Introduction

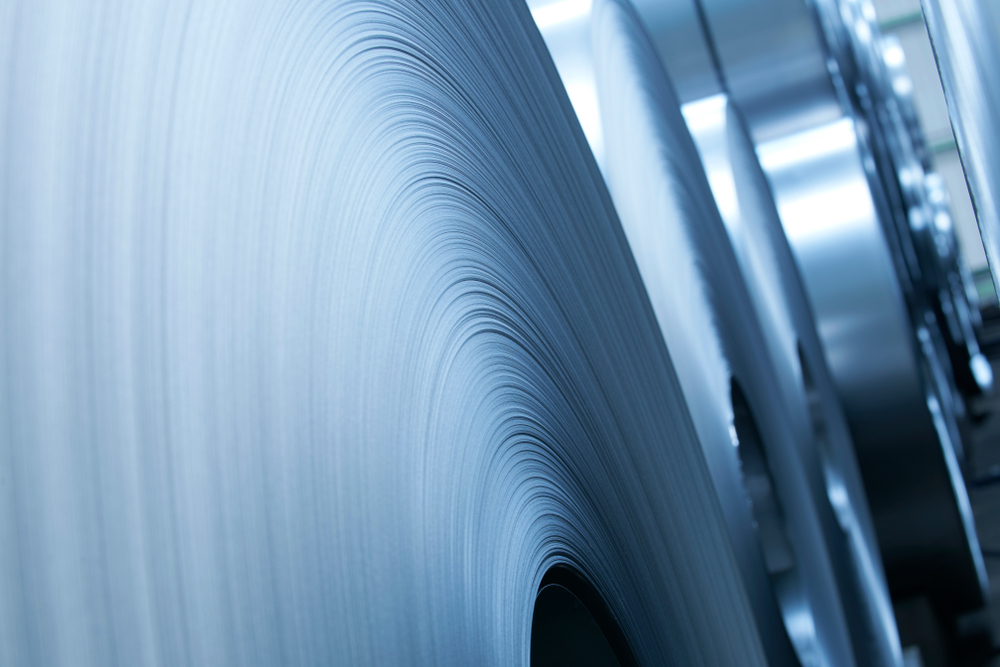

Welcome to a detailed exploration of 3003 aluminum coil, a highly sought-after material known for its versatility, durability, and excellent corrosion resistance. In this article, we'll delve into the various applications and benefits of using 3003 aluminum coil, along with its properties and how it compares to other aluminum alloys.

Whether you're in the construction, automotive, aerospace, or electronics industry, understanding the advantages of 3003 aluminum coil can significantly impact your projects' success. So, let's dive right in!

3003 Aluminum Coil: Overview and Applications

3003 aluminum coil belongs to the 3xxx series of aluminum alloys, which are known for their excellent formability, weldability, and corrosion resistance. This alloy is primarily composed of aluminum, manganese, and a few other elements, making it ideal for various industrial and commercial applications.

1. Versatile Use in Construction Industry

In the construction industry, 3003 aluminum coil finds widespread use due to its lightweight nature and exceptional strength. From roofing and siding to gutters and downspouts, this alloy proves its worth in protecting buildings from the elements while ensuring longevity.

2. Automotive Applications

The automotive industry also benefits from 3003 aluminum coil's attributes. Its formability allows for the fabrication of intricate parts, while its corrosion resistance ensures the longevity of components exposed to harsh environmental conditions.

3. Aerospace and Aviation Advantages

The aerospace and aviation sectors rely on Aluminium 3003 Coils for its lightweight yet robust properties. From aircraft panels to fuel tanks, this alloy plays a crucial role in enhancing fuel efficiency and overall performance.

4. Electrical and Electronics Usage

In the electrical and electronics industry, 3003 aluminum coil serves as an excellent conductor while being non-magnetic. This makes it an ideal choice for manufacturing electrical enclosures, heat sinks, and other components that require thermal conductivity.

5. Marine Applications

3003 aluminum coil's corrosion resistance extends to marine environments, making it a preferred material for boat hulls, decks, and other marine components. Its resistance to saltwater ensures longevity and reliable performance even in harsh conditions.

Properties of 3003 Aluminum Coil

Before diving deeper into its applications, let's explore the essential properties that make 3003 aluminum coil a go-to material for various industries.

6. Formability and Workability

3003 aluminum coil exhibits excellent formability and workability, allowing it to be easily bent, formed, or shaped into desired configurations without compromising its structural integrity.

7. Weldability and Joining Capabilities

This aluminum alloy possesses remarkable weldability, making it convenient for joining with other materials through various welding processes like MIG and TIG welding.

8. Corrosion Resistance

One of the standout features of Aluminium 3003 Coils is its exceptional resistance to corrosion, particularly in marine and acidic environments, making it a reliable choice for outdoor and long-lasting applications.

9. Thermal Conductivity

3003 aluminum coil demonstrates excellent thermal conductivity, making it valuable in applications where heat dissipation is essential, such as heat sinks and electronic enclosures.

10. Surface Finish and Aesthetics

With its smooth and attractive surface finish, Aluminium 3003 Coils not only performs well but also adds a touch of aesthetics to the finished products, making it a popular choice for architectural applications.

Comparison with Other Aluminum Alloys

3003 aluminum coil is often compared with other aluminum alloys like 5052, thanks to their similar compositions and properties. While 3003 offers better corrosion resistance, 5052 has slightly higher strength and better fatigue resistance. The choice between the two depends on specific project requirements.

Advantages of Choosing Aluminum 3003 Coil

13. Long-Lasting Durability

3003 aluminum coil's corrosion resistance and robustness ensure that products made from this alloy last for an extended period, reducing maintenance and replacement costs.

14. Cost-Effective Solution

Considering its exceptional performance and longevity, 3003 aluminum coil provides a cost-effective solution for various applications, offering value for money to businesses and industries.

15. Environmentally Friendly

Aluminum is a recyclable material, and 3003 aluminum coil is no exception. Opting for this alloy promotes sustainability and reduces environmental impact.

How 3003 Aluminum Coil Benefits Various Industries?

Let's take an in-depth look at some of the industries that extensively utilize 3003 aluminum coil and the specific benefits it offers.

16. Construction Industry: Durable and Low-Maintenance Solutions

In the construction industry, Aluminium 3003 Coils finds versatile use due to its excellent corrosion resistance, lightweight, and ease of installation. It is widely used in roofing, siding, and facades, providing durable and low-maintenance solutions for commercial and residential buildings.

17. Automotive Sector: Enhancing Performance and Fuel Efficiency

Automotive manufacturers opt for 3003 aluminum coil in various applications, including body panels, hoods, and heat shields. The alloy's lightweight nature contributes to fuel efficiency, while its corrosion resistance ensures long-lasting performance, even in adverse weather conditions.

18. Aerospace and Aviation: Ensuring Safety and Reliability

In the aerospace and aviation industries, safety and reliability are paramount. Aluminium Alloy 3003 Coil meets these requirements with its exceptional strength-to-weight ratio, corrosion resistance, and ease of fabrication. From aircraft structural components to fuel tanks, this alloy enhances overall performance and ensures passenger safety.

19. Electrical and Electronics: Efficient Thermal Management

3003 aluminum coil's excellent thermal conductivity makes it a top choice for manufacturing heat sinks and electronic enclosures. By efficiently dissipating heat, it prevents electronic components from overheating, improving device reliability and longevity.

20. Marine Applications: Resisting Harsh Marine Environments

Marine environments subject materials to harsh conditions, including saltwater exposure. Aluminium Alloy 3003 Coils resistance to corrosion in such environments makes it an ideal material for boat hulls, decks, and other marine components, ensuring durability and longevity.

For more information Visit Us.

Comments