Introduction:

Excavators are powerful and versatile construction machines that play a crucial role in various industries, including construction, mining, and agriculture. Behind their robust performance lies a complex system of components, and one key element contributing to their functionality is the final drive. In this article, we'll explore the significance of Final Drives for Excavators . their functions, common types, and the importance of regular maintenance.

What are Final Drives?

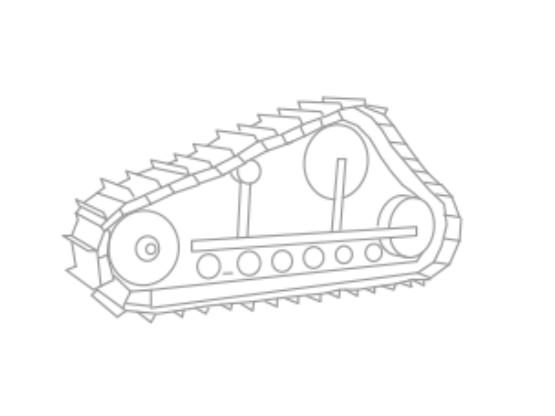

Final drives, also known as track motor or travel motor, are critical components of an excavator's powertrain system. They are responsible for translating power from the engine into the rotational force required to drive the tracks, enabling the excavator to move and operate efficiently on various terrains.

Functions of Final Drives:

Power Transmission: Final drives receive power from the engine and provide the necessary torque to turn the tracks, allowing the excavator to move forward, backward, and turn.

Directional Control: By controlling the speed and direction of each track independently, final drives enable precise maneuverability, crucial for navigating construction sites and performing intricate tasks.

Load Distribution: Final drives play a role in distributing the machine's weight across the tracks, ensuring optimal traction and stability, especially in challenging or uneven terrains.

Common Types of Final Drives:

Hydraulic Final Drives: Common in modern excavators, hydraulic final drives use hydraulic pressure to transmit power. These systems offer variable speed control, allowing for smoother and more precise movements.

Gearbox Final Drives: Traditional excavators may feature gearbox final drives, which utilize a combination of gears to transfer power. While simpler in design, they are generally found in older machine models.

Importance of Regular Maintenance:

Extended Lifespan: Proper maintenance, including regular lubrication and inspection, helps extend the lifespan of final drives, reducing the need for costly replacements.

Optimal Performance: Well-maintained final drives contribute to the overall performance and efficiency of the excavator, ensuring it operates at peak levels.

Cost Savings: Timely maintenance can prevent minor issues from developing into major problems, leading to significant cost savings in the long run.

Conclusion:

Final drives are integral to the functionality of excavators, enabling them to perform a wide range of tasks with precision and power. Understanding their importance and implementing a proactive maintenance routine ensures the longevity and optimal performance of these critical components, ultimately contributing to the success of construction and excavation projects.

Find out more today, visit our site:-

Comments