The brake master cylinder is an essential component of any vehicle's braking system, acting as the heart that ensures the safe and efficient operation of the brakes. While often overlooked, the master cylinder plays a critical role in converting the pressure applied to the brake pedal into hydraulic force, enabling the stopping power that keeps us safe on the road. In this article, we will delve into the workings of the brake master cylinder, its importance, and how it contributes to your vehicle's overall braking performance.

Function and Operation:

The brake master cylinder is a hydraulic pump that generates the hydraulic pressure necessary to activate the brakes. When you press the brake pedal, it pushes a piston within the master cylinder, which in turn forces brake fluid into the brake lines. This pressurized fluid is then transmitted to the individual brake calipers or wheel cylinders, causing the brake pads or shoes to engage with the rotors or drums, thus slowing down or stopping the vehicle.

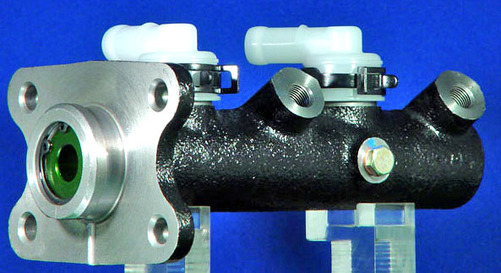

The master cylinder consists of a reservoir, a piston, and a series of valves. The reservoir holds an adequate amount of brake fluid, ensuring a constant supply is available for the system. The piston is connected to the brake pedal and moves in response to the pressure applied. As the piston moves forward, it pressurizes the brake fluid, which is then distributed to the brakes through the interconnected brake lines. The valves within the master cylinder regulate the flow of brake fluid and help maintain balance and equal pressure between the brakes.

Types of Master Cylinders:

There are two main types of brake master cylinders: the single-circuit master cylinder and the dual-circuit master cylinder. The single-circuit master cylinder is commonly found in older vehicles and operates all the brakes from a single hydraulic circuit. If a failure occurs, such as a leak or a loss of pressure, the entire braking system may be compromised, resulting in a complete loss of brakes.

On the other hand, the dual-circuit master cylinder, which is prevalent in modern vehicles, has two separate hydraulic circuits. Each circuit is responsible for supplying brake pressure to either the front or rear wheels. This design provides an added level of safety, as if one circuit fails, the other can still provide partial braking ability, allowing the driver to maintain control and stop the vehicle safely.

Maintenance and Troubleshooting:

Proper maintenance of the brake master cylinder is vital for the overall performance and safety of your vehicle's braking system. Regularly checking the brake fluid level and ensuring it is clean and free from contaminants is crucial. If the fluid appears discolored or contains particles, it may be a sign of internal component wear or a leak, necessitating further inspection and possible repairs.

Furthermore, if you notice a spongy or soft brake pedal, a loss of braking power, or any signs of fluid leakage around the master cylinder, it is essential to have the system inspected by a qualified mechanic. These symptoms could indicate a failing master cylinder, worn seals, or other issues that require attention. Ignoring such warning signs may compromise your ability to stop your vehicle effectively, posing a serious safety risk.

The brake master cylinder is a fundamental component of the braking system that ensures your vehicle's ability to stop safely. Understanding its function and the importance of regular maintenance is crucial for every driver. By staying attentive to the signs of wear and promptly addressing any issues, you can ensure that your brake master cylinder performs optimally, providing you with reliable and responsive braking power when you need it most. Remember, maintaining your brakes is not just about convenience; it's about safeguarding yourself and others on the road.

For More Info:-

Comments