Turret punching machines are vital tools in metal fabrication. They help shape and cut materials with precision. However, many users make mistakes that can lead to costly errors. This blog will explore common pitfalls to avoid when using turret punching machines.

We will also highlight the importance of using the best tool parts in Alberta for optimal performance.

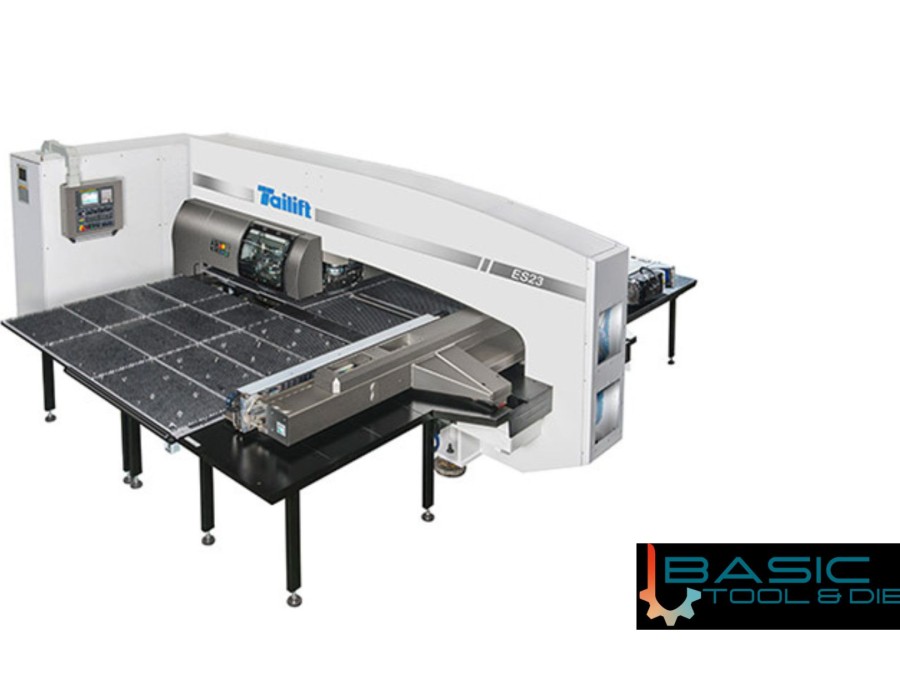

Understanding Turret Punching Machines

A turret punching machine uses a rotating turret to hold various punching tools. This allows it to make different shapes and holes in metal sheets. The machine is programmed to perform tasks automatically. This enhances efficiency in manufacturing. However, to get the best results, operators need to avoid common mistakes.

1. Ignoring Safety Protocols

One of the biggest mistakes in any machine operation is ignoring safety protocols. Operators must wear proper safety gear, including goggles and gloves. Not following safety guidelines can lead to injuries. It is essential to familiarize yourself with the machine’s safety features. Always keep the work area clean and organized to prevent accidents.

2. Poor Tool Selection

Choosing the wrong tools for the job can affect the quality of the final product. Always use the best tool parts in Alberta that suit your specific needs. Using improper tools can lead to poor cuts and excessive wear on the machine. Ensure you have the right punching tool for the material you are working with.

3. Neglecting Regular Maintenance

Regular maintenance is crucial for the longevity of turret punching machines. Many operators neglect this aspect, leading to machine failure. Ensure you follow a maintenance schedule that includes cleaning, lubrication, and part replacement. Regular checks can prevent minor issues from becoming significant problems, thus ensuring the machine runs smoothly.

4. Not Training Operators Properly

Training is vital for anyone operating a turret punching machine. Lack of knowledge can lead to improper use, resulting in mistakes. It is essential to provide thorough training on how to operate the machine effectively. This includes programming, tool changes, and troubleshooting. Skilled operators are less likely to make costly errors.

5. Overloading the Machine

Every turret punching machine has a maximum capacity. Overloading the machine can lead to severe damage and costly repairs. Operators should always be aware of the machine’s limits. Adhering to these specifications ensures the machine performs optimally and prolongs its lifespan.

6. Skipping Setup Checks

Before starting a job, it is crucial to check the setup of the turret punching machine. Skipping this step can lead to significant errors in production. Operators should verify that tools are correctly installed and the machine is calibrated. Ensuring everything is set up correctly saves time and prevents wasted materials.

7. Underestimating Material Variability

Different materials can behave differently during the punching process. Operators should understand the characteristics of the materials they are using. Some materials may require specific tooling or settings. Ignoring these variations can lead to subpar results. It is essential to adjust settings based on the type of metal being punched.

8. Poorly Managed Workpiece Orientation

Proper orientation of the work piece is crucial for accurate punching. Misalignment can lead to incorrect cuts and wasted materials. Operators should double-check the orientation before starting the machine. Using guides or jigs can help maintain proper alignment, improving overall production quality.

9. Failing to Use a Proper Programming Strategy

Programming is a critical aspect of operating turret-punching machines. Failing to use an efficient programming strategy can lead to wasted time and materials. Operators should plan the sequence of operations carefully. This will minimize tool changes and optimize production efficiency.

10. Not Tracking Production Data

Tracking production data helps identify patterns and potential issues. Many operators fail to keep a record of their machine’s performance. Monitoring data such as cycle times, downtime, and error rates can provide valuable insights. This information can help in making necessary adjustments and improving overall efficiency.

Final Thoughts

Using turret-punching machines can greatly enhance manufacturing efficiency. However, avoiding common mistakes is crucial for optimal performance. By following safety protocols, maintaining the machine, and selecting the best tool parts, operators can achieve better results. Proper training and awareness of common pitfalls will help minimize errors. With attention to detail and careful operation, the benefits of turret punching machines in Alberta can be fully realized, leading to higher productivity and reduced costs.

Comments