Liposuction has revolutionized the field of cosmetic surgery, offering patients effective body contouring solutions with minimal invasiveness. At the heart of this transformative procedure lies a crucial surgical instrument that determines the success and safety of the operation: the lipo cannula. This specialized tool has evolved significantly over the decades, becoming an indispensable component in achieving optimal surgical outcomes.

The importance of selecting the right cannula cannot be overstated, as it directly impacts patient safety, recovery time, and aesthetic results. Surgeons worldwide rely on these precision instruments to perform delicate fat removal procedures that require both technical expertise and high-quality equipment.

Understanding the Lipo Cannula Design and Functionality

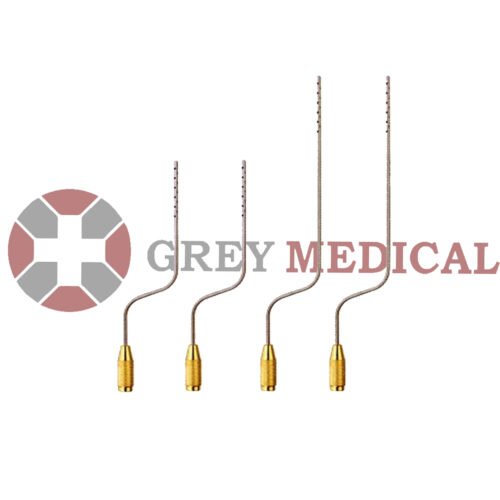

A lipo cannula represents a sophisticated piece of medical engineering designed specifically for fat extraction during liposuction procedures. These hollow, tube-like instruments feature a blunt tip with strategically placed openings that allow for controlled suction and fat removal while minimizing trauma to surrounding tissues.

The design typically includes several key components that work together to ensure safe and effective fat removal. The shaft provides stability and control during the procedure, while the tip configuration determines how the cannula interacts with fatty tissue. The side ports or openings are precisely positioned to create optimal suction patterns that facilitate smooth fat extraction without causing unnecessary damage to blood vessels or connective tissue.

Modern cannulas come in various diameters, lengths, and tip configurations to accommodate different surgical techniques and treatment areas. Smaller diameter cannulas allow for more precise work in delicate areas, while larger ones can efficiently remove greater volumes of fat from broader treatment zones. The length of the cannula is carefully selected based on the depth of fat deposits and the specific anatomical requirements of each procedure.

Material Science and Manufacturing Excellence

The manufacturing of surgical cannulas requires adherence to strict medical device standards and precise engineering tolerances. Companies like GreyMedical® have established themselves as leaders in this field, combining decades of experience with cutting-edge manufacturing processes to produce instruments that meet the demanding requirements of modern surgical practice.

High-quality cannulas are typically manufactured from medical-grade stainless steel or specialized alloys that offer superior strength, corrosion resistance, and biocompatibility. The surface finish must be meticulously smooth to prevent tissue trauma and ensure easy insertion through small incisions. Each lipo cannula undergoes rigorous quality testing to verify its dimensional accuracy, strength, and performance characteristics.

The precision required in manufacturing these instruments extends to every detail, from the exact positioning of suction holes to the precise angle of the tip. Advanced computer-controlled machining processes ensure consistency across production batches, while specialized finishing techniques create the smooth, polished surfaces that are essential for safe patient use.

GreyMedical®, as a privately owned medical technology company, maintains complete control over its manufacturing processes, allowing for continuous innovation and quality improvements. This approach ensures that each instrument meets the highest standards of surgical excellence while incorporating the latest technological advances in medical device manufacturing.

Clinical Applications and Surgical Techniques

The versatility of the lipo cannula makes it suitable for a wide range of cosmetic and reconstructive procedures. Beyond traditional liposuction, these instruments are used in fat transfer procedures, body sculpting techniques, and various minimally invasive aesthetic treatments. Each application requires careful consideration of cannula selection to achieve optimal results while maintaining patient safety.

Different surgical techniques utilize cannulas in specific ways to achieve desired outcomes. The tumescent technique, for example, requires cannulas designed to work effectively with the specialized fluid used to numb and prepare the treatment area. Power-assisted liposuction employs cannulas that can handle the mechanical vibration or rotation used to facilitate fat removal.

The selection of appropriate cannula size and configuration depends on multiple factors, including the treatment area, the amount of fat to be removed, and the patient’s individual anatomy. Facial procedures typically require much smaller, more delicate cannulas than those used for larger body areas. The surgeon’s experience and preferred technique also influence cannula selection, as different approaches may benefit from specific design features.

Recovery and healing outcomes are significantly influenced by the quality and appropriateness of the cannula used during surgery. High-quality instruments that create minimal tissue trauma contribute to reduced bruising, swelling, and discomfort during the healing process. This translates to shorter recovery times and improved patient satisfaction.

Innovation and Technological Advancement

The field of liposuction technology continues to evolve, with manufacturers constantly developing new cannula designs and features to improve surgical outcomes. Recent innovations include specialized coatings that reduce friction, advanced tip geometries that enhance fat removal efficiency, and ergonomic handle designs that reduce surgeon fatigue during lengthy procedures.

Computer-aided design and advanced manufacturing techniques have enabled the creation of cannulas with previously impossible precision and complexity. These technological advances allow for better customization of instruments to specific surgical needs and patient requirements.

Research and development efforts focus on creating cannulas that minimize tissue trauma while maximizing fat removal efficiency. This includes developing new materials, refining surface treatments, and optimizing geometric parameters based on clinical feedback and scientific research. The goal is to create instruments that deliver superior results while enhancing patient comfort and safety.

The integration of smart technology into surgical instruments represents an emerging frontier in medical device development. Future lipo cannula designs may incorporate sensors or other technological features that provide real-time feedback to surgeons, further enhancing precision and safety during procedures.

Quality Standards and Regulatory Compliance

Medical device manufacturing is subject to stringent regulatory oversight to ensure patient safety and device effectiveness. Reputable manufacturers must comply with comprehensive quality management systems and undergo regular inspections by regulatory authorities. These requirements ensure that every cannula meets established safety and performance standards before reaching surgical facilities.

The regulatory landscape for medical devices continues to evolve, with increasing emphasis on post-market surveillance and continuous monitoring of device performance. Manufacturers must maintain detailed records of production processes, quality testing results, and customer feedback to demonstrate ongoing compliance with regulatory requirements.

International standards such as ISO 13485 provide frameworks for quality management systems specifically designed for medical device manufacturers. These standards ensure consistent quality across different production facilities and help maintain the high standards expected in surgical instrument manufacturing.

GreyMedical®’s commitment to innovation and excellence in surgical instrument manufacturing reflects the industry’s dedication to advancing medical technology while maintaining the highest safety standards. This approach ensures that healthcare providers have access to reliable, high-performance instruments that support optimal patient care.

Conclusion

The lipo cannula stands as a testament to the precision engineering and medical expertise that define modern surgical instrumentation. From its carefully engineered design to the stringent manufacturing processes that ensure its quality, every aspect of this essential tool reflects the commitment to excellence that characterizes the best medical device companies.

As cosmetic surgery continues to advance and patient expectations evolve, the role of high-quality surgical instruments becomes increasingly critical. The ongoing innovation in cannula design and manufacturing, exemplified by companies like GreyMedical®, ensures that surgeons have access to the tools they need to deliver exceptional results safely and effectively.

For healthcare providers seeking to optimize their surgical outcomes, investing in premium cannulas from established manufacturers represents a crucial decision that impacts both patient satisfaction and practice success. The combination of advanced engineering, quality manufacturing, and ongoing innovation ensures that these essential instruments will continue to support the advancement of cosmetic surgery for years to come.

Comments