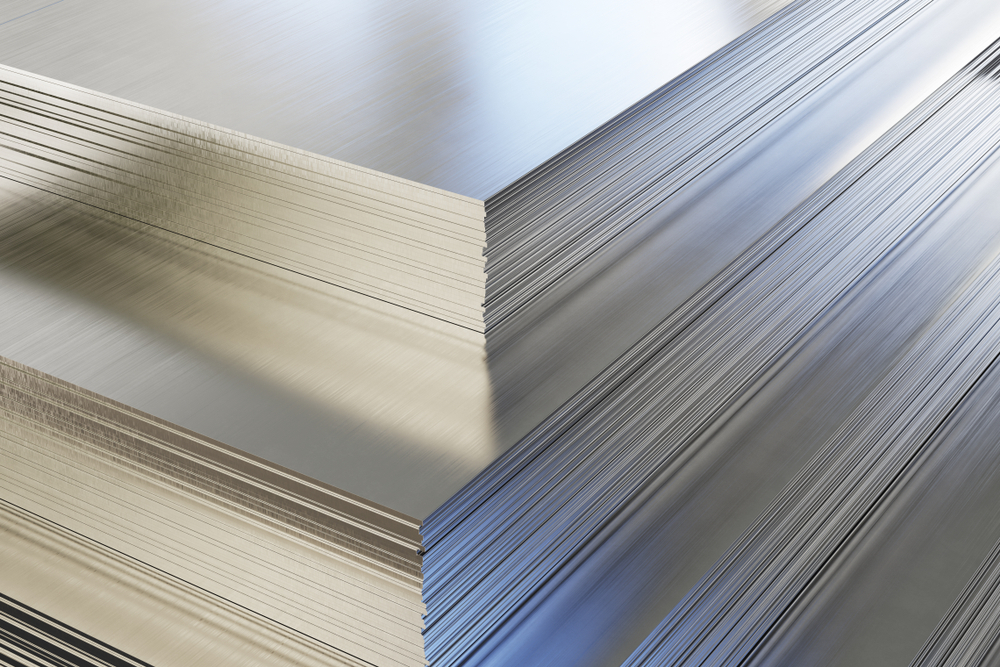

Inconel 800 Plate stands as a testament to the remarkable capabilities of modern engineering alloys. Renowned for its exceptional properties, this nickel-iron-chromium alloy offers a myriad of applications across diverse industries. Let's embark on a journey to uncover the properties and applications of Inconel 800 Plate, delving into the unique characteristics that make it a preferred choice for demanding environments.

Understanding the Composition:

At the heart of the Inconel 800 Plate lies a carefully balanced composition of nickel, iron, and chromium, with additions of aluminum and titanium. This precise alloying creates a material with outstanding resistance to oxidation, carburization, and corrosion in high-temperature environments. The controlled levels of carbon, aluminum, and titanium contribute to the alloy's exceptional strength and stability at elevated temperatures.

Superior Heat Resistance:

One of the most notable properties of the Inconel 800 Plate is its remarkable heat resistance. With a melting point of around 1350°C (2460°F), this alloy maintains its mechanical properties even at elevated temperatures, making it ideal for applications in furnaces, heaters, and thermal processing equipment. Inconel 800 Plate exhibits minimal creep deformation, ensuring long-term reliability in high-temperature environments.

Corrosion and Oxidation Resistance:

Inconel 800 Plate boasts outstanding resistance to both oxidation and corrosion, even in aggressive environments such as sulfur-containing atmospheres and nitriding conditions. This property makes it well-suited for applications in chemical and petrochemical processing, where exposure to corrosive media is commonplace. Additionally, its resistance to chloride stress-corrosion cracking further enhances its suitability for marine and offshore applications.

Applications Across Industries:

The versatility of the Inconel 800 Plate lends itself to a wide range of applications across various industries. In aerospace, it finds use in gas turbine components, where its high-temperature strength and oxidation resistance ensure reliable performance under demanding conditions. In the chemical processing industry, it serves in reactors, piping systems, and heat exchangers, where corrosion resistance is critical.

Conclusion:

Inconel 800 Plate stands as a testament to the relentless pursuit of excellence in materials science and engineering. Its unique combination of properties, including high-temperature strength, corrosion resistance, and oxidation resistance, make it indispensable across a multitude of industries. Whether in aerospace, chemical processing, or thermal engineering, Inconel 800 Plate continues to push the boundaries of what is possible, driving innovation and progress in the modern world.

Comments