Industrial mold manufacturing is a crucial component of modern manufacturing. It spans across various industries, from automotive manufacturing to electronics, from medical devices to household goods, permeating every aspect of production.

Industrial mold manufacturing, in essence, involves the conversion of well-designed product prototypes into usable physical molds through specific techniques and processes. These molds can be utilized in various manufacturing processes such as plastic injection molding, die casting, rubber compression molding, significantly enhancing production efficiency and product quality. In the industrial realm, mold manufacturing is regarded as the "magic source" of manufacturing because it directly determines the quality of product molding and production efficiency.

Overview of Industrial Mold Manufacturing Process

The process of industrial mold manufacturing begins with product design. Designers create virtual models of products using Computer-Aided Design (CAD) software based on client requirements and product specifications. The key in this phase lies in ensuring the accuracy and manufacturability of the design to facilitate subsequent machining processes smoothly.

Next comes mold design. Mold designers translate product designs into feasible mold structures. This involves determining parameters such as the shape, size, material, and opening-closing mechanism of the mold. The quality of mold design directly impacts the quality and production efficiency of the final product.

Once mold design is completed, it proceeds to the stage of material selection and procurement. Suitable materials are chosen for manufacturing based on the specific requirements and usage environment of the mold. This may involve selecting metal materials, plastic materials, or even composite materials to ensure that the mold possesses sufficient strength, wear resistance, and corrosion resistance.

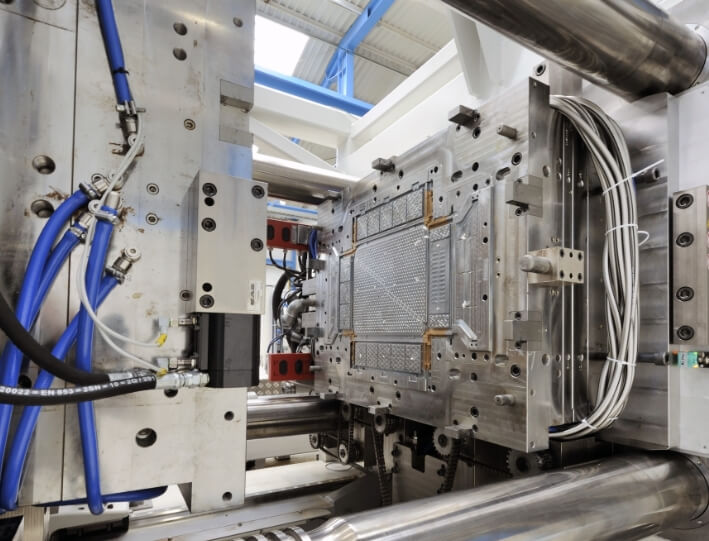

Subsequently, mold machining takes place, which is the most critical step in the industrial mold manufacturing process. Using Computer Numerical Control (CNC) machine tools and other precision machining equipment, selected materials are processed into the physical form of the mold. This requires a high level of technical expertise and experience to ensure the precision and surface quality of the mold.

Finally, mold debugging and testing are conducted. Completed molds undergo rigorous debugging and testing to verify their performance and stability. This may involve assembly, adjustment, and mold trial steps to ensure that the mold operates smoothly and meets the requirements of product production.

The industrial mold manufacturing process is a complex and precise endeavor, involving the integration of multiple steps and specialized technologies. Only by striving for excellence in each stage can high-quality and efficient mold products be produced, providing solid support for the development of modern manufacturing.

Industrial Mold Manufacturing Process Flow

The mold manufacturing process flow is the core of industrial mold manufacturing, determining the specific steps and procedures from design to production of the mold. In this section, we will elaborate on the typical process of mold manufacturing to help readers understand the importance and interrelationship of each stage.

Mold Design Phase: Designers use CAD software to create virtual models of products and translate them into feasible mold designs. This includes determining key parameters such as the structure, size, accessories, and opening-closing mechanism of the mold. Excellent mold design requires consideration of both product functionality and appearance, as well as the convenience of mold manufacturing and usage.

Mold Machining Phase: Mold machinists use design drawings and specifications to process selected materials into the physical form of the mold using CNC machine tools and other precision machining equipment. This may involve various machining processes such as milling, turning, and grinding to ensure that the mold has high precision and good surface quality.

Mold Assembly and Debugging Phase: Completed molds undergo strict assembly and debugging to ensure the coordinated operation of various components and the normal operation of the mold. This may include component assembly, mold opening-closing testing, cooling system debugging, etc., to ensure that the mold meets the requirements of product production.

Mold Testing and Validation Phase: Completed and debugged molds undergo rigorous testing and validation to verify their performance and stability. This may include mold trials, inspection of production samples, mold life testing, etc., to ensure that the mold meets the continuous production requirements of products.

The mold manufacturing process flow covers multiple stages including mold design, machining, assembly, debugging, testing, etc., each of which is crucial. Only by striving for excellence in each stage can high-quality and efficient mold products be produced, providing reliable support for the development of modern manufacturing.

Applications of Industrial Mold Manufacturing

Automotive Manufacturing Industry: Automotive manufacturing is one of the primary application areas of industrial mold manufacturing. In the automotive manufacturing process, molds are used to produce various components of automobiles, including body, engine parts, interior decoration parts, etc. The quality and precision of automotive molds directly affect the performance and quality of automobiles, making stringent requirements on molds in automotive manufacturing.

Electronics Manufacturing: With the continuous popularization and upgrading of electronic products, the demand for molds in electronic product manufacturing is also increasing. Molds are widely used in the production of electronic product casings, keyboards, connectors, and other components. The miniaturization and precision requirements of electronic products necessitate molds with higher machining precision and surface quality.

Medical Device Manufacturing: Medical device manufacturing requires high product safety and hygiene, thus special attention is paid to material selection and machining processes of molds. Molds are commonly used in the production of various medical device casings, pipes, connectors, and other components.

Other industries such as household goods manufacturing, daily necessities manufacturing, construction materials manufacturing, etc., also rely on industrial mold manufacturing support. Molds are used in these industries to produce various plastic products, metal products, rubber products, etc., providing essential and convenient products for people's daily lives.

Hopo's Leading Industrial Mold Manufacturing Technology

Hopo has several outstanding features in industrial mold manufacturing technology:

Technological Innovation: Hopo emphasizes technological innovation and research and development investment, continuously introducing and applying advanced CAD/CAM technology, mold design software, and precision machining equipment. Through digital design and intelligent manufacturing, Hopo can provide high-precision and complex mold products to meet the changing demands of customers.

Quality Control: Hopo strictly implements quality control standards in every aspect of mold manufacturing, from material procurement to machining and final product inspection, ensuring that each process meets customer requirements and industry standards. With a complete quality management system and testing equipment, Hopo can promptly identify and solve quality problems in the production process, ensuring product stability and reliability.

Professional Team: Hopo has a team of highly skilled and experienced professionals, including mold designers, machining process engineers, quality control engineers, etc., in various fields. These professionals not only have solid theoretical knowledge and technical expertise but also have rich practical experience and problem-solving abilities, capable of providing customers with comprehensive mold solutions and technical support.

Customer Service: Hopo always prioritizes customer needs, adhering to the principle of "customer first, quality first", and providing customers with customized and personalized mold solutions. Whether it's product design, machining, or after-sales service, Hopo can promptly respond to customer needs, ensuring customer satisfaction and product quality.

With its advantages in technological innovation, quality control, professional team, and customer service, Hopo has become a leader in the field of industrial mold manufacturing. In the future, Hopo will continue to focus on enhancing its core competitiveness, providing customers with higher-quality products and services, and jointly promoting the development and progress of industrial mold manufacturing.

Comments