In an aluminum smelting plant or metallurgy-based processing plants, the use of furnace is quite rampant. The furnaces operate at very high temperature to produce the conditions required for removal of metals from ores, or for meeting the industrial heating requirements. These work the best when are not kept covered as much long as possible. However, the productivity of a furnace decreases when the product build-up accumulates in larger quantity, which also causes the waste of metal. To ensure that such things don’t happen, the furnace tending vehicle is used.

What is a furnace tending vehicle?

A furnace tending vehicle is applicable in charging cold metal to the furnace so that it can be exposed to hot temperatures for further processes. During the extraction process, the action of skimming and stirring the molten metal is also performed by the tending vehicle. Thus, it is helpful in the core smelting process and helps keep the furnace functional for a very long time. By using the tending vehicle for furnace, the high temperatures can be maintained in it and the product build-up can be prevented.

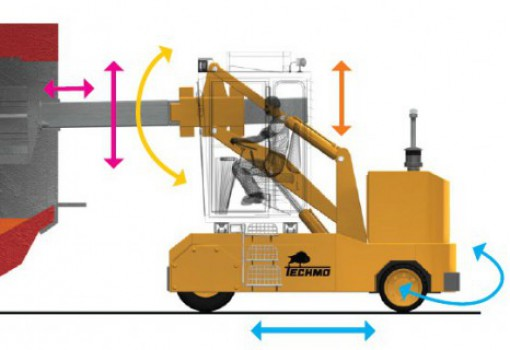

The tending vehicle comprises a telescopic boom and fork tilter and spreader that collectively allow handling the metal ore at high working temperature maintained in the furnace while keeping the handler unexposed to it. Even the design is made such that only the metallic portions of the tending vehicle are exposed to heat. Thus, the safety parameters are met effectively while ensuring the completion of process to perfection.

Main advantages of tending vehicles and charging cars

The furnace charging car and tending vehicle are an important part of a metal smelting plant. These vehicles serve very important purpose, and that is, of keeping the furnace functional for extended periods. The main advantages of using this equipment are:

· Provides the driver maximum control

The furnace charging car is a smart and efficient vehicle, which offers full control to the driver. Owing to the easily maneuverable fork lifters and tilters, the users can handle the molten metal inside the furnace at high temperatures. Thus, the process of mixing and skimming can be carried out with precision; such is its design.

· Helps keep the furnace clean

A furnace may not be able to maintain high temperatures if the product build-up is not scraped from the walls from time to time. The charging car does the job of scraping the product from the walls and surface of furnace. As a result, the furnace works well for extended periods and the manufacturing unit does not face a downtime.

· Saves metal wastage

Since the metal may go waste when not skimmed on time, the charging car may help avoid the metal wastage by enabling timely action. Dross skimming, bottom cleaning and side wall scraping prevent metal wastage, and so, it can help maximize the output.

To conclude,

The tending vehicles and charging cars for furnaces are designed to complement the unusual conditions found in the furnace. These help to keep the furnace well-maintained and prevent metal wastage. Easy maneuverability and ability to service furnace from a safe distance help meet the safety parameters at the smelting plant too.

Comments