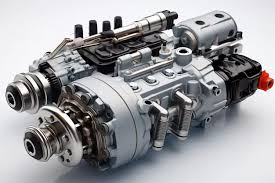

Engine control modules, or ECMs, are the central computers responsible for managing engine performance, fuel injection, ignition timing, and emission controls. When an ECM fails or malfunctions, engine performance can suffer, leading to misfires, poor fuel economy, or difficulty starting. Many vehicle owners and technicians explore options for used engine control module to restore reliable operation while keeping costs manageable. A used ECM can serve as an effective solution if properly tested and compatible with the vehicle’s make and model.

Purchasing a used engine control module requires careful consideration to ensure it functions correctly and matches the vehicle’s electronic systems. Modern ECMs store specific programming and data that must align with engine sensors and control parameters. Proper inspection and testing of the used module are essential to prevent further damage or operational issues. Understanding the benefits and limitations of a used ECM helps buyers make informed decisions that maintain engine performance.

In addition to affordability, used ECMs offer practical advantages for vehicles that have out-of-production parts or models where new ECMs are difficult to source. When acquired from reputable suppliers and tested for accuracy, used ECMs can reliably manage engine systems, restoring performance without the higher cost of brand-new components.

The Role of Engine Control Modules

How ECMs Function

The ECM collects data from various engine sensors, including airflow, temperature, and oxygen levels, to adjust fuel delivery and ignition timing. This ensures optimal combustion and efficient performance.

Impact on Engine Performance

A well-functioning ECM helps maintain smooth acceleration, proper idle, and fuel efficiency. Any malfunction can lead to stalling, rough running, or increased emissions.

Types of ECMs

ECMs can vary by vehicle make and model. Some are integrated with transmission control, while others focus solely on engine management. Compatibility is critical when selecting a used module.

Benefits of Choosing a Used ECM

Cost-Effective Replacement

Used ECMs provide a budget-friendly alternative to new units, making them a practical solution for older vehicles or high-mileage cars.

Quick Availability

Many used ECMs are readily available, reducing downtime compared to waiting for a new replacement or ordering from a manufacturer.

Environmentally Friendly

Reusing ECMs reduces electronic waste and the demand for new manufacturing, contributing to environmental sustainability.

How to Select a Used ECM

Verify Compatibility

Ensure the used ECM matches the vehicle’s make, model, engine type, and year. Mismatched ECMs may not communicate correctly with sensors or other electronic systems.

Check for Testing and Warranty

Choose suppliers who test ECMs for functionality and provide a warranty. This reduces the risk of receiving a defective module and provides peace of mind.

Review Programming Requirements

Some ECMs require reprogramming or flashing to match the vehicle’s VIN and settings. Confirm that the used ECM can be correctly programmed before purchase.

Installation Considerations

Professional Installation

Correct installation ensures proper communication between the ECM and engine sensors. Professional installation helps prevent electrical faults or misconfigurations.

Sensor Check

Before installing a used ECM, verify that engine sensors are functioning correctly. Faulty sensors may cause the new module to misinterpret data and operate incorrectly.

Firmware Updates

Some used ECMs may require software updates to function properly with the vehicle’s system. Confirm update requirements with the supplier or a certified technician.

Maintenance Tips for ECM Longevity

Protect From Moisture and Heat

Excessive heat or water exposure can damage ECM components. Keep the module in a secure, ventilated location and ensure engine bay protection.

Avoid Jump-Starting Issues

Incorrectly jump-starting a vehicle can damage the ECM. Always follow proper procedures to prevent electrical surges.

Regular Diagnostic Checks

Periodically scanning the ECM for fault codes ensures it continues to operate correctly and helps identify potential problems early.

Advantages of Using a Tested ECM

Restored Engine Reliability

A functioning ECM ensures smooth operation, proper fuel management, and reliable ignition timing, reducing engine performance issues.

Reduced Repair Costs

Used ECMs provide a cost-efficient solution to replace malfunctioning units without the higher expense of new parts.

Extended Vehicle Life

Replacing a faulty ECM with a tested used module can prolong the usable life of older vehicles and prevent unnecessary engine damage.

Quick and Convenient Solution

Sourcing a tested used ECM is often faster than waiting for a new replacement, especially for out-of-production models.

Frequently Asked Questions

Can a used engine control module work as well as a new one?

Yes, a properly tested and compatible used ECM can perform reliably and manage engine functions effectively.

Do used ECMs require programming?

Many do. Some modules need to be flashed or programmed to match the vehicle’s VIN and sensor configurations for proper operation.

What are the signs of a failing ECM?

Symptoms include rough idling, misfires, engine stalling, poor fuel efficiency, and check engine lights. Early detection allows timely replacement.

How can I ensure a used ECM is reliable?

Purchase from reputable suppliers who test the ECM for functionality, offer warranties, and verify compatibility with your vehicle.

Is professional installation necessary for a used ECM?

Professional installation is recommended to ensure proper communication with engine sensors and to prevent electrical issues or programming errors.

Comments