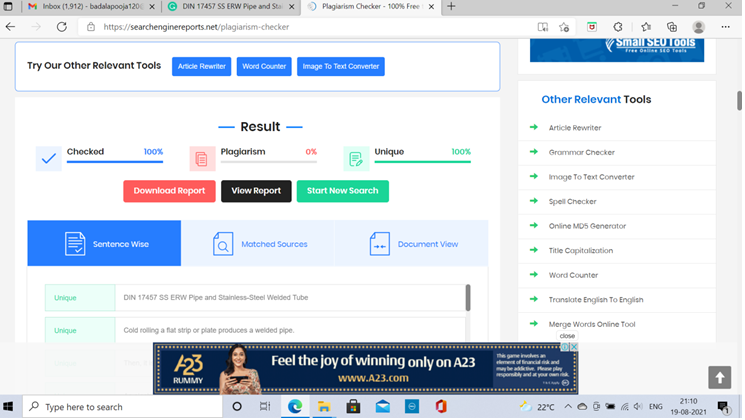

Cold rolling a flat strip or plate produces a welded pipe. Then, it is longitudinally welded to form a cylinder shape. An electric resistance weld is used to create the SS ERW Pipe DIN 17457 SS. When the stainless-steel strip is passed via an electric current, it melts even further the joints that unite the pipes. High- and low-temperature applications are covered by these Stainless-Steel Welded tubes. Stainless Steel Welded Pipe Manufacturers in India focus on creating high-quality products at affordable prices.

AISI 304LN/304h Pipe and ASTM A312 TP304 Seamless/ Welded Tube

There are two major elements of an austenitic alloy, which are nickel and chrome. Corrosion and severe temperatures are not a problem for the 304 Stainless Steel Pipe. Pipes made from these materials are also strong and durable, with good yield and tensile strength. They are the most often used stainless steel pipes in the world. Stainless Steel 304 pipe has exceptional machinability and welding capabilities, to name a few. These 304 alloysare commonly utilized as a structural material in the food, chemical, and architectural industries.

screenshot_2.png

ASTM A210 Heat Exchanger Tube and SA210 A1 Condenser

Boiler class applications employ ASME SA210 Grade A1 Boiler Tube and Grade C Tubing. Among the components of grade A1 are carbon, manganese, silicon, phosphorus, and sulfur. Strong, abrasion-resistant, and low-cost, this carbon steel is a good choice. There is a minor improvement in mechanical qualities and chemical composition with the grade C. In terms of minimum tensile strength, the ASTM A210 Grade A1 Boiler Pipe has 415 MPa, 255 MPa, and a 30 percent elongation rate. Duplex 2205 Pipe, often known as the standard duplex grades, is the most commonly used duplex.

ASTM B444 UNS N06625 Seamless Tube & Nickel Alloy Inconel 625 Pipe

Niobium Alloy 625 Tubing is composed of nickel, chromium, and iron with a molybdenum and cobalt content of 10 percent and copper, aluminum, and titanium with phosphorus and boron content of 5 percent. The UNS N06625 Tube has extreme corrosion resistance due to the material composition. Acids and alkalis do not affect this substance. Various technologies are used to create the pipes, including seamless, ERW, EFW, welding, and fabrication. The seamless pipes are the most exact in terms of dimension. As a result, the material has a higher strength than most other materials. The minimum Tensile Strength of the Inconel 625 Pipe is 930 MPa.

screenshot_1.png

ST 52.3 Seamless Pipe and EN 1.0570 ST52 Precision Steel Tube

Low-carbon steel is used to make ST 52 Carbon Steel Seamless Tubes, which have good strength values and limited corrosion resistance. They are primarily used in oil and gas production as well as in petrochemical and petroleum-related industrial applications. There are three types of DIN 2391 ST 52 Seamless Pipe: seamless, welded, and ERW. Each has slightly different mechanical qualities. Carbon, silicon, manganese, phosphorus, and sulfur concentration determine the chemical characteristics. The material's minimum yield strength is 520 MPa, while its minimum tensile strength is 600 MPa. The DIN 2391 ST 52 Pipe can be drawn, expanded, and subjected to various forming and machining operations as a precision pipe.

Comments