In the manufacturing and pharmaceutical industries, ensuring product quality and safety is paramount. Two critical aspects of this process are Visual Inspection Guidelines in India and Particle Contamination Testing in India. This article will explore these topics, focusing on their importance, application in various industries, and how organizations like FTI Incorporation play a role in these areas.

Visual Inspection Guidelines in India

Pharmaceutical and Parenteral Products

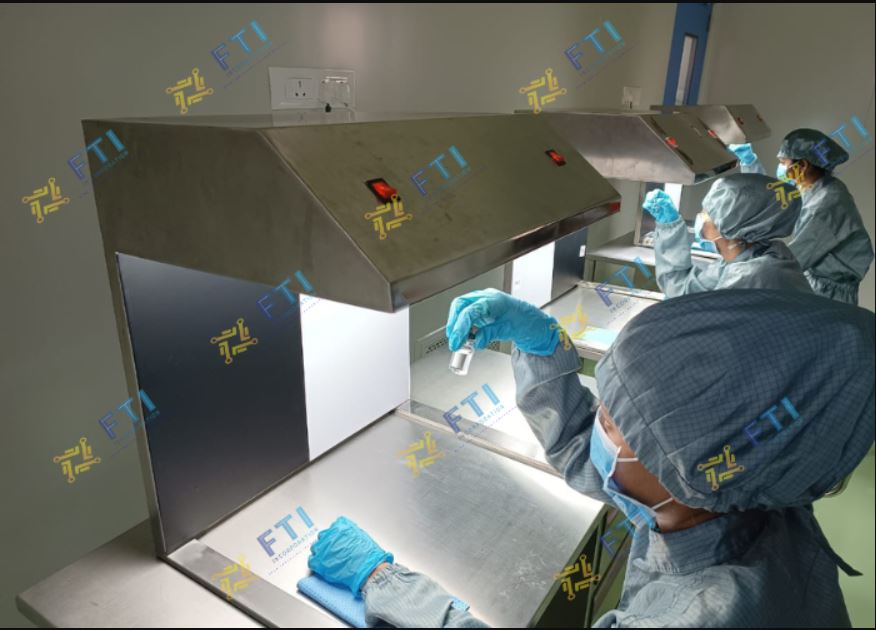

Visual inspection is essential in the pharmaceutical industry, especially for parenteral products (medications administered via injection). The Visual Inspection Guidelines in India emphasize the need for thorough examinations to ensure that products are free from defects, such as particulate matter, discoloration, or foreign substances.

These guidelines help maintain the integrity and safety of pharmaceutical products. Inspectors must be trained to identify issues that could compromise product quality. For instance, a single visible particle in an injectable solution can lead to severe health risks for patients. Therefore, adherence to these guidelines is non-negotiable in the pharmaceutical sector.

Non-Destructive Testing (NDT) - Visual Testing (VT)

Non-Destructive Testing (NDT) is a method used to evaluate the properties of a material, component, or system without causing damage. One of the key techniques within NDT is Visual Testing (VT).

Visual Inspection Guidelines in India provide frameworks for conducting VT effectively. This involves examining materials and structures to detect surface defects, cracks, or irregularities. Industries such as construction, aerospace, and automotive heavily rely on VT to ensure the safety and reliability of their products. Following these guidelines helps maintain high standards and reduces the risk of failures in critical applications.

General Requirements Across Industries

Across various industries, the Visual Inspection Guidelines in India set forth general requirements that ensure consistency and reliability in inspection processes. These include:

- Training and Qualification: Inspectors must be adequately trained and certified to perform visual inspections. This ensures they have the necessary skills to identify potential issues effectively.

- Inspection Procedures: Clear procedures must be established for conducting inspections. This includes defining the criteria for acceptance and rejection based on visual observations.

- Documentation: Proper documentation of inspection results is crucial. This helps in tracking quality control efforts and provides evidence of compliance with regulatory standards.

- Equipment and Environment: The inspection environment should be well-lit and organized, with appropriate tools available for inspectors to perform their duties effectively.

By adhering to these general requirements, industries can ensure that their visual inspections are thorough and reliable.

Particle Contamination Testing in India

The Type of Testing Depends Heavily on the Industry and the Product

Particle contamination testing is vital in ensuring the safety and efficacy of products across various sectors. The type of testing required often depends on the specific industry and the products involved.

For instance, in the pharmaceutical industry, stringent testing is necessary to detect any particulate matter in injectable drugs. Even a tiny particle can cause serious health issues. On the other hand, in the semiconductor industry, testing focuses on detecting contaminants that could affect the performance of microchips.

In general, particle contamination testing methods may include:

- Microscopic Examination: Using microscopes to visually inspect samples for particles.

- Filtration Techniques: Filtering samples to capture particles for analysis.

- Light Scattering Methods: Using laser-based techniques to detect and quantify particles in a fluid.

Finding Particle Contamination Testing Services in India

As industries become more aware of the importance of particle contamination testing, the demand for reliable testing services has increased. In India, several companies specialize in these services, including FTI Incorporation.

FTI Incorporation offers comprehensive particle contamination testing services tailored to the needs of various industries. Their state-of-the-art facilities and experienced professionals ensure that clients receive accurate and timely results. By partnering with such organizations, companies can enhance their quality control processes and ensure compliance with industry standards.

Conclusion

In conclusion, Visual Inspection Guidelines in India and Particle Contamination Testing in India are critical components in maintaining product quality and safety across various industries. The pharmaceutical sector, in particular, relies heavily on visual inspections to ensure that parenteral products are free from defects. Similarly, particle contamination testing is essential in several fields, including pharmaceuticals and semiconductors, to prevent contamination that could compromise product integrity.

Organizations like FTI Incorporation play a significant role in providing training, certification, and testing services that help industries comply with these guidelines and testing requirements. By adhering to established standards and utilizing professional services, companies can ensure the safety and efficacy of their products, ultimately protect consumers and enhance their reputation in the market.

Contact Us

+91-8200487148

+91-9638344845

+91-9654428259

+91-8888860585

[email protected], [email protected]

Office Address

Head office: Forensic Technological Innovation, Incubated at National Forensic Sciences University, Sector 9, Gandhinagar Gujarat 382007, India.

Manufacturing Unit: Shukan Industrial Park, GIDC, Sector 26, Gandhinagar, Gujarat 382610

USA office: 58 Albert Ct, City: Randolph, State: New Jersey Zip code: 07869 USA

Europe office: Jisperveldstaart, 1024AT, Amsterdam

Comments