Carbon steel is made up of carbon and iron which is more durable and resistant to stress. These characteristics allow the pipes to be used in heavy-duty applications produced by Carbon Steel Pipe Manufacturers in India.

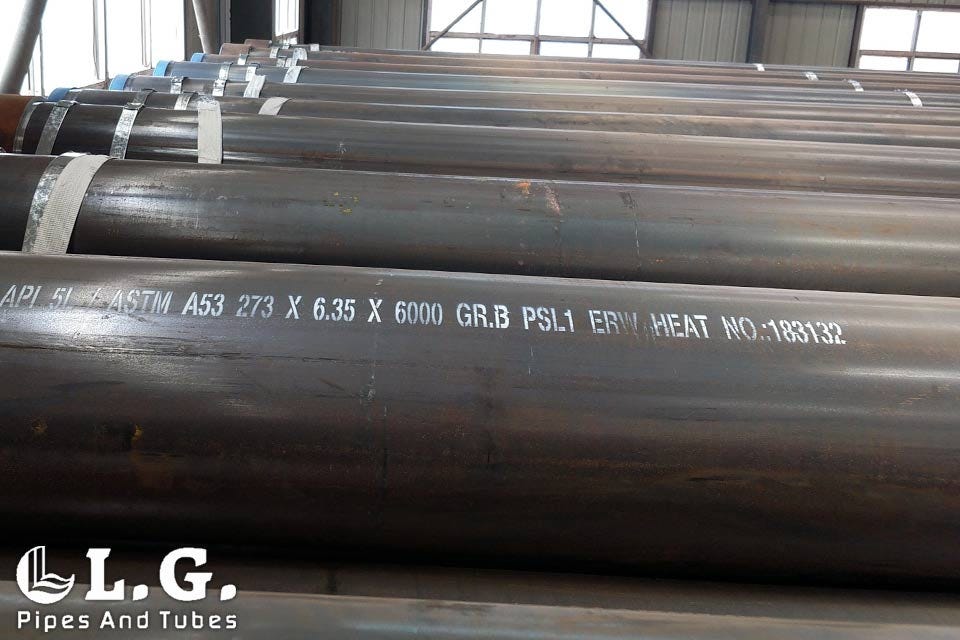

There are various production processes and types. Long carbon steel sheets are welded into pipes to make carbon steel welded pipe. Electric resistance welded Carbon Steel ERW Pipe is also available, contributing to overall strength. Different mechanical qualities exist, such as pressure containment, controlled by the pipe schedules.

What is ASTM A106 Grade B Pipe Specification?

The ASTM A106 Gr B Pipe standard specification for seamless carbon steel pipe used in high-temperature applications is ASTM A106/ASME SA106. It comes in three grades: A, B, and C, with A106 Grade B being the most frequent. It is employed in various industries, including pipeline systems for oil and gas, water, and mineral slurry transportation, as well as boilers, construction, and structural applications.

On chemical position and mechanical qualities, ASTM A106 Grade B pipe is equal to ASTM A53 Grade B and API 5L B pipe, in general use carbon steel and yield strength.

What are stainless steel plates?

Alloy 317L has stronger creep, stress-to-rupture, and tensile strength at increasing temperatures than ordinary stainless steel. There are many 317l stainless steel pipe manufacturers in India, among which you can choose. It’s an “L” grade with a low carbon content that resists sensitization during welding and other thermal processes.

The high quantities of these elements make the alloy more resistant to chloride pitting and general corrosion than the traditional 304/304L and 316/316L grades. In severely corrosive settings containing sulfurous media, chlorides, and other halides, the alloy provides better resistance than 316L.

Specification for A333 Grade 6 Pipe

Carbon, max 0.30, Phosphorus, max 0.025, Sulfur, max 0.025, and Manganese, 0.29–1.06 make up the chemical composition of LTCS ASTM A333 gr 6 pipe. The ASTM A53 Gr B Pipe minimum impact test temperature for SA333 Gr. 6 Seamless Pipe is -50 F. (-45 C). ASTM A333 Grade 6 pipe must have a minimum Yield Strength of 35,000 psi (240 MPa), a minimum Elongation of 2 in. or 50 mm (or 4D), and a minimum Tensile Strength of 60,000 psi (415 MPa).

Carbon steel pipes

The ASTM A333 Grade 6 Pipe is made when carbon is added to iron. According to a recent study, carbon is the ideal addition for any ferrous material. However, suitable alloying components can be found in piping products. Manganese is 1.65 percent, copper is 0.60 percent, and silicon is 0.60 percent in carbon pipes. For most construction projects, pipe pile suppliers prefer carbon steel pipe. It is strong and long-lasting. It is, nevertheless, more expensive than any other pipe kind.

Final thoughts

Chromium, manganese, nickel, silicon, and molybdenum are all stainless steel. These alloys combine to generate a thin but robust coating that interacts with oxygen. It keeps the steel from corroding any further. The demand for Alloy Steel Pipe Manufacturers in India has increased. Stainless steel pipe is typically utilized in industries where corrosion resistance is critical. It’s designed for high-volume service and impact resistance.

Comments