Introduction

Precision and efficiency are the cornerstones of success in the current engineering world. One of the main forces behind reaching these objectives has been the development of motors. A noteworthy development in this area is the brushless motor encoder.

Understanding Brushless Motors

Let's first gain a fundamental understanding of brushless motors before delving into the minutiae of their encoders.

What Is a Brushless Motor?

As the name implies, a brushless motor runs without brushes. Brushless motors use electronic commutation for increased efficiency and durability as opposed to conventional brushed motors, which depend on direct physical contact between brushes and a commutator.

The Role of Encoders

Let's examine how encoders affect the performance of brushless motors now that we have a basic understanding of them.

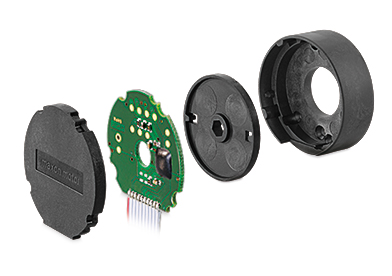

Brushless Motor Encoders: The Key to Precision

Encoders for brushless motors are crucial parts for applications that prioritise precision control. Why they are so important is as follows:

Precision Positioning

Encoders for brushless motors allow for fine control of the rotor position. This degree of precision is crucial in fields like robotics, CNC machinery, and medical equipment where precise positioning is essential.

Speed Control

Brushless motor encoders give real-time feedback to the controller in applications needing varied speeds, enabling quick and accurate adjustments.

Applications of Brushless Motor Encoders

Because of their adaptability, brushless motor encoders are crucial in a variety of fields and applications:

Robotics

Robots use brushless motor encoders to carry out tasks with a high degree of accuracy, such as assembling complex electronics or traversing unfamiliar areas.

Aerospace

Brushless motor encoders are essential in the aerospace sector for regulating the movements of aircraft parts and guaranteeing a safe and effective flight.

Automotive

Brushless motor encoders are used in hybrid and electric vehicles (EVs) to control the speed and positioning of various parts, which helps with energy economy.

Benefits of Brushless Motor Encoders

After looking at their uses, let's examine some benefits of using brushless motor encoders:

Enhanced Efficiency

Brushless motor encoders perform more effectively, using less energy, and producing less heat since there is no brush friction.

Extended Lifespan

Because there are no brushes, the motor and encoder last longer because there is less wear and tear.

Reduced Maintenance

Brushless motor encoders require little maintenance since they have fewer mechanical parts, which lowers downtime and operating expenses.

Precise Feedback

Encoders' real-time feedback guarantees accurate control, improving brushless motors' overall performance.

FAQs

Q: What is the primary function of a brushless motor encoder?

A: In a variety of applications, a brushless motor encoder offers feedback on the location and speed of the rotor, providing precise control.

Q: Why are brushless motor encoders essential in the aerospace industry?

A: Precision and safety are crucial in the aerospace industry. Encoders for brushless motors assist in controlling important elements to guarantee safe and effective flight.

Comments