A stainless-steel plate factory is a manufacturing facility specializing in producing stainless-steel plates. These factories play a crucial role in the supply chain of stainless-steel products, catering to various industries such as construction, automotive, aerospace, food processing, and more. Stainless steel plates are widely used due to their exceptional strength, corrosion resistance, and aesthetic appeal.

Raw Material Selection

Stainless Steel Plate Factory carefully choose high-quality stainless-steel coils or sheets as their raw materials. These materials are selected based on their chemical composition, mechanical properties, and surface finish requirements.

Cutting and Slitting

The raw stainless-steel coils are first cut into appropriate sizes to match the required dimensions of the plates. It can be done using various cutting methods such as shearing, plasma cutting, or laser cutting. Slitting machines are then used to divide the coils into narrower strips further if needed.

Forming and Rolling

The cut stainless steel strips are fed into rolling mills or press brakes, where they undergo a series of forming processes. These processes include hot rolling, cold rolling, and heat treatment, which help shape the strips into flat plates with the desired thickness and surface characteristics.

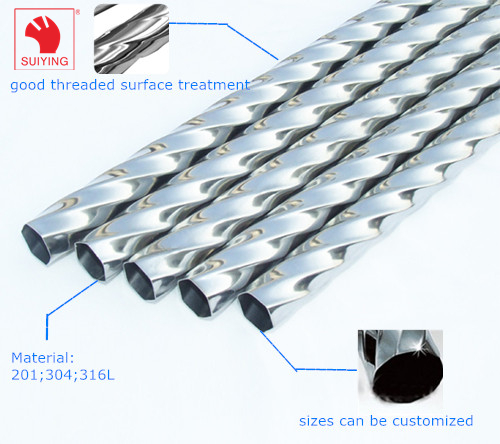

Surface Treatment

Stainless steel plates often undergo surface treatment processes to enhance their appearance and performance. These treatments may include pickling, passivation, grinding, or polishing, depending on the desired finish and application requirements.

Quality Inspection

Strict quality control measures are implemented throughout the production process to ensure that the stainless-steel plates meet the required standards. It involves dimensional checks, visual inspections, and various tests such as hardness testing, corrosion resistance testing, and mechanical property testing.

Packaging and Shipping

Once the stainless-steel plates pass the quality inspection, Stainless Steel Pipe Wholesaler are carefully packaged to protect them from damage during transportation. The plates are usually packed in wooden crates, pallets, or protective films. They are then ready for shipment to customers or stockists.

Material Traceability

China Stainless Pipe Manufacturer maintains a robust system for material traceability, ensuring that the origin and quality of the raw materials can be accurately traced throughout the production process. It helps in maintaining consistent quality and addressing any issues that may arise.

In-Process Inspections

Quality control personnel perform regular inspections at various stages of the production process. It includes checking the plates' dimensions, surface finish, and physical properties to ensure they meet the required specifications.

Testing and Certification

Stainless steel plate factories conduct a range of tests on the finished plates to verify their quality. These tests may include tensile testing, impact testing, ultrasonic testing, and corrosion resistance testing.

Continuous Improvement

Stainless steel plate factories strive for continuous improvement by analyzing production data, customer feedback, and market trends. It enables them to identify areas for development implement measures to enhance their processes and products.

FAQs

Is stainless steel plate safe?

Yes, stainless steel plates are generally considered safe for everyday uses. Stainless steel is a popular material for various applications.

Which stainless steel pipe is best?

Austenitic stainless steel pipes (e.g., 304, 316) are the best choice for their excellent corrosion resistance and versatility.

Comments