CNC manufacturing, or computer numerical control manufacturing, is a process used to create parts and products by using computer-controlled machines. This technology has revolutionized manufacturing by providing greater accuracy, efficiency, and speed. Here's an overview of CNC manufacturing and how it works.

CNC Manufacturing Process

The CNC manufacturing process involves the use of computer-controlled machines, such as lathes, mills, routers, and plasma cutters, to create precise parts and products. The process typically involves the following steps:

Design: The first step in the CNC Manufacturing process is designing the part or product using computer-aided design (CAD) software. This software allows designers to create a digital model of the part or product, including its dimensions and specifications.

Programming: Once the design is complete, the CAD file is converted into a CNC program that the machine can understand. This involves using computer-aided manufacturing (CAM) software to generate a toolpath that the machine will follow to create the part or product.

Setup: The machine is then set up to produce the part or product. This involves loading the CNC program, positioning the workpiece, and setting the machine parameters.

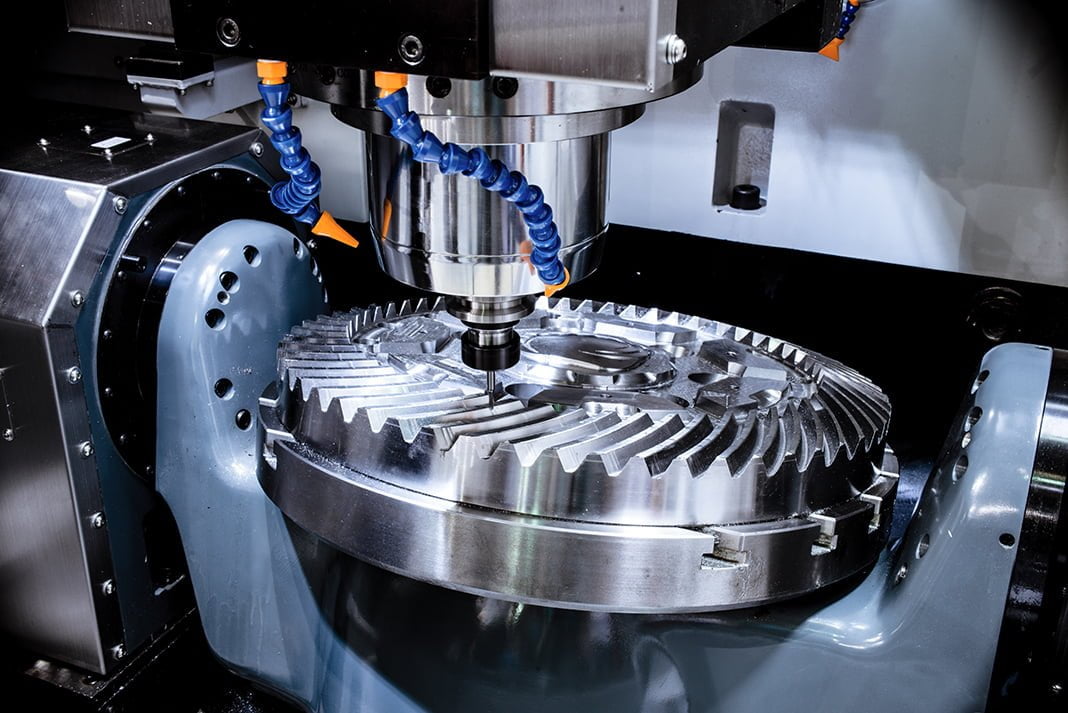

Machining: The machine then performs the machining operations according to the programmed toolpath. This typically involves cutting, drilling, or shaping the workpiece using a variety of tools.

Inspection: Once the machining is complete, the part or product is inspected to ensure that it meets the required specifications.

Benefits of CNC Manufacturing

Cnc Machining USA offers several benefits over traditional manufacturing methods, including:

Greater accuracy: CNC machines can produce parts and products with a high degree of accuracy and precision, which is critical in many industries.

Increased efficiency: CNC machines can work continuously and at high speeds, which can increase productivity and reduce lead times.

Cost-effectiveness: CNC manufacturing can be cost-effective, especially for large-scale production runs, as it reduces labor costs and minimizes material waste.

Flexibility: CNC machines can be programmed to produce a wide range of parts and products, making them a versatile manufacturing solution.

Applications of CNC Manufacturing

CNC manufacturing is used in a variety of industries, including:

Aerospace: CNC manufacturing is used to create precision parts for aircraft, satellites, and other aerospace applications.

Automotive: CNC manufacturing is used to produce engine parts, transmissions, and other automotive components.

Medical: CNC manufacturing is used to create medical implants, prosthetics, and other medical devices.

Consumer products: CNC manufacturing is used to produce a wide range of consumer products, including electronics, furniture, and toys.

By using CNC manufacturing, companies can produce high-quality, precise parts and products at a faster rate and lower cost, making it an essential process in today's manufacturing industry.

Click Here For More Information:-

Comments