Versatility in Design and Application

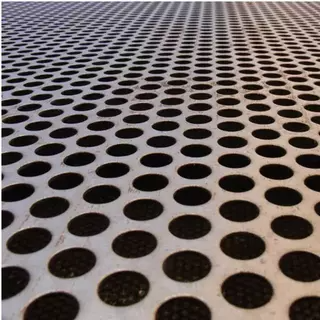

Aluminium perforated sheets are created by punching a series of holes, slots, or other shapes into a sheet of aluminium. This process allows for a vast range of designs, patterns, and sizes, catering to different needs and preferences. The versatility in design is one of the key reasons for their widespread use.

Architectural Applications: One of the most prominent uses of aluminium perforated sheets is in architecture. They are often used for building facades, sunshades, and interior design elements. The perforations allow for natural light and ventilation while providing a modern and sleek appearance. Aluminium Perforated Sheet Architects and designers appreciate the flexibility in creating custom patterns that enhance the aesthetic value of buildings.

Industrial Applications: In the industrial sector, aluminium perforated sheets are used for filtration, ventilation, and safety applications. They are commonly found in machinery guards, air diffusers, and speaker grilles. The perforations allow for effective airflow and sound diffusion while maintaining structural integrity.

Automotive and Aerospace Industries: Aluminium perforated sheets are also utilized in the automotive and aerospace industries. In these sectors, lightweight materials are crucial for improving fuel efficiency and performance. Perforated sheets are used in components like grilles, heat shields, and interior trim, where they provide a combination of strength and weight reduction.

Benefits of Aluminium Perforated Sheets

Lightweight and Durable: Aluminium is known for its excellent strength-to-weight ratio. Perforated sheets maintain this property, making them ideal for applications where weight reduction is essential without compromising on durability. This is particularly important in industries like automotive and aerospace, where every gram counts.

Corrosion Resistance: Aluminium naturally forms a protective oxide layer that prevents corrosion. This makes perforated aluminium sheets suitable for outdoor and marine applications, where exposure to moisture and harsh environments is common. The corrosion resistance ensures longevity and reduces maintenance costs.

Aesthetic Appeal: The ability to create intricate patterns and designs with perforated sheets adds a unique visual appeal to any project. Whether used in architectural facades or interior design elements, the modern and sophisticated look of perforated aluminium can enhance the overall aesthetics.

Energy Efficiency: In architectural applications, perforated sheets can contribute to energy efficiency. When used as sunshades or screens, they help regulate the amount of sunlight entering a building, reducing the need for artificial lighting and air conditioning. This can lead to significant energy savings and a more sustainable building design.

Acoustic Control: Perforated aluminium sheets are effective in controlling sound levels. They are used in acoustic panels and soundproofing applications to diffuse sound waves and reduce noise levels. This is particularly beneficial in environments like offices, auditoriums, and recording studios.

Common Uses of Aluminium Perforated Sheets

Interior Design: Perforated sheets are used in interior design for creating partitions, ceiling tiles, and decorative panels. Their aesthetic appeal and ability to allow light and air through make them a popular choice for modern interiors.

Safety and Security: In industries where safety is a priority, perforated sheets are used for machine guards, protective barriers, and fencing. Stainless Steel Perforated Sheet The perforations provide visibility and ventilation while ensuring safety.

Ventilation and Filtration: Perforated sheets are widely used in HVAC systems for ventilation and filtration purposes. They allow for efficient airflow while preventing the entry of debris and contaminants.

Comments