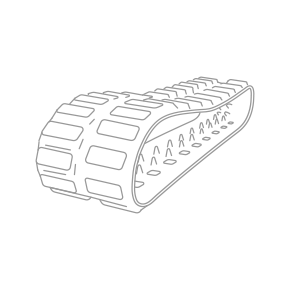

The rubber tracked dozer has become an essential machine in the construction industry due to its versatility and efficiency. Unlike traditional steel-tracked dozers, rubber tracks provide superior traction on soft, muddy, or uneven terrains, reducing slippage and increasing productivity. They are gentle on delicate surfaces, minimizing damage to roads, lawns, and finished landscapes, which makes them ideal for urban projects and landscaping jobs. Additionally, rubber-tracked dozers deliver a smoother ride, improving operator comfort during extended hours of operation. Their adaptability across various environments ensures they remain a preferred choice for professionals aiming for efficiency and reduced environmental impact.

Why the Dresser Dozer Remains a Reliable Workhorse

The Dresser dozer has built a solid reputation as a reliable and durable machine capable of handling the toughest construction, agriculture, and forestry tasks. Known for its robust build and advanced engineering, this dozer offers consistent performance across various applications. Dresser dozers are designed to easily handle heavy workloads, ensuring efficiency in earthmoving, grading, and clearing projects. Their reliability reduces downtime, making them valuable for contractors and operators who demand high productivity. Investing in a Dresser dozer ensures long-term performance and dependability in challenging work environments.

The Advantages of Rubber Tracked Dozers Over Steel-Tracked Alternatives

Choosing a rubber tracked dozer over a steel-tracked model offers numerous benefits, particularly when working on sensitive surfaces. Rubber tracks are quieter, ideal for urban areas or projects near residential zones. They reduce ground disturbance, preserving the integrity of lawns, pavements, and other delicate surfaces. Rubber tracks also provide better fuel efficiency by reducing the overall weight of the machine, lowering operating costs. Their enhanced traction on loose or uneven ground improves stability and performance. These advantages make rubber-tracked dozers a practical and cost-effective choice for various industries.

Maintaining Peak Performance of Your Dresser Dozer

Regular maintenance of a Dresser dozer is essential to ensure optimal performance and longevity. Routine inspections of the tracks, undercarriage, and hydraulic systems help identify potential issues early, preventing costly repairs. Cleaning the machine after use, especially when working in muddy or sandy conditions, reduces wear and tear on critical components. Following manufacturer guidelines for servicing and replacing worn parts ensures the dozer operates at its peak efficiency. Proper maintenance extends the machine's lifespan and enhances its reliability, allowing operators to handle demanding tasks with confidence and precision.

How to Choose the Best Dozer for Your Project Needs

Selecting the right dozer, whether a rubber-tracked model or a Dresser model, requires careful consideration of project requirements. Factors such as terrain type, workload demands, and surface sensitivity significantly influence the decision. Rubber-tracked models are ideal for projects requiring minimal surface damage, while Dresser dozer excel in heavy-duty applications. Consulting with industry experts or trusted suppliers ensures the chosen machine aligns with the job's specific needs. Investing in the right dozer boosts productivity, reduces operational costs, and guarantees the success of any project.

FOR MORE INFO :

Track Chain for Caterpillar Dozer

Comments