Bricks have been a fundamental building material for centuries, offering durability, strength, and versatility to construction projects. Among various types of bricks, solid bricks have gained significant popularity due to their exceptional strength and reliability. In this blog post, we will delve into the characteristics, manufacturing process, and applications of solid bricks, highlighting their importance in creating robust structures. Whether you're a homeowner, a contractor, or an aspiring builder, understanding the value of solid bricks will empower you to make informed decisions for your construction projects.

Characteristics of Solid Bricks

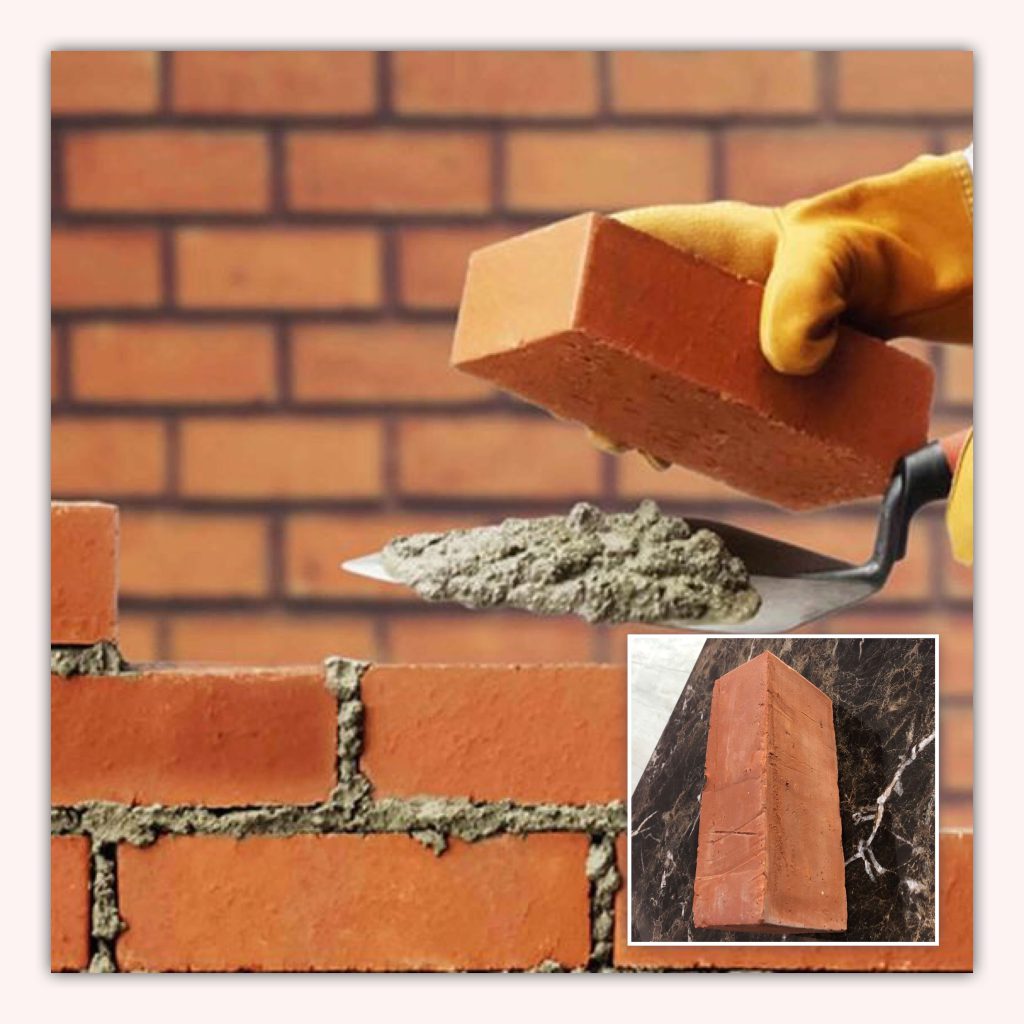

Solid bricks are manufactured from clay, shale, or other similar materials that are heated at high temperatures to fuse the particles together. These bricks are known for their dense and compact structure, which provides excellent compressive strength. Here are some key characteristics of solid bricks:

- Strength and Durability: Solid bricks possess high compressive strength, making them ideal for load-bearing structures. They can withstand heavy loads and resist damage caused by natural forces like wind, earthquakes, and moisture.

- Thermal Insulation: Solid bricks offer superior thermal insulation properties, helping to regulate indoor temperature and reduce energy consumption. Their dense composition limits heat transfer, keeping interiors cool in summer and warm in winter.

- Sound Insulation: The dense nature of solid bricks also contributes to their excellent sound insulation capabilities. They effectively block external noise, providing a peaceful and quiet environment indoors.

- Fire Resistance: Solid bricks are inherently fire-resistant due to their composition. They do not combust or release toxic fumes when exposed to high temperatures, making them a safe choice for construction in fire-prone areas.

Manufacturing Process of Solid Bricks

The manufacturing process of solid bricks involves several stages, ensuring their quality and uniformity. Here is an overview of the typical manufacturing process:

- Material Preparation: The raw materials, such as clay, shale, or a mixture of both, are gathered and prepared for processing. They are cleaned, crushed, and mixed with water to achieve the desired consistency.

- Molding: The prepared clay mixture is then molded into brick shapes using different techniques like extrusion or pressing. The molds determine the size and texture of the bricks.

- Drying: The molded bricks are dried to remove excess moisture. This process is crucial to prevent cracking and warping during firing.

- Firing: The dried bricks are fired in a kiln at high temperatures ranging from 900 to 1,100 degrees Celsius. This firing process ensures the fusion of clay particles and the development of strength and durability.

- Cooling and Quality Control: After firing, the bricks are allowed to cool gradually. Quality control checks are performed to ensure that the bricks meet the required standards for strength, dimensions, and appearance.

Applications of Solid Bricks

Solid bricks find extensive applications in various construction projects due to their numerous advantages. Here are some common uses:

- Residential Construction: Solid bricks are widely used in residential buildings, especially for load-bearing walls. Their strength and durability provide a solid foundation for structures, ensuring longevity and stability.

- Commercial and Industrial Buildings: Solid bricks are favored in the construction of commercial and industrial buildings where robustness and fire resistance are crucial. They are used for walls, partitions, and facades, offering reliable support and protection.

- Infrastructure Projects: Solid bricks are employed in infrastructure projects, including bridges, dams, and retaining walls, where their strength and ability to withstand external forces are paramount.

- Interior Walls: Solid bricks can be used as interior walls to provide thermal and sound insulation. They enhance the comfort and privacy of living and working spaces.

- Landscaping and Hardscaping: Solid bricks are utilized in landscaping and hardscaping projects, such as building pathways, driveways, and garden walls. Their durability ensures long-lasting structures that can withstand outdoor elements.

Conclusion

Solid bricks continue to be a trusted building material for construction projects, thanks to their exceptional strength, durability, and versatility. Their ability to withstand heavy loads, provide thermal and sound insulation, and resist fire makes them a reliable choice for both residential and commercial structures. Understanding the manufacturing process and applications of solid bricks equips builders, architects, and homeowners with the knowledge to make informed decisions and create robust, long-lasting buildings.

As you embark on your next construction project, consider the benefits of solid bricks and how they can contribute to the overall quality and resilience of your structure. By choosing solid bricks, you are investing in a strong foundation that will stand the test of time.

Comments