In industries relying on controlled, contaminant-free environments, vacuum gate valves are indispensable. These valves regulate the flow of gases, maintaining the integrity of the vacuum within the chamber. Many vacuum chamber manufacturers incorporate advanced vacuum gate valve designs to enhance system efficiency and reliability. Precision in design and choice of components, such as vacuum gate valves, ensures optimal performance across various applications, from semiconductor manufacturing to scientific research.

Critical Role of the Vacuum Angle Valve

A vacuum angle valve is another essential component for vacuum systems, offering flexibility in gas control. These valves allow for smooth flow redirection while maintaining tight seals, making them ideal for chambers with complex piping layouts. Angle valves are commonly used in setups where rapid cycling between vacuum levels is required, such as in laboratory applications and industrial manufacturing processes. Their unique design minimises turbulence, helping maintain a stable vacuum.

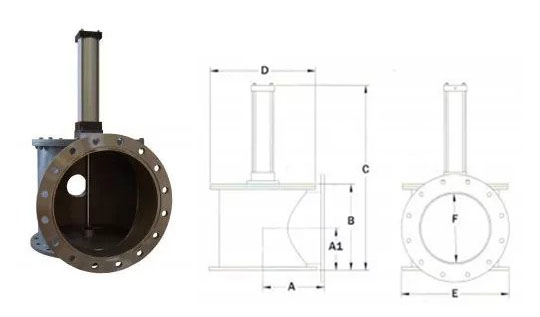

Vacuum Gate Valve Design for Enhanced System Performance

The vacuum gate valve design is crucial for high-precision applications. By ensuring a clean, tight seal, these valves prevent leaks, maintaining the vacuum’s purity and stability. Manufacturers like GNB KL Group focus on engineering gate valves that can withstand the stress of repeated cycles and high-pressure differentials, ensuring long-lasting reliability. Quality vacuum gate valves are essential in applications like coating and deposition processes, where even minor leaks can compromise results.

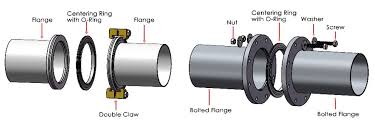

KF Vacuum Flange: Reliable Connections for High-Vacuum Systems

Reliable connection points are vital for any vacuum chamber setup, and the KF vacuum flange serves this purpose well. Known for its user-friendly assembly and reliable seal, the KF flange is often used in medium- to high-vacuum systems. This type of flange offers compatibility with various components, ensuring a stable and leak-proof setup, which is essential for applications requiring high precision.

GNB KL Group’s Commitment to Excellence

Leading vacuum technology providers, such as GNB KL Group, specialise in developing high-quality components tailored to specific industrial needs. From gate valves to angle valves and KF flanges, GNB KL Group prioritises quality and precision, ensuring that vacuum systems perform at their best. This dedication to excellence positions GNB KL Group as a trusted name in the vacuum chamber industry.

Conclusion

A well-functioning vacuum chamber depends on carefully selected components, including vacuum valves, angle valves, and KF flanges. These elements ensure that the chamber maintains a contaminant-free environment crucial to diverse applications, from scientific research to advanced manufacturing. Through innovative designs and robust materials, manufacturers continue to improve the efficiency and reliability of vacuum systems, supporting industries that rely on clean, controlled environments.

Visit Us Our Blog URL : - https://vacuumchamber8.blogspot.com/2024/10/key-components-of-vacuum-chambers-gate.html

Comments