Time is of the essence at a busy warehouse. Precise timing is essential due to incoming packages, shifting inventory, and pressing deadlines. It won't matter how hard your team works if they are unable to access the correct pallet at the correct moment or if storage becomes an issue. In situations like these, the utilization of articulated forklifts and a warehouse racking system that has been intelligently built can be enormously beneficial. They elevate your entire operation, not just the goods.

Articulated Forklifts Are The Flexible Giants for Tight Spaces

Not every lift truck needs an articulated forklift. Because of its exceptional flexibility, it can reach areas that standard forklifts can't, making it ideal for tight aisles and high stacks. Articulated forklifts offer the reach without sacrificing quality, making them ideal for warehouses featuring constrained space constraints.

In contrast to regular trucks, they can maneuver around intricate layouts, pivot in the middle of an aisle, and reach pallets located far up in high racks. The result is reduced stress for operators during maneuvers, quicker pick times, and a decrease in crashes. The outcome of this? A more efficient warehouse that makes the most of vertical space while avoiding risks and moving at a faster pace.

For Reach Trucks, Accuracy Meets Elevation

When used in conjunction with articulated forklifts, reach trucks are ideal. Teams can stack pallets high with stability and control thanks to their focus on vertical excellence. When combined with an efficient warehouse racking system, reach trucks make sure that every cubic meter of space is used productively. Operators can now safely recover merchandise from several meters above the ground, transforming previously inaccessible areas into routine training grounds.

Reliability and accuracy are key features of these equipment. Workflow is accelerated, errors are minimized, and stock damage is decreased with each lift and deposit. Together with articulated forklifts, they form a synergy of reach and flexibility that allows them to effortlessly handle both heavy loads and fragile products.

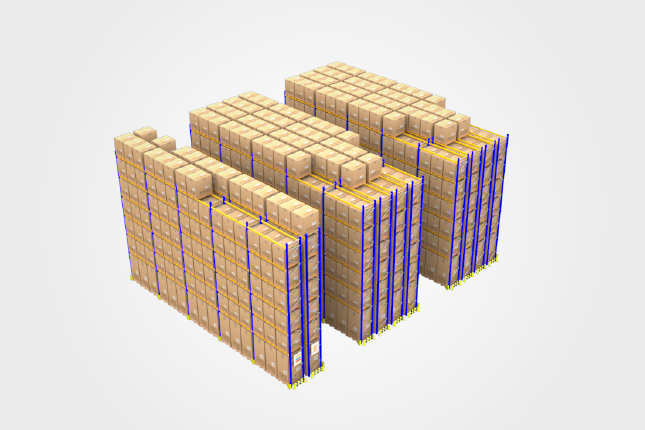

The Foundation of Efficient Smart Storage

The warehouse racking system is not only a shelving system; rather, it is the structure that supports productivity. Whether it's drive-in racks that maximize density or selective racks that provide rapid access to every SKU, the correct setup may transform disorder into order. With the help of modular and adaptable racking, your warehouse can easily adjust to different product sizes and inventory amounts with no downtime.

Planning more intelligently is more efficient than simply piling higher. Warehouse workers are able to transfer stock in predictable patterns thanks to racks placed strategically, reach trucks, and articulated fork lifts. You can save time, space, and money by reducing the number of unnecessary steps, improving workflows, and easing congestion.

Finally

Optimal warehouse performance is directly correlated to the level of intelligence displayed in its storing and lifting practices. It is possible to transform space into efficiency, height into productivity, and chaos into control by making an investment in the appropriate articulated forklifts, optimizing your warehouse racking system, and utilizing reach trucks properly.

.jpg)

Comments