Air Conveyor Systems: The Efficient Solution for Lightweight Product Handling

Learn how air conveyor systems deliver fast, gentle, and cost-effective transportation for bottles, cans, and lightweight products.

Intro:

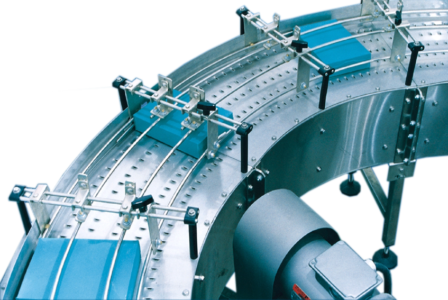

For high-speed production lines handling lightweight containers, traditional conveyor belts can cause friction, scuffing, and inefficiencies. Air conveyor systems use a controlled stream of air to float products along a track, reducing contact and enabling smoother, faster movement.

Why Choose Air Conveyor Systems:

- Gentle Handling: No scuffing or surface damage.

- High Throughput: Maintains consistent product flow at high speeds.

- Energy Efficiency: Uses air pressure instead of motor-driven belts for movement.

How They Work:

Air conveyor systems channel compressed or ambient air through precision-engineered ducts. This air pressure lifts and propels containers—such as PET bottles or aluminum cans—along the conveyor path, keeping them upright and stable.

Advantages Over Traditional Conveyors:

- Lower Maintenance: Fewer moving parts mean less wear and tear.

- Space Savings: Lightweight design allows flexible layouts.

- Reduced Product Waste: Gentle movement prevents damage during transit.

Industries Using Air Conveyor Systems:

Beverage bottling, food processing, pharmaceutical packaging, and cosmetic manufacturing.

Conclusion:

capping systems are a modern, reliable solution for transporting lightweight products at speed. They keep production lines running efficiently while protecting your product integrity—making them a smart choice for competitive manufacturing environments.

Source Url : - https://sites.google.com/view/dillin-7/home

Comments