Electric coils are the unsung heroes of modern technology, playing a pivotal role in numerous applications across various industries. Behind these indispensable components are electric coil manufacturers who engineer and produce these intricate devices. In this article, we will delve into the world of electric coil manufacturers, exploring their significance, the diverse applications of electric coils, the manufacturing process, and how they contribute to technological advancements that shape our daily lives.

The Significance of Electric Coils

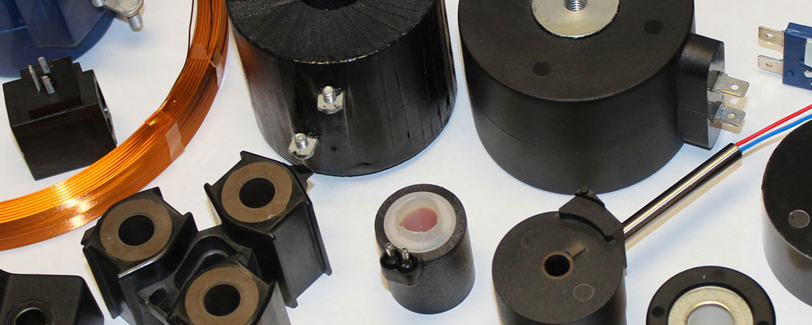

Electric coils are essential electromagnetic components that convert electrical energy into magnetic energy, and vice versa. They are found in countless applications, from electric motors and transformers to telecommunications and medical devices. The precision and reliability of electric coils are crucial to the performance of these systems.

Electric coil manufacturers play a critical role in ensuring that these components are designed, manufactured, and tested to meet the demanding requirements of various industries. Their expertise extends to customizing coils for specific applications, enabling innovation and progress in diverse sectors.

Diverse Applications

The versatility of electric coils is astounding, as they find use in an array of applications:

Electric Motors: Electric coils are integral to the operation of electric motors, providing the magnetic field necessary for motion in everything from household appliances to industrial machinery.

Transformers: Coils are key components in transformers, enabling the conversion of voltage levels in power distribution and ensuring the efficient transmission of electricity.

Communication Systems: Electric coils are used in radio transmitters, telecommunication equipment, and antennas, facilitating the transmission and reception of signals.

Healthcare Devices: Medical equipment such as MRI machines and defibrillators rely on precision coils for accurate diagnosis and treatment.

Automotive Industry: Electric coils are found in ignition systems, sensors, and solenoids, contributing to the safety and performance of vehicles.

The Manufacturing Process

Electric coil manufacturing is a meticulous process that demands precision and attention to detail. It typically involves the winding of insulated wire around a core material, which can be made of various materials such as iron, steel, or ferrite. The number of turns and the gauge of the wire are carefully calculated to achieve the desired electrical properties.

Modern manufacturing techniques employ automation and computer-aided design (CAD) to ensure consistency and accuracy. Rigorous testing is also a critical part of the process, as manufacturers need to verify that the coils meet performance specifications.

Customization and Innovation

Electric coil manufacturers understand that one size does not fit all. They often collaborate closely with clients to customize coils to meet specific requirements. Whether it's designing coils for a new medical device or optimizing coils for energy-efficient systems, manufacturers play a pivotal role in driving innovation across industries.

Their expertise in materials, winding techniques, and electromagnetic theory enables them to push the boundaries of what is possible, leading to the development of more efficient, compact, and reliable devices.

Contribution to Technological Advancements

Electric coil manufacturers are at the forefront of technological advancements. They contribute to the development of renewable energy systems, electric vehicles, advanced communication networks, and more. As industries continue to evolve, electric coil manufacturers are instrumental in creating components that enhance the efficiency, performance, and sustainability of the technologies we rely on.

For More Info:-

Trusted Electro-magnetic Coil Manufacture

Part time and full time manufacturing positions

Comments