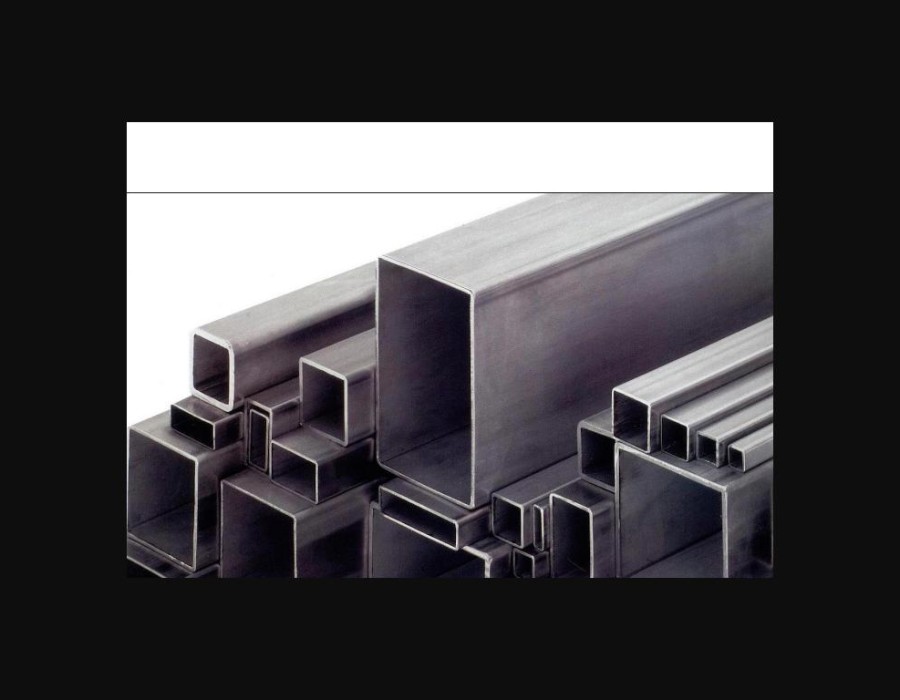

MS square and MS Rectangular Pipe, also known as mild steel hollow sections, are versatile building materials used across various industries, from construction and engineering to furniture and fabrication. Choosing the right pipe for your project can significantly impact its success, ensuring both functionality and structural integrity. At JRS Iron and Steel Pvt. Ltd., we understand the importance of selecting the appropriate pipe and are here to guide you through the process.

Understanding Your Needs

Before diving into specifics, clearly define your project's purpose and requirements. Ask yourself:

· What is the application of the pipe? Is it for structural support, framing, decorative elements, or something else?

· What loads will the pipe bear? Consider static and dynamic loads, weight distribution, and safety margins.

· What are the space constraints? Measure available space to determine fitting dimensions and lengths.

· What aesthetic considerations are there? Will the pipe be visible, and does it need a specific finish?

· What is your budget? Balance cost with quality and performance requirements.

Key Factors to Consider

Material

· Mild Steel: The most common choice, offering affordability and good weld ability.

· High-Strength Steel: Provides higher strength-to-weight ratio for demanding applications.

· Stainless Steel: Offers excellent corrosion resistance for outdoor or wet environments.

· Aluminum: Lightweight option with good corrosion resistance, though less sturdy than steel.

Size

· Dimensions: Consider width, height, and thickness based on load-bearing requirements and space constraints. JRS Iron and Steel Pvt. Ltd. offers a wide range of standard sizes, and custom sizes can be discussed for specific projects.

· Thickness: This directly impacts strength and rigidity. Thicker pipes handle heavier loads but may be bulkier. Consider using high-strength steel for thinner pipes with comparable strength.

Manufacturing Process

· Seamless: Produced by extruding a solid billet, resulting in a smooth, continuous wall with superior strength and pressure resistance.

· Welded: Made by forming a sheet into the desired shape and welding the seam. Available in various grades based on weld quality and strength.

Surface Treatment

· Galvanized: Zinc coating for enhanced corrosion resistance, suitable for outdoor applications.

· Painted: Provides aesthetic appeal and additional protection against corrosion.

· Untreated: The most economical option, suitable for indoor applications with minimal corrosion risk.

Quality and Standards

· Choose reputable suppliers like JRS Iron and Steel Pvt. Ltd., who adhere to national and international standards.

· Look for certifications like BIS or ASTM for guaranteed quality and consistency.

· Inspect the pipes for surface defects, weld integrity, and dimensional accuracy.

Additional Tips

· Consult with structural engineers or experienced professionals for complex projects.

· Request material test reports from your supplier to verify properties.

· Consider future expansion or modifications when choosing pipe sizes and types.

· JRS Iron and Steel Pvt. Ltd. offers expert advice and comprehensive product information to assist you.

By following these guidelines and working with trusted suppliers like JRS Iron and Steel Pvt. Ltd., you can confidently choose the right MS Square Pipe and rectangular pipe for your project, ensuring durability, performance, and value.

We encourage you to contact our team with any questions or specific requirements. We are committed to providing the best possible support and helping you achieve your project goals.

Company: JRS Iron And Steel Pvt. Ltd.

Mobile No: 9643470943

Address: Shop No. 5, Plot No. 66, Prakash Industrial Estate, Sahibabad Industrial Area Site 4, Sahibabad, Ghaziabad, Uttar Pradesh 201005

Website: https://jrsironandsteel.com

Comments