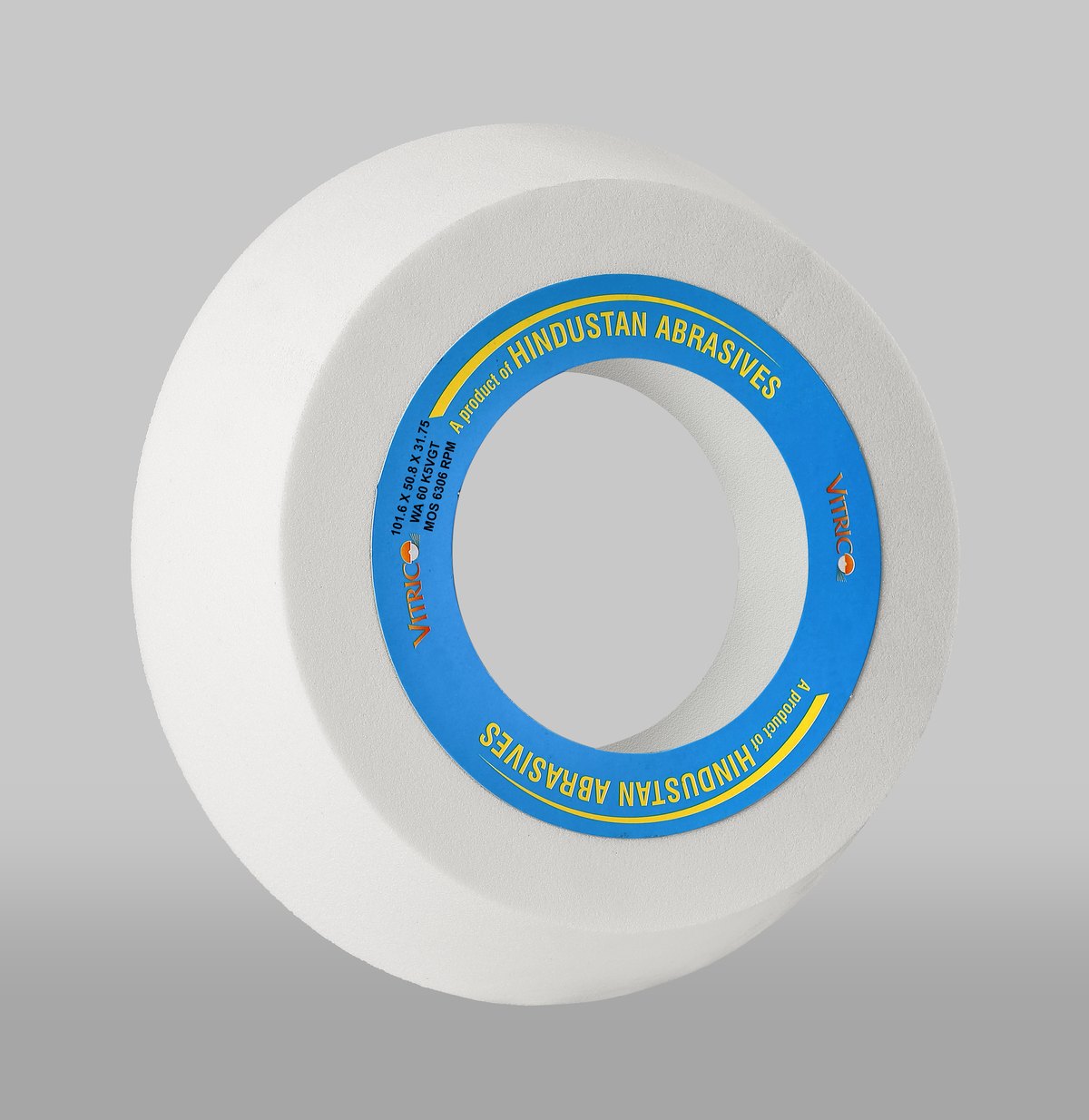

In the fast-paced world of metal fabrication and tool maintenance, precision and performance are more than just buzzwords—they're essential. At the core of high-quality grinding processes lies a simple but powerful tool: the grinding wheel. Among various types, white grinding wheels are particularly favored for their purity, sharpness, and smooth grinding finish.

If you're looking for a reliable White Grinding Wheels Manufacturer, this blog will walk you through everything you need to know—from how these wheels are made to what makes a manufacturer trustworthy.

🧱 What are White Grinding Wheels?

White grinding wheels are manufactured using White Aluminum Oxide (WA), a refined version of aluminum oxide that is highly friable and self-sharpening. Unlike brown aluminum oxide wheels, white variants are designed for cooler, faster, and cleaner cutting, making them ideal for:

- High-speed steel (HSS) tools

- Tool sharpening

- Fine grinding operations

- Heat-sensitive materials

They are extensively used in:

- Tool & die shops

- Machine maintenance units

- Precision metal fabrication

- Knife-making and blade sharpening workshops

🔍 Why Choose a Specialized White Grinding Wheels Manufacturer?

Not all grinding wheels are created equal. The quality of raw material, bonding agent, grain size, and manufacturing precision all contribute to the performance of the grinding wheel. Here’s why choosing a dedicated White Grinding Wheels Manufacturer makes a difference:

1. Consistency in Quality

Expert manufacturers use top-grade white aluminum oxide with optimal grain purity and uniformity. This ensures longer wheel life, consistent performance, and minimal wheel dressing.

2. Custom Manufacturing

Not every job requires a one-size-fits-all solution. A specialized manufacturer offers custom solutions in terms of:

- Grit size (e.g., 46, 60, 80, 120)

- Wheel hardness (soft, medium, hard)

- Wheel dimensions (diameter, thickness, bore size)

- Bond types (vitrified, resin, etc.)

3. Safety Compliance

A good manufacturer ensures their wheels meet or exceed international safety and quality standards like:

- ANSI B7.1

- ISO 9001:2015

- BIS (Bureau of Indian Standards)

- OSHA (Occupational Safety and Health Administration)

4. Expert Support

Trusted manufacturers don’t just sell wheels; they provide:

- Application support

- Safety training

- Troubleshooting guides

- Post-sales technical assistance

🔬 Manufacturing Process of White Grinding Wheels

Here's a glimpse into how professional white grinding wheels are made:

- Raw Material Selection: Pure white aluminum oxide grains are selected based on grain size and friability.

- Mixing: The grains are mixed with bonding agents (like vitrified or resin bonds).

- Molding & Pressing: The mixture is shaped into wheels using high-pressure hydraulic presses.

- Firing: Wheels are fired in kilns at high temperatures to harden and bond the abrasive particles.

- Finishing & Inspection: The wheels are balanced, dressed, and inspected for surface quality and structural integrity.

Comments