Introduction

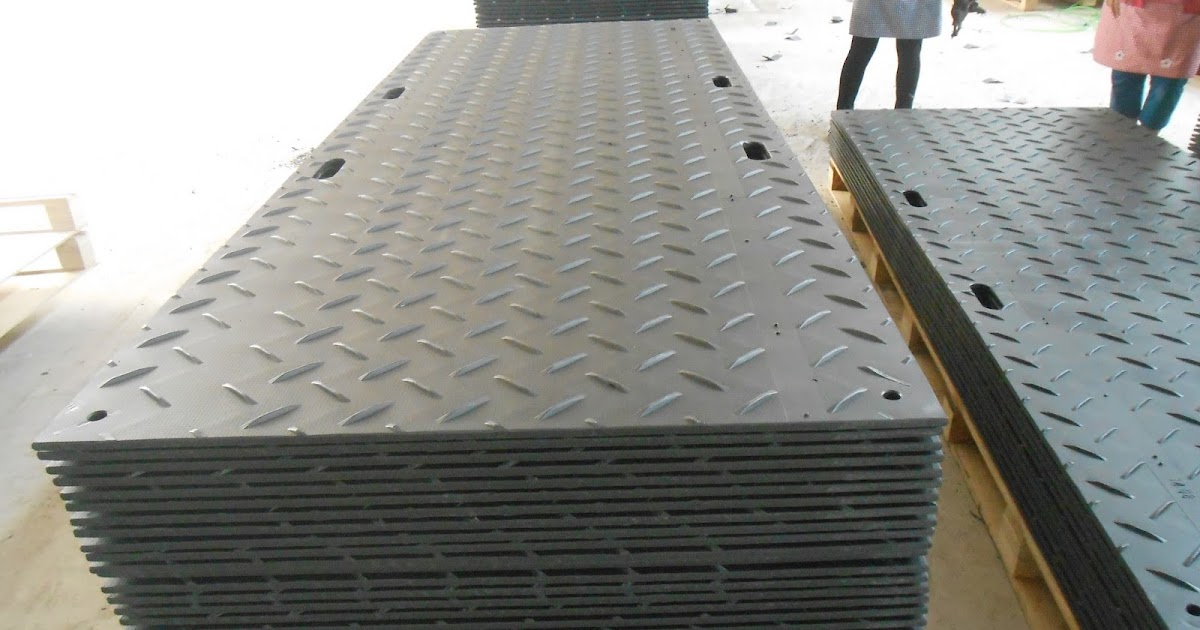

Ultra-High Molecular Weight Polyethylene UHMWPE Pad are revolutionizing various industrial sectors with their superior properties and versatility. These pads offer exceptional durability and resistance to wear, making them ideal for numerous applications. This blog explores the benefits, uses, and maintenance tips for UHMWPE pads, ensuring your operations run smoothly and efficiently.

What is UHMWPE and Why is It Beneficial?

Understanding the Material

UHMWPE stands for Ultra-High Molecular Weight Polyethylene, a type of thermoplastic that boasts incredible strength and durability. Its high resistance to abrasion, impact, and chemicals makes it a preferred material in many industrial applications. UHMWPE pads are not only strong but also lightweight, which eases handling and installation processes.

Key Benefits of UHMWPE Pads

The primary advantage of UHMWPE pads is their longevity. These pads endure extreme conditions without degrading, making them a cost-effective solution for long-term usage. Additionally, their low friction coefficient reduces wear on both the pads and the equipment they interact with, which further enhances their value in industrial settings.

Common Applications of UHMWPE Pads

Use in Heavy Machinery

UHMWPE pads are extensively used as support blocks in heavy machinery. Their ability to absorb shock and reduce vibration protects machinery components, leading to extended machinery life and reduced maintenance costs.

Role in Transportation and Handling

In the transportation sector, UHMWPE pads are used to facilitate the smooth movement of goods. They are particularly valuable in material handling systems, where their low friction helps in the efficient transfer and movement of heavy loads.

Installation Tips for UHMWPE Pads

Preparing the Installation Surface

Proper installation is crucial for maximizing the effectiveness of UHMWPE pads. The surface where the pad will be installed must be clean and smooth to ensure optimal performance. Any debris or irregularities can reduce the pad's efficacy and shorten its lifespan.

Securing the Pads Properly

It is important to use appropriate fasteners and adhesives that are compatible with UHMWPE to secure the pads in place. Ensuring that the pads are evenly supported and correctly aligned prevents premature wear and tear.

Maintenance and Care for UHMWPE Pads

Regular Inspections

Regularly inspect UHMWPE pads for any signs of wear or damage. Early detection of issues can prevent more serious problems down the line and keep your operations running smoothly.

Cleaning Procedures

Keeping UHMWPE pads clean will extend their service life. They can be easily cleaned with standard cleaning agents, but it's important to avoid abrasive materials that could scratch the surface.

Future Prospects of UHMWPE Pads in Industry

Technological Advancements

With continuous advancements in polymer technology, UHMWPE pads are expected to see improvements in their performance and applications. These enhancements will further boost their efficiency and suitability for even more demanding environments.

Expanding Market Reach

As industries become more aware of the benefits of UHMWPE pads, their usage is set to increase across different sectors. This expansion is predicted to drive further innovations and applications, making UHMWPE pads a staple in industrial applications worldwide.

Comments