strict international standards such as ASTM F1506, IEC 61482-2, and NFPA 70E. While much attention is given to the fabric’s Arc Thermal Performance Value (ATPV) or Energy Breakopen Threshold (EBT), the constructional elements of the garment — specifically seam design and fasteners — play a crucial yet often underestimated role in the overall arc resistance of protective apparel.

Understanding the Mechanism of Arc Flash Exposure

Before delving into garment construction, it’s vital to understand what happens during an arc event:

- Thermal Energy – High-intensity heat vaporizes nearby metal and causes severe burns on contact.

- Convective Heat and Plasma Jet – Expanding plasma transfers energy through air, causing fabric ignition or charring.

- Pressure Shockwave – Rapid expansion generates blast forces that can tear garments apart.

- Molten Metal Spatter – Ejected particles can embed in seams or openings, leading to localized failures.

Protective clothing must therefore not only resist ignition but also maintain structural integrity under this intense, transient load. Seams and fasteners, as the weakest mechanical points in any garment, become critical in preventing breakopen or flame ingress.

Role of Seam Design in Arc Resistance

Seams are more than stitching lines — they are stress concentrators and potential thermal weak zones. The configuration, thread type, and stitch density directly affect how a garment performs under arc exposure.

1. Seam Types and Their Performance

Common seam types in arc-rated clothing include:

- Safety Stitch (Double Stitch or Overlock): Offers high mechanical strength and redundancy; often used in outerwear and coveralls.

- Flat-Felled Seam: Two layers of fabric folded and stitched, providing a smooth finish and enhanced tensile strength; commonly used in high-stress areas like shoulders and sleeves.

- Lapped Seam: Simpler and lighter but less resistant to tearing under pressure or heat.

- Bound Seam: Edges enclosed with tape; useful for minimizing fraying and molten metal accumulation.

According to studies from DuPont™ and ArcWear, flat-felled and double-stitched seams demonstrate superior arc containment and reduced breakopen probability compared to single-stitched or lapped seams. The extra fabric overlap acts as an additional insulation layer, while multiple stitch rows distribute stress more uniformly during an explosion.

2. Stitch Density and Thread Tension

An overly tight stitch can weaken the seam because excessive tension cuts into the fabric, reducing flexibility and promoting tear initiation. Conversely, loose stitches reduce structural integrity.

Optimal stitch density for arc-rated garments generally falls between 8–10 stitches per inch (SPI) for medium-weight fabrics, balancing strength and elasticity. Manufacturers conduct seam burst and tensile strength tests (ASTM D1683) to verify that seam performance equals or exceeds the base fabric’s mechanical strength.

3. Thread Type and Thermal Stability

Threads must retain strength under extreme heat; otherwise, the seam will open even if the fabric remains intact.

Preferred thread materials include:

- Meta-aramid (Nomex®): High heat resistance up to ~370°C continuous; does not melt or drip.

- Para-aramid (Kevlar®): Superior tensile strength, used where high mechanical stress is expected.

- PTFE-Coated Aramid Threads: Offer chemical and UV resistance, maintaining performance over longer service life.

Threads made of polyester or nylon are strictly avoided in primary arc protective layers as they melt at 250°C–260°C, leading to seam failure and secondary skin injury.

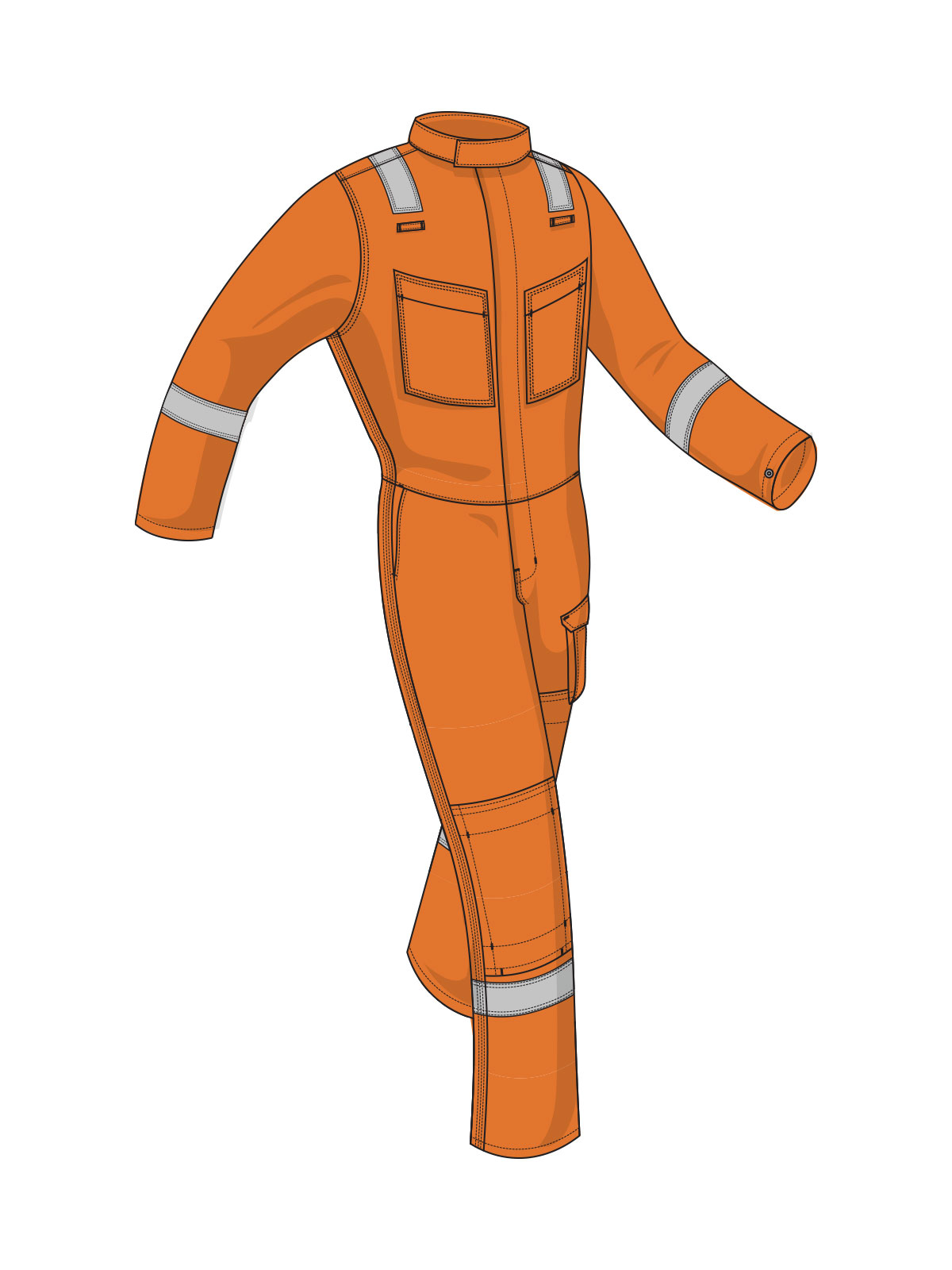

4. Seam Placement and Garment Ergonomics

Seam positioning also affects protection. Placing seams away from high-exposure zones — such as front torso, arms, and legs — minimizes direct energy impact. Designers strategically relocate seams toward lower-risk zones or reinforce them with protective flaps and layered stitching.

Ergonomic considerations also matter. Seam bulges can create localized thermal bridges, allowing higher heat conduction. Modern designs use flat or offset seams to reduce heat concentration and improve mobility.

Fasteners: The Often-Overlooked Weak Link

Fasteners — zippers, snaps, buttons, hook-and-loop systems, or closures — are essential for function and fit, but they also present significant risks during arc events. Their material compositionand positioning can determine whether a garment maintains integrity or fails catastrophically.

1. Zippers

Metal zippers, if exposed, conduct heat and electricity, posing burn and shock hazards. Therefore, non-metallic, high-temperature-resistant zippers are preferred.

- Nomex®-taped zippers with brass or aluminum teeth covered by protective flaps are commonly used.

- Coil zippers made from aramid or thermoplastic with FR coatings maintain flexibility without significant conductivity.

The IEC 61482-2:2018 standard explicitly recommends covering all metal components with flame-resistant fabric closures or storm flaps.

Additionally, zipper tapes must be made from FR-rated materials to avoid melting under radiant heat. Testing per ASTM F1930 (Manikin Test) often reveals that unprotected zippers become failure initiation points if exposed directly to arc energy.

2. Snaps and Buttons

Metal snaps and buttons are strong but highly conductive. If not properly insulated, they can heat up rapidly, causing contact burns even without direct flame.

To mitigate this:

- Hidden snaps under fabric layers are standard practice.

- Plastic FR-rated fasteners (e.g., PEEK or melamine-based) are used in low-heat zones like pockets.

- Some manufacturers employ dielectric coatings on metallic snaps to reduce conductivity.

The NFPA 70E guidelines emphasize the need to shield conductive components from skin contact, especially in clothing for Category 2 and above arc flash protection.

3. Hook-and-Loop (Velcro) Systems

Hook-and-loop closures are convenient for cuffs, collars, and pocket flaps. However, not all are arc-rated. Conventional nylon-based Velcro melts quickly. Only FR-treated aramid or oxidized PAN hook-and-loop materials maintain adhesion under arc exposure.

Manufacturers test these closures under ASTM F1959/F1959M (determining ATPV/EBT) to confirm that the closure does not ignite, melt, or separate during an event.

4. Thread and Binding on Fasteners

Even when fasteners themselves are arc-rated, failure can occur if non-FR sewing threads ortapes are used in their attachment. Consistency across all garment components is critical — a fully arc-rated system requires every component, including trims, threads, and labels, to meet the required arc protection category.

Impact on Arc Resistance and Test Results

Arc resistance of a garment is a system property, not just a fabric attribute. A garment constructed from high-ATPV fabric may still fail if seams or fasteners open prematurely.

Empirical findings from multiple laboratory evaluations (ArcWear, Kinectrics, and DuPont Technical Reports) have shown:

- Garments with reinforced double-stitched seams demonstrated 20–30% higher energy absorption before breakopen compared to single-seamed counterparts.

- Poor seam construction often caused localized charring and rupture even when fabric performance remained intact.

- Exposed metal zippers and snaps frequently recorded surface temperatures above 200°C post-test, capable of causing second-degree burns upon contact.

- Protective flaps over fasteners reduced heat transfer by up to 70%, depending on fabric thickness and spacing.

Such data underscore the principle that garment design integrity is as critical as material selection.

Testing Standards and Compliance

Several international standards govern testing of seams and fasteners for arc flash PPE:

Standard

Scope

ASTM F1506

Specifies performance and labeling requirements for arc-rated clothing; includes seam and closure design criteria.

IEC 61482-2

Evaluates protective clothing for electric arc exposure; mandates closure protection and component consistency.

ASTM D6413

Tests vertical flame resistance of fabrics, threads, and components.

ISO 17493

Determines thermal stability at elevated temperatures for non-metallic materials.

ASTM F1959/F1959M

Measures arc rating (ATPV/EBT) of fabric assemblies, including seams and closures.

Manufacturers must ensure full garment-level certification, not merely fabric testing, as field failures often originate at seams or closures that were not tested as part of the system.

Innovations in Seam and Fastener Technology

Modern PPE manufacturers are investing in integrated protective construction that enhances both comfort and safety:

- Laser-Welded Seams: Eliminate stitching altogether, reducing thread degradation and providing uniform strength.

- Ultrasonic Bonding: Creates sealed joins without puncturing fabric, minimizing molten metal ingress.

- Smart Fasteners: FR-rated polymers with embedded RFID chips for garment tracking and maintenance logs.

- Hybrid Closures: Combination of hidden zippers with overlapping Velcro flaps to ensure redundancy.

- Seamless Knitted Zones: Applied in base layers to eliminate pressure points and enhance mobility.

Such innovations represent the next frontier of ergonomic and high-performance arc protection design.

Maintenance and Inspection Considerations

Even the most advanced garment can lose protection if seams or fasteners degrade over time. Periodic inspection should include:

- Checking for loose stitching, discoloration, or fabric separation.

- Ensuring zipper teeth alignment and fastener adhesion after washing cycles.

- Avoiding repairs using non-FR threads or tapes.

- Replacing garments showing melted or brittle fasteners.

Washing should comply with ISO 6330 or manufacturer guidelines, avoiding harsh chemicals that compromise FR coatings.

In electric arc protective clothing, fabric quality defines resistance, but seam design and fasteners determine survival. These components transform individual materials into a coherent safety system — one that must endure explosive heat, pressure, and radiation simultaneously.

An arc-rated garment is only as strong as its weakest joint. Poor seam engineering or unprotected fasteners can turn a compliant suit into a failure point under arc stress. Therefore, manufacturers must treat stitch design, thread composition, and closure integration with the same precision given to fabric selection and testing.

Future innovations — from laser bonding to FR-smart fasteners — continue to advance this field, bridging safety with comfort. Ultimately, optimizing seam and fastener design is not merely about meeting standards; it is about preserving lives when milliseconds matter most.

Comments