Introduction

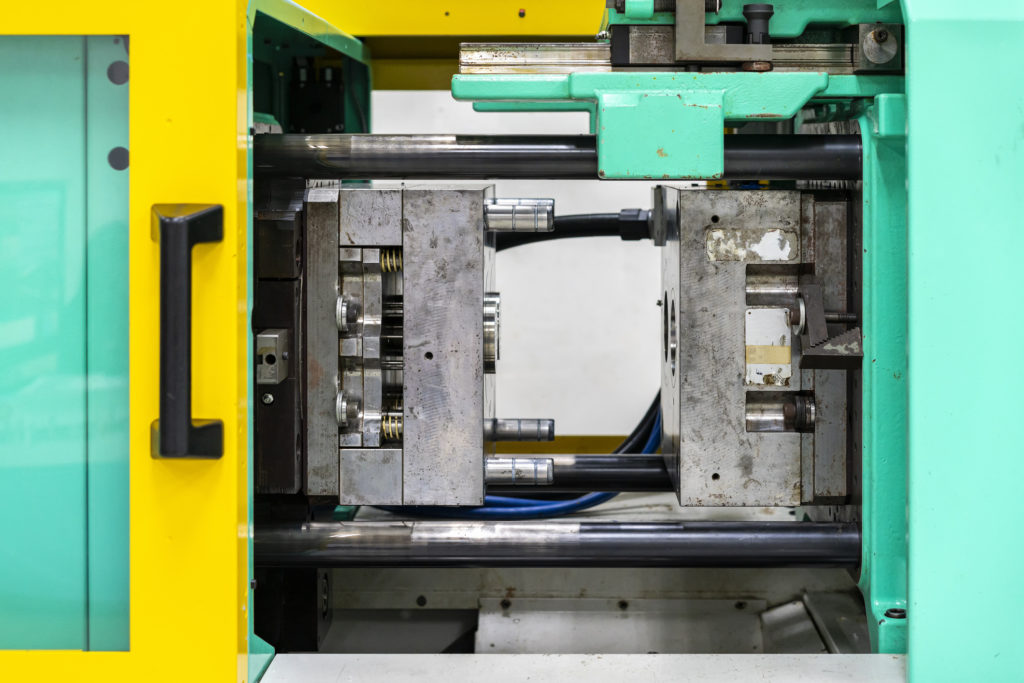

As Africa Injection Molding Machine Market sector seeks innovation to increase food production, reduce post-harvest losses, and empower smallholder farmers, a new player is entering the field: injection molding technology. Once mainly associated with consumer goods and packaging, injection molding is now a key enabler for agritech startups across Africa. These companies are using affordable, durable plastic components to modernize traditional farming practices and solve logistical and environmental challenges.

This article explores how African startups are leveraging the Africa injection molding machine market to design and produce agricultural solutions, boosting productivity, sustainability, and profitability across the continent.

Why Plastics Are Vital to Agricultural Innovation in Africa

Plastics offer a range of benefits for agriculture:

· Lightweight and easy to transport

· Resistant to corrosion and environmental damage

· Affordable to mass-produce

· Customizable to specific farm tasks

Injection molding machines allow for high-volume production of uniform plastic parts that are essential for:

· Irrigation systems

· Seedling trays

· Storage containers

· Poultry and livestock equipment

· Farming tools and accessories

As the demand for these products grows, African startups are filling the gap with locally designed, molded solutions.

Key Drivers Behind the Injection Molding Boom in Agriculture

1. Growing Population and Food Demand

Africa’s population is expected to reach 2.5 billion by 2050, putting pressure on food systems. Precision farming tools, irrigation kits, and crop handling equipment are becoming indispensable—all of which rely on plastic components.

2. Youth-Led Agritech Startups

With over 60% of Africa’s population under 25, young entrepreneurs are entering the agricultural space armed with tech and design skills. Injection molding helps these startups bring their product ideas to life at scale.

3. Push for Mechanization and Modernization

Governments and NGOs are investing in agricultural transformation initiatives. As a result, demand is rising for affordable, scalable plastic-based farming equipment.

4. AfCFTA and Local Manufacturing Trends

The African Continental Free Trade Area (AfCFTA) promotes local manufacturing and intra-African trade. Injection molding machines and tools are increasingly sourced and used locally to reduce reliance on imports.

Products Modernizing Farming Through Injection Molding

1. Drip Irrigation Components

· Emitters, connectors, pipes, and junctions are molded to precise dimensions

· Customization based on local water pressure and crop types

2. Seedling Trays and Nursery Pots

· Reusable and designed for optimal root aeration

· Molded to accommodate different seed types and growing conditions

3. Livestock Feeding Equipment

· Molded plastic feeders, drinkers, and troughs are durable and hygienic

· Easier to clean and relocate than metal alternatives

4. Pesticide and Fertilizer Sprayers

· Lightweight and ergonomic sprayer bodies are molded for ease of use

· Made from chemical-resistant plastic blends

5. Post-Harvest Storage Solutions

· Crates and bins reduce damage and spoilage during transportation

· Molded to nest for efficient storage and handling

Challenges Facing Local Injection Molders and Startups

Despite the opportunities, several hurdles remain:

· Limited Access to High-Quality Molding Machines: Many startups rely on imported second-hand machines, which may lack precision.

· Design-to-Tooling Gap: Startups often struggle with converting CAD designs into cost-effective molds.

· Financing: Mold tooling is expensive, often out of reach for early-stage startups.

· Raw Material Supply: High cost and inconsistent availability of virgin and recycled plastics.

To address these issues, partnerships with universities, government grants, and shared mold making facilities are being promoted.

Regional Highlights: Where Injection Molding for Ag Is Taking Off

· Kenya: Nairobi and Eldoret are becoming agri-industrial zones with local mold shops producing irrigation and greenhouse parts.

· Nigeria: Lagos and Kano see increased injection molding of plastic sprayers and storage bins for use in northern farm belts.

· Ethiopia: With state support for industrialization, plastic parts for farm mechanization are being molded in Addis Ababa.

· South Africa: Home to well-established mold makers supporting both commercial farms and agritech startups.

· Uganda: NGOs are distributing plastic farm kits molded locally to boost productivity in rural communities.

The Role of Policy and Partnerships

Governments and organizations are recognizing the role of injection molding in agricultural development. Initiatives include:

· Incentives for local mold and machine manufacturing

· Tech hubs focused on agritech and product prototyping

· Financing schemes for farm equipment startups

International NGOs like the Bill & Melinda Gates Foundation and USAID are also funding innovation in farm tools, many of which are made using injection molding.

The Future: Toward Scalable, Sustainable Agri-Plastics

To meet climate goals and ensure long-term viability, startups are exploring:

· Bioplastics and compostable polymers for trays and containers

· Closed-loop recycling systems within rural cooperatives

· Designs for disassembly to enhance reuse and reduce waste

Digital twin technology and AI-driven mold design are expected to further streamline production, reduce cost, and expand access.

Conclusion

Injection molding is proving to be a game-changer for African agriculture, enabling the rapid production of cost-effective, durable, and scalable tools and components. Startups across the continent are harnessing this technology to empower farmers, reduce food waste, and increase yields.

As access to molding machines, design expertise, and materials improves, expect to see even more innovative agricultural products made in Africa, for Africa.

Comments