In modern construction and industrial sectors, choosing the right materials is crucial for efficiency, durability, and long-term performance. One material that has gained widespread recognition is XLPE sheets. Known for their versatility, durability, and resistance to heat, chemicals, and moisture, XLPE sheets are transforming the way industries approach insulation, protection, and structural applications. This comprehensive guide explores everything you need to know about XLPE sheets in construction and industry, including their types, advantages, and applications.

What Are XLPE Sheets?

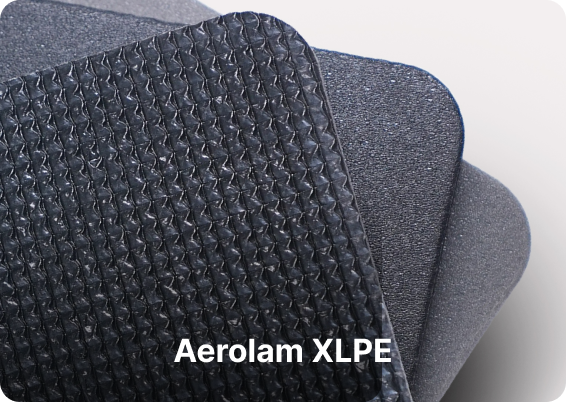

XLPE sheets are made from cross-linked polyethylene (XLPE), a polymer that undergoes a chemical cross-linking process to improve its mechanical strength, thermal stability, and chemical resistance. Unlike standard polyethylene, XLPE sheets can withstand high temperatures, heavy mechanical stress, and harsh environmental conditions.

The two primary types of XLPE sheets commonly used in construction and industry include:

- XLPE Insulation Sheets: Solid sheets primarily used for electrical and thermal insulation.

- XLPE Foam Sheets: Lightweight, cellular sheets designed for cushioning, impact absorption, and soundproofing.

Both types of sheets offer durability, chemical resistance, and adaptability, but they serve different purposes depending on the application.

Key Advantages of XLPE Sheets in Construction and Industry

1. Thermal and Electrical Insulation

XLPE insulation sheets provide excellent thermal resistance, making them ideal for high-temperature environments, including industrial machinery and electrical installations. Their dielectric properties also make them perfect for electrical insulation, protecting equipment and reducing the risk of electrical hazards.

2. Chemical and Moisture Resistance

Construction and industrial sites often involve exposure to chemicals, oils, and water. XLPE sheets are highly resistant to these elements, ensuring long-lasting performance without degradation. This makes them suitable for chemical storage, piping, and protective layers in harsh environments.

3. Lightweight Yet Durable

Despite their strength, XLPE sheets are lightweight, allowing for easy handling, installation, and transportation. Their mechanical durability ensures they can withstand heavy loads and physical stress, making them ideal for structural applications.

4. Shock Absorption and Cushioning

XLPE foam sheets, in particular, provide superior impact resistance and vibration damping, making them essential for protective packaging, machinery padding, and flooring in industrial environments.

5. Versatility and Customization

XLPE sheets can be cut, shaped, and laminated to meet specific project requirements. This flexibility allows them to be adapted for various industrial and construction applications.

Applications of XLPE Sheets in Construction

1. Thermal Insulation

XLPE insulation sheets are widely used for walls, roofs, and floors in commercial and residential buildings. Their thermal resistance helps reduce energy consumption by maintaining temperature control in HVAC systems and other building applications.

2. Soundproofing and Acoustic Control

XLPE foam sheets act as soundproofing layers, absorbing vibrations and reducing noise transmission in offices, apartments, and industrial facilities. This is particularly useful in high-noise environments such as factories and workshops.

3. Moisture and Chemical Protection

In construction, XLPE sheets are often used as protective barriers against moisture, water ingress, and chemical exposure. They can be installed under flooring, walls, or roofing to safeguard building materials from damage.

4. Vibration Damping

XLPE foam sheets provide cushioning for flooring and machinery, reducing vibrations and structural fatigue. This is essential for heavy-duty equipment and high-traffic areas in commercial buildings.

Applications of XLPE Sheets in Industry

1. Electrical and Electronics

Industries rely on XLPE insulation sheets for electrical panels, transformers, cables, and switchgear due to their excellent dielectric properties and thermal stability.

2. Automotive Manufacturing

XLPE foam sheets are used for seating, dashboards, interior padding, and NVH (Noise, Vibration, Harshness) control in vehicles. Insulation sheets protect wiring and engine components from heat and electrical hazards.

3. Industrial Machinery

XLPE sheets protect machinery from vibration, impact, heat, and chemical exposure, improving equipment longevity and reducing maintenance costs.

4. Packaging and Shipping

XLPE foam sheets are ideal for protective packaging of sensitive equipment, electronic components, and fragile materials. Their lightweight structure minimizes shipping costs while ensuring maximum protection.

5. Chemical and Heavy Industries

High-density XLPE sheets are used to construct chemical storage tanks, conveyor belts, protective barriers, and industrial flooring. Their chemical resistance ensures safety and durability in harsh environments.

Why Choose XLPE Sheet Company

When sourcing XLPE sheets for construction and industry, XLPE Sheet is a reliable provider offering:

- High-Quality Products: Manufactured with advanced cross-linking technology to ensure superior strength and thermal resistance.

- Wide Range of Options: From insulation to foam and high-density sheets, all variants are available to meet industry-specific needs.

- Custom Solutions: Sheets can be tailored in thickness, density, and size according to project requirements.

- Technical Support: Guidance for product selection, installation, and maintenance.

- Reliable Delivery: Ensures timely supply, reducing delays and ensuring project continuity.

Choosing XLPE Sheet guarantees access to premium-quality sheets that enhance operational efficiency, safety, and durability across construction and industrial applications.

How to Select the Right XLPE Sheet

Selecting the most suitable XLPE sheet involves several considerations:

- Determine the Application: Decide whether the sheet will be used for insulation, cushioning, vibration damping, or chemical protection.

- Consider Environmental Factors: Assess exposure to heat, chemicals, moisture, or mechanical stress.

- Choose Thickness and Density:

- Insulation sheets: Thicker sheets provide better thermal and electrical insulation.

- Foam sheets: Higher density offers superior impact absorption.

- Customization Requirements: Foam sheets are more adaptable for cutting, shaping, or laminating.

- Cost and ROI: Evaluate long-term benefits and maintenance savings against upfront investment.

By considering these factors, businesses can ensure optimal performance and durability for their specific application.

Maintenance and Longevity

XLPE sheets require minimal maintenance, but proper care extends their lifespan:

- Keep Clean: Remove dust, debris, and chemical residues.

- Protect from Sharp Objects: Prevent cuts or punctures, particularly in foam sheets.

- Store Properly: Keep sheets in a cool, dry environment.

- Regular Inspection: Check for wear or damage, especially in high-stress areas.

With proper maintenance, XLPE sheets can last for years, ensuring consistent performance and protection in both construction and industrial settings.

Conclusion

XLPE sheets have become an indispensable material in modern construction and industrial applications. Their thermal resistance, chemical stability, shock absorption, and versatility make them suitable for a wide range of uses, from insulation and soundproofing to protective packaging and machinery padding.

By partnering with XLPE Sheet, industries and construction projects gain access to high-quality, customizable sheets backed by expert support and reliable delivery. Whether for insulation, cushioning, vibration damping, or chemical protection, XLPE sheets provide long-lasting performance, enhanced safety, and improved operational efficiency.

Comments