Die Attach Machine Market 2024-2032:

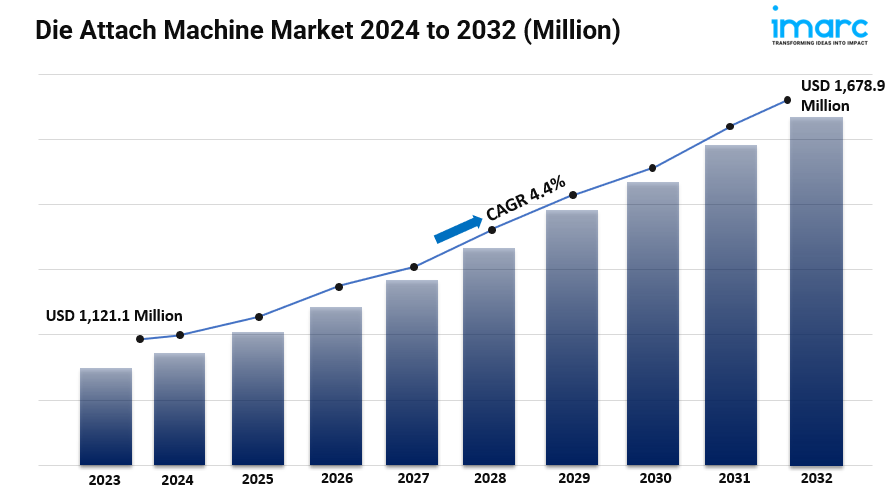

- The global die attach machine market size reached USD 1,121.1 Million in 2023.

- The market is expected to reach USD 1,678.9 Million by 2032, exhibiting a growth rate (CAGR) of 4.4% during 2024-2032.

- Asia Pacific leads the market, accounting for the largest die attach machine market share.

- Die bonder accounts for the majority of the market share in the type segment due to their high adoption across various industries, including consumer electronics and automotive.

- Epoxy holds the largest share in the die attach machine industry, owing to its versatility and widespread use in high-reliability products.

- LED represents the leading application segment, due to a surge in LED applications in automotive, consumer electronics, and lighting fuels.

- The increasing utilization of semiconductor devices is a primary driver of the die attach machine market.

- Technological advancements and the introduction of three-dimensional (3D) stacking, flip-chip, and wafer-level packaging (WLP)are reshaping the die attach machine market.

Request for a sample copy of this report: https://www.imarcgroup.com/die-attach-machine-market/requestsample

Industry Trends and Drivers:

- Increasing Demand for Semiconductor Devices:

The rising demand for semiconductor devices, driven by the growth of consumer electronics, automotive, and industrial sectors, is one of the major factors boosting the die attach machine market share. Moreover, rapid technological innovations such as fifth-generation (5G), artificial intelligence (AI), and the Internet of Things (IoT), creating the need for high-performance semiconductor components, are favoring the market growth. These technologies require advanced packaging solutions for efficient power management, high-speed performance, and miniaturization. Die-attach machines play a crucial role in the assembly process by ensuring accurate placement and strong bonding of semiconductor chips onto substrates or lead frames.

- Ongoing Shift Toward Advanced Packaging Technologies:

The introduction of advanced packaging technologies like three-dimensional (3D) stacking, flip-chip, and wafer-level packaging (WLP) due to their ability to enhance the performance, speed, and efficiency of semiconductor devices is catalyzing the die-attach machine market growth. These technologies require sophisticated die-attach machines to achieve precise placement and bonding, as well as handle a wide range of materials, including fragile or ultra-thin dies. Moreover, the growing focus of semiconductor companies on shifting toward smaller and more complex chip designs, paving the way for advanced die-attach machines with higher precision, flexibility, and speed, is contributing to the market growth.

- Growing Demand for Automation and Precision:

The increasing focus of the semiconductor manufacturing industry on automation and precision to meet the rising demands for miniaturized and high-performance devices is enhancing the die-attach machine size. These machines are equipped with advanced automation features, such as vision systems and real-time process monitoring, and are essential for ensuring accuracy and consistency in high-volume production environments. Moreover, the heightened ability of die-attach machines to maintain stringent tolerances while reducing human error and material wastage is stimulating the market growth. Additionally, the die attach machine market trends indicate that the growing need for precision die placement and bonding as devices become smaller and more complex is driving the market growth.

Die Attach Machine Market Report Segmentation:

Breakup By Type:

- Flip Chip Bonder

- Die Bonder

Die bonder account for the majority of shares due to their precision in attaching chips to substrates in semiconductor manufacturing.

Breakup By Technique:

- Epoxy

- Soft Solder

- Sintering

- Eutectic

- Others

Epoxy dominates the market as it offers strong adhesive properties and thermal stability.

Breakup By Application:

- RF and MEMS

- Optoelectronics

- Logic

- Memory

- CMOS Image Sensors

- LED

- Others

LED exhibits a clear dominance due to the growing demand for energy-efficient lighting and displays.

Breakup By Region:

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- North America (United States, Canada)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Argentina, Colombia, Chile, Peru, Others)

- Middle East and Africa ( Turkey, Saudi Arabia, Iran, United Arab Emirates, Others)

Asia Pacific holds the leading position owing to a large market for die attach machine driven by rising semiconductor manufacturing sector, strong industrial base, and growing demand for consumer electronics.

Top Die Attach Machine Market Leaders:

The die attach machine market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies.

Some of the key players in the market are:

- Anza Technology Inc.

- ASM Pacific Technology Limited

- Be Semiconductor Industries N.V.

- Dr. Tresky AG

- Fasford Technology Co Ltd. (Fuji Machinery Co., Ltd)

- Hybond Inc.

- Inseto UK Limited, Kulicke and Soffa Industries Inc.

- MicroAssembly Technologies Ltd.

- MRSI Systems (Mycronic AB (Publ))

- Palomar Technologies Inc.,

- Shinkawa Ltd. (Yamaha Motor Co. Ltd.)

Ask Analyst Browse full report with TOC List of Figures: https://www.imarcgroup.com/request?type=report&id=7423&flag=C

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services.

IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

Comments