Platform gratings are essential structural components in industrial, construction, and architectural applications. They provide strong, durable surfaces that allow for drainage, ventilation, and safe passage. Among the most critical aspects of platform grating selection is steel grating thickness, which directly impacts load capacity, durability, and safety.

This article will explore the standard sizes for platform gratings, with a focus on steel grating thickness, industry standards, applications, and factors to consider when choosing the right grating for your needs.

What Does “Standard Platform Grating” Mean?

The term “standard platform grating” refers to a commonly accepted range of dimensions and specifications used for safety platforms, walkways, catwalks, and industrial floors. These dimensions vary based on:

- Material type (steel, aluminum, stainless steel, fiberglass)

- Load requirements

- Span length

- Environmental conditions

While there is no single “global” standard, many industries adopt specifications outlined by recognized bodies such as:

- ANSI/NAAMM MBG 531 (USA)

- BS 4592 (UK)

- AS 1657 (Australia)

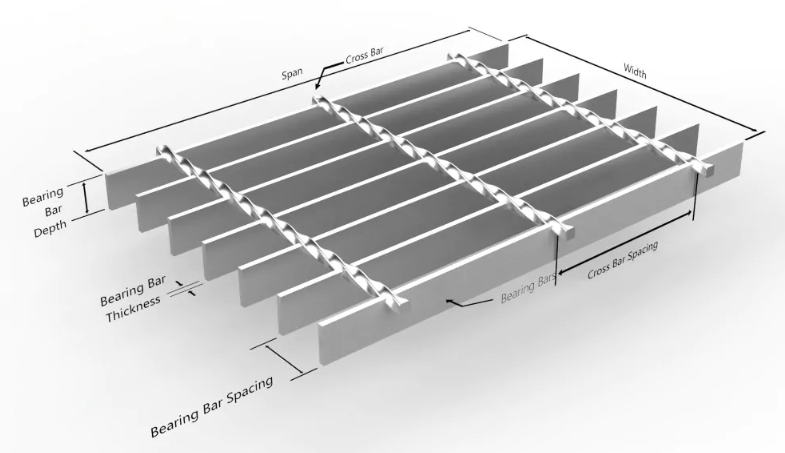

In most industrial contexts, platform grating specifications are defined by bearing bar spacing, steel grating thickness, and overall panel size.

How Does Steel Grating Thickness Affect Performance?

The steel grating thickness—the measurement of the bearing bars’ vertical dimension—directly influences the grating’s ability to bear weight. Thicker gratings can withstand heavier loads but also increase weight and cost.

Key effects of steel grating thickness:

- Load Bearing Capacity – Thicker steel bars can handle higher static and dynamic loads.

- Deflection Resistance – Increased thickness minimizes deflection under heavy loads, maintaining safety.

- Durability – More thickness means longer service life in high-traffic areas.

- Corrosion Protection – Galvanized coatings on thicker steel last longer in harsh environments.

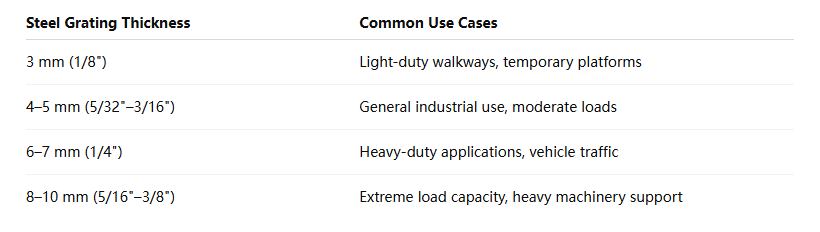

What Are the Common Steel Grating Thickness Options?

Steel grating thickness is usually expressed in millimeters or inches, referring to the depth of the bearing bars.

Typical options include:

Note: The choice of steel grating thickness should always align with span length and load requirements.

What Is the Standard Size for Platform Grating Panels?

While the steel grating thickness is a critical parameter, overall panel dimensions also matter. Standard panel sizes often include:

- Width: 600 mm, 750 mm, 1000 mm

- Length: 1000 mm to 6000 mm (varies by supplier)

- Bearing Bar Spacing: Commonly 30 mm or 40 mm center-to-center

- Cross Bar Spacing: Usually 50 mm to 100 mm

In the United States, a common standard is 1" x 3/16" bars with 4" cross bars.

How to Determine the Right Steel Grating Thickness for Your Application?

When selecting steel grating thickness, consider:

Load Type:

- Pedestrian traffic

- Vehicle traffic

- Machinery placement

Span Length:

- Longer spans require thicker gratings to prevent deflection.

Safety Requirements:

- Anti-slip surfaces and reinforced edges may influence thickness choice.

Environment:

- Corrosive or wet environments may require stainless steel or thicker galvanized coatings.

Example: A 6 mm thick galvanized steel grating may be ideal for heavy-duty catwalks in a manufacturing plant.

Why Is Steel Grating Thickness Critical for Safety Compliance?

Safety regulations often specify minimum steel grating thickness to ensure stability and prevent accidents.

For example:

- In offshore oil platforms, thick gratings (≥6 mm) are often mandatory due to high load and corrosion risk.

- In public spaces, regulations may require anti-slip serrated bars, adding to thickness.

Choosing insufficient thickness can result in:

- Excessive flexing under load

- Early wear and deformation

- Safety hazards from broken bars

Are There Industry Standards for Steel Grating Thickness?

Yes. While specifics vary by country, most standards recommend thickness ranges for given spans and loads. For instance:

- ANSI/NAAMM MBG 531: Suggests minimum bar depths for given spans and loads.

- BS 4592: Specifies bar depth and spacing requirements.

These standards are essential for engineers and safety officers when specifying materials.

Can Platform Gratings Be Customized Beyond Standard Sizes?

Absolutely. While standard panel sizes and thicknesses are common for cost efficiency, custom fabrication allows for:

- Unique steel grating thickness to suit special loads

- Non-standard panel shapes (curved, cutouts for pipes)

- Additional surface treatments (painting, powder coating)

For example, Huijin metal meshes provides customized gratings for both industrial and architectural applications, including platforms with unique designs.

What Role Does Steel Grating Thickness Play in Architectural Applications?

In architecture, gratings are used for:

- Decorative facades

- Stair treads

- Sunshades

- Floor panels in open public areas

Here, steel grating thickness still matters—thicker gratings offer a more pronounced visual profile and greater durability.

How to Maintain Platform Gratings for Long Service Life?

Maintenance tips:

- Regular Cleaning: Prevents buildup of debris that may cause corrosion.

- Inspection: Look for bent bars or cracks in welds, especially on thinner gratings.

- Surface Treatment: Re-galvanize or repaint as needed.

Thicker gratings typically require less frequent maintenance due to higher resistance to damage.

Conclusion

The steel grating thickness is one of the most important specifications in determining platform grating performance. While standard sizes provide a cost-effective starting point, the right choice depends on load, span, environment, and safety requirements. Whether for industrial platforms or architectural features, understanding these parameters ensures safe, durable, and efficient installations.

Comments