In the realm of industrial engineering and manufacturing, the integrity of machinery and pipelines is paramount. Vital components such as gaskets play a pivotal role in ensuring that these systems operate smoothly and efficiently. Among the diverse array of gasket types available, Metal Jacked Gaskets stand out as a testament to durability, resilience, and versatility in demanding environments.

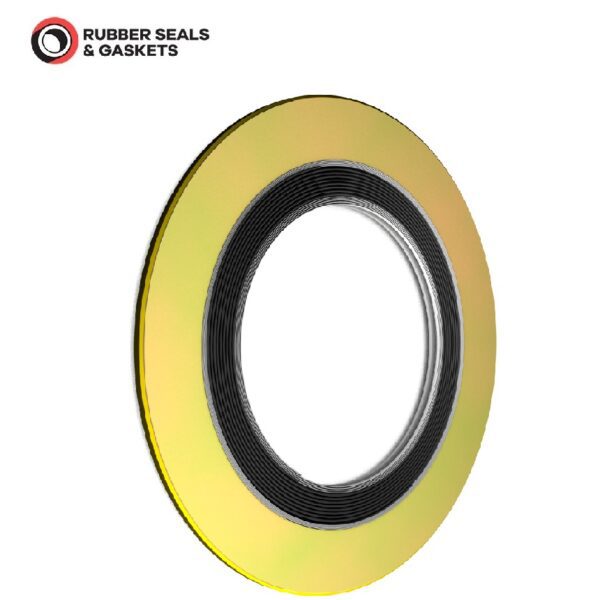

Metal jacketed gaskets are engineered to withstand extreme temperatures, pressures, and corrosive substances, making them indispensable in various industries such as oil and gas, chemical processing, power generation, and more. Unlike traditional gaskets made solely of rubber or fiber materials, metal jacketed gaskets feature a robust metal casing that encases a soft filler material, typically graphite, PTFE (polytetrafluoroethylene), or non-asbestos materials.

The unique construction of metal jacketed gaskets combines the flexibility of the filler material with the strength and stability of the metal casing, resulting in a sealing solution that can endure the harshest operating conditions. The metal jacket provides rigidity and prevents over-compression, ensuring a reliable seal even under high bolt loads and fluctuations in temperature and pressure.

One of the key advantages of metal jacketed gaskets is their adaptability to various flange configurations and surface finishes. The metal casing can be manufactured from different materials such as stainless steel, carbon steel, or exotic alloys, allowing engineers to select the appropriate material based on the specific requirements of the application. Additionally, the filler material can be tailored to enhance chemical compatibility and resistance to aggressive fluids, acids, and gases encountered in industrial processes.

Metal jacketed gaskets are renowned for their ability to maintain a tight and leak-free seal over prolonged periods, minimizing the risk of costly downtime, environmental hazards, and safety concerns. Their resilience to compression set and relaxation ensures consistent performance, making them ideal for critical sealing applications where reliability is non-negotiable.

In addition to their superior sealing capabilities, Metallic Gaskets gaskets offer ease of installation and removal, facilitating maintenance and repair activities. The metal casing provides structural support during handling and installation, reducing the likelihood of damage or deformation compared to softer gasket materials. Furthermore, their reusability and long service life contribute to cost savings over time, making them a cost-effective solution for demanding industrial environments.

Metal jacketed gaskets find widespread use in a myriad of applications, including valve bonnets, heat exchangers, pressure vessels, flanged connections, and exhaust systems. Their versatility and performance make them indispensable across diverse industries where safety, reliability, and regulatory compliance are paramount concerns.

Comments