Ever curious about how a T-shirt gets from the cotton field to your closet AND still allows for profit margins? Enter the Value Chain Analysis. It can be likened to your VIP pass to all the steps involved in creating, marketing and delivering a product.

Here, in this article, I’ll be imparting hands on insights, expert advice and practical examples that demonstrate how companies transform raw materials into revenue.

What Is Value Chain Analysis?

Value Chain Analysis was first outlined by Michael Porter in 1985. The value chain divides an organization into its strategic value creating activities in a way that the creation of value and profit can be observed. Put simply, all the activities ranging from the purchase of raw materials to after sales service, are grouped into primary and support activities. After consideration of the cost and choices at each link, companies can ascertain where they can reduce waste, enhance quality and obtain a competitive advantage.

“Competitive advantage grows fundamentally out of the value a firm can create.”

— Michael E. Porter, Competitive Advantage (1985)

Mapping the Journey: The Five Primary Activities

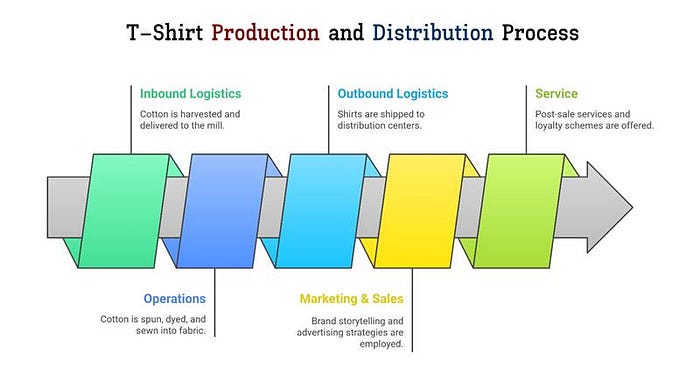

Let’s walk through the classic five stages, using my favorite example: your everyday T-shirt.

- Inbound Logistics: That’s how cotton shows up at your door. Farmers harvest, bale and deliver raw materials to the mill. I once visited a textile warehouse in Gujarat, India and witnessed firsthand how staggered deliveries keep factories churning without expensive storage overruns.

- Operations: These yarns are produced by spinning the cotton, are colored by dyeing, and are sewn into fabric. Garment factories cut and sew sections together subsequently. Each machine cycle, each working hour, adds cost. By streamlining schedules and reducing defects, companies reduce costs by up to 15%.

- Outbound Logistics: Completed shirts are boxed, palletized, and shipped by truck or airlifted to distribution centers around the globe. Amazon one day shipping guarantee has much to do with smoothly linked outbound systems. It isn’t magic rather, it’s precise route planning and real-time stock monitoring.

- Marketing & Sales: That’s where your brand conveys its storytelling. Does your T-shirt have “100% organic cotton,” “limited edition,” or “certified by a star”? These are phrases that generate perceived value. I remember working with a tiny fashion start-up to refine its messages: a tweak in ad copy emphasizing “handcrafted in India” raised online conversions by 20%.

- Service: Post sale, fast after sales service, effortless returns, and loyalty schemes continue to inspire repeat purchases. For instance, Zappos made its name through free two-way shipping, converting a 10% return ratio into a marketing triumph and a 75% repeat purchase ratio.

Zoom image will be displayed

The Supporting Cast: Infrastructure, HR, Technology, Procurement

Behind every primary activity stand the support process:

- Firm Infrastructure: Finance, legal, and administrative systems that keep the machinery going.

- Human Resource Management: Hiring skilled textile workers, training customer service reps, and keeping morale high.

- Technology Development: From looms that are automated to AI based demand forecasting.

- Procurement: Dealing with software vendors or cotton farmers to obtain the best possible deal.

Why It Matters: From Cost Cutting to Differentiation

Value Chain Analysis isn’t exclusive to large companies it can be applied by startups and non profits as well:

- Cost Leadership: Cut and eliminate bottlenecks. I’ve witnessed a bakery reduce and eliminate flour expenses by ordering from a local mill, reducing $5,000 in monthly expenses.

- Differentiation: Determine ways in which you can provide exclusive attributes like green packaging or special engravings that buyers will be willing to pay for.

- Strategic Focus: Consider outsourcing the low-value steps (e.g., shipping) and focusing investments on the high value steps (e.g., design or after-sales service).

By zooming in on each link, you decide where to compete harder, where to partner, and where to innovate.

Bringing It to Life: A Mini Example

Brand X, a boutique sneaker label, used value chain analysis to transform its business. After mapping every step, they discovered their highest margins came not from manufacturing but from limited edition collaborations and viral marketing. By outsourcing shoe assembly to a reliable contractor and reinvesting savings into influencer campaigns, they doubled profits in nine months.

Conclusion

By dissecting every link starting with inbound logistics and operations through the sale and service Value Chain Analysis sheds light on precisely where value is being created, costs can be cut, and differentiators are found. Whether your operation is that of a lone craftsman tracing material source or multinational brand tightening distribution, this template makes complexity obvious.

With clear sight of primary and support activities, data-driven decisions are yours to make: outsource what robs resources, invest where margins are strong, and create differentiation that comes to the attention of your customers. Begin your own value chain exercise now and turn every phase into a source of profit and long-term competitive advantage.

If you’re a PhD researcher looking to elevate the quality and impact of your work, we’re here to support you at every stage of your academic journey. Whether you need expert guidance on crafting a compelling research proposal, selecting the right methodology, or navigating complex data analysis, our team of research professionals is ready to help.

Connect with us today to take the next confident step in your research journey.

Frequently Asked Questions

1. What’s the core purpose of value chain analysis?

It identifies where the business builds or loses value, assisting in the making of cost-cutting and product differentiation decisions.

2. How detailed should my analysis be?

As granular as possible: segment activities at the sub activity level (e.g., distinguish dyeing from weaving) to determine focal points of potential improvement.

3. Can small businesses benefit?

Definitely. Even a lone craftsman can lay out material sourcing, manufacturing, and selling in order to maximize time and costs.

4. How often should it be revisited?

Value chains evolve with technology, costs, and customer tastes — review at least annually or when launching new products.

5. Any tools or templates to get started?

Yes Porter’s original model, in addition to numerous free online maps and software (e.g., Lucidchart, Miro) make mapping a breeze.

Comments