Selecting the right industrial fan for your warehouse is a critical decision that can impact air circulation, temperature regulation, energy efficiency, and employee comfort. Warehouse environments, characterized by vast spaces and high ceilings, require specialized fans designed to move air effectively across wide areas. With a range of industrial fan options available, it's essential to understand the key factors that influence the selection process. This guide will help you choose the right industrial fan for your warehouse by covering types of fans, benefits, and the most important considerations to keep in mind.

Why Industrial Fans Matter in Warehouses

Industrial fans play a vital role in maintaining a safe and comfortable working environment.warehouse ceiling fans Warehouses often face challenges like poor ventilation, uneven temperatures, and high humidity levels. Without proper airflow, these conditions can lead to discomfort, reduced worker productivity, and higher energy costs. Here are some of the primary benefits of installing industrial fans in a warehouse:

- Temperature Regulation: Large industrial fans help circulate air, preventing hot and cold spots in a warehouse. In summer, they can create a cooling breeze, reducing the perceived temperature and lowering the need for air conditioning. In winter, they help push warm air down from the ceiling, minimizing heating costs.

- Energy Efficiency: Industrial fans can work alongside HVAC systems to improve energy efficiency. By distributing air more evenly, they reduce the strain on heating and cooling units, lowering utility bills.

- Improved Air Quality: Proper air circulation is crucial for removing stale air, fumes, and airborne contaminants from the warehouse environment. Industrial fans enhance air quality, which is particularly important in warehouses that handle chemicals or materials that generate dust and particulates.

- Worker Comfort and Safety: A well-ventilated, temperature-controlled warehouse provides a safer and more comfortable working environment. This, in turn, boosts productivity and morale while reducing the risk of heat-related illnesses or fatigue.

Types of Industrial Fans

There are several types of industrial fans available for warehouses, each designed for specific applications and airflow requirements. Understanding the different fan types will help you make an informed decision.

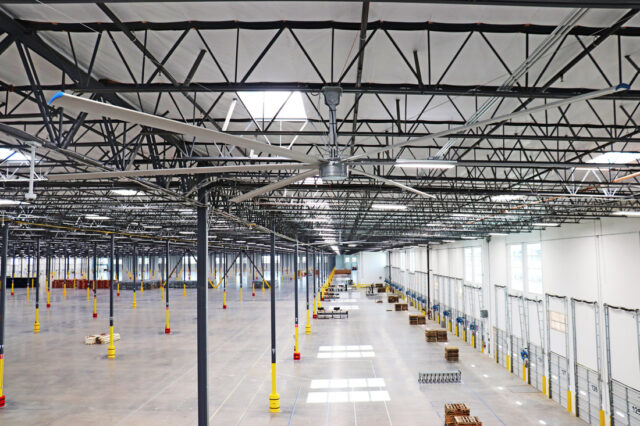

- High Volume, Low Speed (HVLS) Fans: HVLS fans are large ceiling-mounted fans designed to move a substantial volume of air at low speeds. These fans, which range from 7 to 24 feet in diameter, are ideal for large, open spaces with high ceilings. HVLS fans are energy-efficient and can help reduce heating and cooling costs by maintaining consistent airflow across the entire warehouse.

- Axial Fans: Axial fans work by drawing air along the axis of the fan and pushing it in the same direction. These fans are typically smaller and used for general ventilation, spot cooling, or exhausting air in specific areas. Axial fans are great for localized airflow but may not be sufficient for large spaces like warehouses.

- Centrifugal Fans: Centrifugal fans operate by pulling air into the center of the fan and then pushing it outward at a 90-degree angle. These fans are more powerful than axial fans and are often used in HVAC systems or applications requiring airflow through ducts. While effective at moving air over long distances, centrifugal fans can be noisier and less energy-efficient.

- Wall-Mounted Fans: For warehouses with limited ceiling space, wall-mounted industrial fans can provide a good solution. These fans can be installed on walls or support beams, allowing for flexible airflow direction. They are typically used in areas that require localized cooling or ventilation, such as near loading docks or workstations.

- Portable Industrial Fans: Portable fans are ideal for warehouses that need temporary or flexible airflow solutions. These fans can be moved to different areas as needed and are useful for spot cooling, drying, or directing air to specific locations within the warehouse.

Factors to Consider When Choosing an Industrial Fan

When selecting the right industrial fan for your warehouse, several factors should be taken into account to ensure the best fit for your space and needs.

1. Warehouse Size and Layout

The size and layout of your warehouse are critical in determining the appropriate fan size and type. Larger warehouses require larger fans to move air effectively across the entire space. Measure the square footage of your warehouse and the ceiling height to help identify the right fan size.

- Fan Diameter: For warehouses with high ceilings, HVLS fans are typically the best option, as they can move large volumes of air over wide areas. Smaller or wall-mounted fans may be more suitable for warehouses with lower ceilings or more confined spaces.

2. Ceiling Height

Ceiling height plays a crucial role in fan selection. HVLS fans are most effective in spaces with high ceilings, usually over 15 feet. If your ceiling is lower, smaller fans or wall-mounted options might provide better performance without creating excessive drafts.

3. Airflow Requirements

Consider the specific airflow needs of your warehouse. For general air circulation, HVLS fans provide excellent coverage. If you need targeted airflow in specific areas, such as workstations or high-traffic zones, smaller axial or wall-mounted fans can offer localized cooling.

- Air Changes Per Hour (ACH): Determine the number of times you need the air in your warehouse to be completely exchanged in an hour. This helps to calculate the airflow volume, measured in cubic feet per minute (CFM), that your fan needs to provide.

4. Energy Efficiency

Industrial fans can contribute significantly to energy savings if chosen correctly. HVLS fans, for example, operate at low speeds, reducing energy consumption while effectively circulating air. Look for fans with energy-efficient motors, variable speed settings, and programmable controls that allow you to optimize performance based on seasonal changes or specific work demands.

5. Noise Levels

In some warehouse environments, noise can be a concern, especially if communication or concentration is crucial. HVLS fans are known for their quiet operation, making them ideal for spaces where noise reduction is important. Axial and centrifugal fans may generate more noise, so they might not be suitable for every application.

6. Durability and Maintenance

Industrial fans must withstand tough working conditions, so durability is an essential consideration. Fans made from high-quality, corrosion-resistant materials will last longer in challenging environments. Additionally, opt for fans that require minimal maintenance and are easy to service when needed.

7. Control and Automation

Modern industrial fans often come equipped with advanced control options, such as remote control, variable speed settings, and integration with warehouse management systems. These features allow you to optimize airflow and energy use automatically, ensuring that your fans run efficiently without constant manual adjustments.

Conclusion

Choosing the right industrial fan for your warehouse is key to maintaining a comfortable, big industrial fans efficient, and productive environment. By considering the size of your space, ceiling height, airflow requirements, and energy efficiency, you can select a fan that meets the unique needs of your facility. Whether you opt for an HVLS fan to provide widespread coverage or a wall-mounted fan for localized cooling, the right industrial fan will enhance air quality, reduce energy costs, and improve worker comfort.

Comments