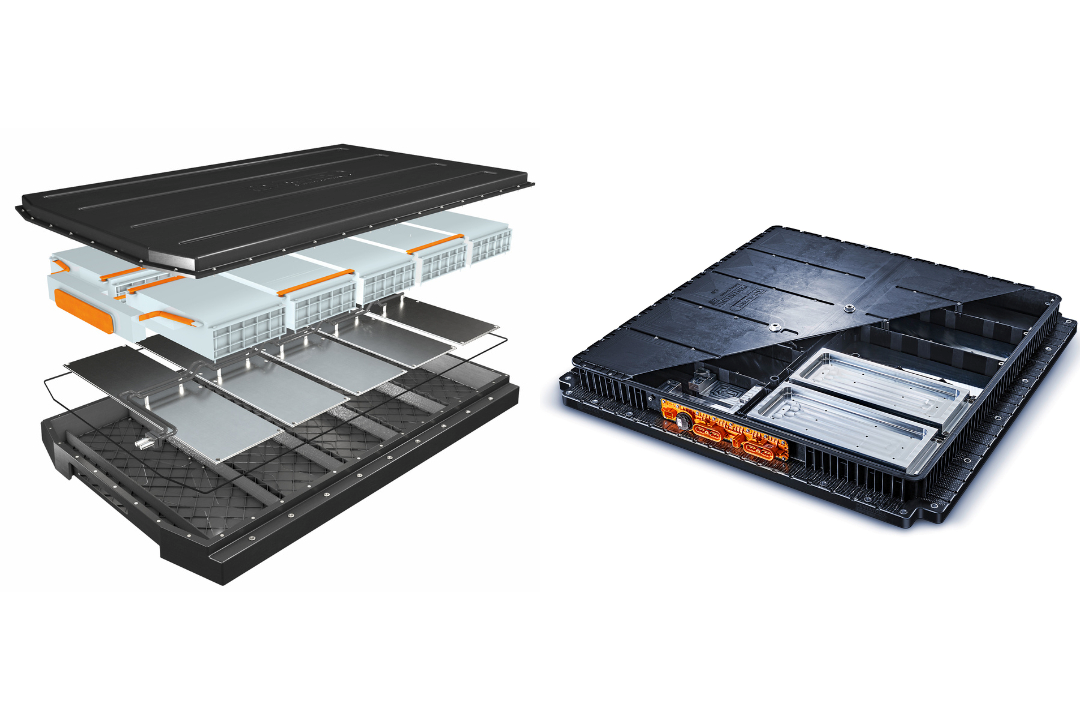

The global shift towards electric vehicles (EVs) has transformed the automotive industry in ways few could have imagined a decade ago. Among the most critical components of an EV is its battery enclosure — a protective housing that not only supports the structural integrity of the battery but also plays a major role in safety, thermal management, and overall vehicle performance.

One of the most promising materials used today in manufacturing these enclosures is through a technique called Prepreg Moulding. But what exactly is it, and why is it gaining so much attention, especially in the electric mobility space?

In this blog, we’ll take a closer look at Prepreg Moulding, explore how it’s revolutionising EV battery enclosures, examine emerging trends, and highlight real-world use cases that reflect the future of electric vehicle design.

Understanding Prepreg Moulding: A Quick Primer

Before diving into the trends, let’s start with the basics.

Prepreg stands for “pre-impregnated” composite fibres — typically carbon or glass fibres that are already infused with a partially cured resin system. These materials are stored under refrigerated conditions and are ready to be laid into a mould and cured under heat and pressure.

Prepreg Moulding is the process of shaping these materials into complex, high-strength parts using precision moulds, usually in an autoclave or heated press.

Why Prepreg for Battery Enclosures?

Here are a few reasons why prepreg composites are becoming the material of choice:

- Lightweight yet strong: Critical for EVs that need to maximise range and reduce weight.

- Excellent fire resistance: Certain resin systems used in prepregs can withstand high temperatures and delay thermal propagation in case of a battery fire.

- Superior surface finish and consistency: Important for enclosure fit and function.

- EMI shielding compatibility: Essential for electronics-heavy EV environments.

The Role of Prepreg Moulding in EV Battery Enclosures

Battery enclosures in electric vehicles aren’t just boxes to hold cells. They need to provide:

- Crash protection

- Fire and thermal insulation

- Structural stiffness

- Corrosion resistance

- Airtight sealing

Using Prepreg Moulding in these components enables engineers to address all of the above requirements in a single, integrated structure — without the weight penalties of metal counterparts.

Key Benefits of Prepreg Moulding for EV Applications

Let’s break down the benefits specifically in the context of electric vehicle battery enclosures:

1. Weight Reduction

In electric mobility, every kilogram saved translates into more kilometres of range. Prepreg carbon fibre enclosures can be up to 40–60% lighter than traditional aluminium housings.

2. Enhanced Fire Safety

Battery fires, although rare, can be catastrophic. Resin systems used in prepreg materials can be formulated for high thermal resistance and low smoke toxicity, offering an added layer of safety.

3. Design Flexibility

With Prepreg Moulding manufacturers can mould highly complex geometries that would be challenging with metals — enabling integrated brackets, channels, and cooling paths.

4. Corrosion Resistance

Unlike aluminium and steel, composite enclosures are not susceptible to rust, especially useful in coastal areas or high-humidity environments common in many Indian cities.

5. Sustainability

Prepreg parts are long-lasting and reduce overall environmental impact over the vehicle’s lifecycle. With cleaner resin formulations, even end-of-life recyclability is improving.

Emerging Trends in Prepreg Moulding for EV Battery Systems

🔹 Trend 1: Integration of Multiple Functions

Modern battery enclosures are no longer just containers. They now integrate cooling channels, cable management systems, and sensor mounts. Prepreg Moulding allows for this multi-functionality without adding assembly complexity.

🔹 Trend 2: Fire-Retardant Prepreg Formulations

Fire safety standards like UL 94 V-0, FMVSS 302, and ISO 6722 are pushing OEMs to explore prepreg materials with enhanced flame retardancy. Resins infused with ceramic fillers and intumescent additives are now being used more commonly.

🔹 Trend 3: Localised Manufacturing in India

With the Make in India initiative and a growing EV ecosystem, local manufacturers are investing in domestic Prepreg Moulding facilities. This cuts down lead times and reduces dependency on imported components.

🔹 Trend 4: Out-of-Autoclave (OOA) Techniques

To bring down costs and scale production, manufacturers are shifting from traditional autoclave curing to OOA processes like vacuum bag-only and heated press curing — without compromising on part quality.

Real-World Use Cases of Prepreg Moulding in EVs

Several automotive and two-wheeler EV manufacturers are already reaping the benefits of Prepreg Moulding in their battery enclosures:

🔸 High-Performance Electric Cars

Luxury EV brands have adopted carbon fibre prepreg enclosures to ensure rigid battery compartments, essential for performance and crash safety. The enclosures double up as a structural part of the chassis.

🔸 Electric Two-Wheelers and Scooters

In India's bustling two-wheeler segment, prepreg moulded housings offer lightweight protection without sacrificing strength, crucial for performance and cost-effectiveness.

🔸 Commercial EV Fleets

Electric delivery vans and buses use composite battery covers with thermal insulation layers — enabling longer battery life and improved operational safety in long-haul and high-temperature conditions.

Challenges and Considerations

While the benefits are undeniable, Prepreg Moulding does come with its own set of challenges:

- High initial tooling cost: But recoverable over volume production

- Requires skilled labour and equipment: Although automation is slowly bridging this gap

- Shelf-life sensitivity: Prepregs must be stored under specific conditions to retain performance

Despite these, the advantages far outweigh the limitations, especially as EV manufacturers move toward mass customisation and smarter design integration.

The Indian Advantage: Local Players Making a Mark

India’s growing EV manufacturing sector has opened up opportunities for companies offering advanced composite solutions. Datum Advanced Composites, for example, has been instrumental in developing lightweight, high-performance enclosures tailored to Indian climate and road conditions.

As battery design continues to evolve, the role of prepreg materials and precision moulding will become even more integral to electric vehicle platforms.

Final Thoughts: A Future Powered by Composites

The EV revolution is not just about batteries and motors — it’s about smart materials, efficient structures, and safe mobility. Prepreg Moulding, with its unique blend of strength, lightness, and versatility, is emerging as a silent enabler in this transformation.

Whether you're an OEM, a design engineer, or an EV enthusiast, understanding the value and application of this technology is crucial to staying ahead in a rapidly changing landscape.

Want to explore more on how prepreg composites can elevate your EV designs? Stay tuned to our blog for technical deep-dives, industry insights, and real-world engineering tips!

Comments