In today’s fast-paced industrial environment, safety and reliability are paramount when working at heights. Whether in manufacturing plants, construction sites, or maintenance operations, ladders are essential tools for accessing elevated areas. One type of ladder that has gained significant popularity across industries in India is the FRP (Fiberglass Reinforced Plastic) ladder. Known for their durability, safety features, and versatility, FRP Ladders in India are becoming the preferred choice for professionals in various sectors.

In this article, we will explore the key benefits of FRP ladders, their applications across different industries in India, and the reasons why they are an excellent alternative to traditional metal ladders.

What are FRP Ladders?

FRP ladders are constructed using fiberglass-reinforced plastic, a composite material that combines the strength of fiberglass with the flexibility and durability of plastic. These ladders offer superior mechanical properties, making them ideal for heavy-duty use in harsh environments. They are non-conductive, corrosion-resistant, and fire-resistant, providing a safe and long-lasting solution for working at height.

Key Benefits of FRP Ladders in India

1. Electrical Safety

One of the primary reasons why FRP ladders are favored in industries such as electrical and telecommunications is their non-conductive nature. In India, where electrical hazards are a significant concern in many industries, FRP ladders provide a safe alternative to metal ladders. They do not conduct electricity, reducing the risk of electric shock or electrocution when working near power lines or electrical installations.

2. Corrosion Resistance

FRP ladders are highly resistant to corrosion, making them an excellent choice for industries exposed to moisture, chemicals, or harsh environmental conditions. In India’s diverse climate, which ranges from humid coastal areas to dry and dusty interiors, the corrosion resistance of FRP ladders ensures that they remain structurally sound and durable over time, even in the most challenging environments.

3. Lightweight and Easy to Handle

Despite their heavy-duty strength, FRP ladders are lightweight compared to their metal counterparts. This makes them easier to transport and maneuver, reducing worker fatigue and increasing productivity. Workers can easily carry and set up FRP ladders, especially in large industrial facilities or remote construction sites where frequent movement is required.

4. High Strength and Durability

FRP Ladders in India are designed to withstand heavy loads, making them suitable for industrial applications where workers often carry tools and materials while climbing. These ladders can support significant weight without compromising on stability or safety. Additionally, they are resistant to wear and tear, meaning they can endure frequent use and harsh conditions without deteriorating over time.

5. Fire Resistance

In industries where fire hazards are a concern, such as oil refineries, chemical plants, and manufacturing units, FRP ladders provide an added layer of safety due to their fire-resistant properties. Unlike wooden or metal ladders, FRP ladders do not easily ignite and can withstand exposure to high temperatures, making them an ideal choice for environments with a risk of fire.

6. Cost-Effective in the Long Run

While the initial cost of FRP ladders may be higher than traditional aluminum or wooden ladders, their long-term durability and low maintenance requirements make them a cost-effective solution. Their resistance to corrosion, electrical hazards, and fire significantly reduces the need for frequent replacements, saving businesses money over time.

Applications of FRP Ladders in India

FRP ladders are versatile and can be used across a wide range of industries in India. Some of the most common applications include:

1. Electrical and Telecommunications Industry

FRP ladders are widely used in the electrical and telecommunications sectors in India, where safety around electricity is of utmost importance. Whether installing electrical wiring, repairing power lines, or maintaining telecommunication towers, FRP ladders offer a safe and reliable solution for electricians and technicians.

2. Oil and Gas Industry

The oil and gas industry in India often requires workers to access elevated platforms and equipment in challenging environments. FRP ladders are ideal for this sector due to their fire resistance, corrosion resistance, and lightweight properties. They can be used in refineries, offshore rigs, and other hazardous areas where safety is a priority.

3. Construction and Maintenance

Construction workers frequently rely on ladders to access high areas during building projects. FRP ladders are well-suited for construction sites as they provide the necessary strength and durability to handle heavy loads. Additionally, their lightweight design makes them easy to transport around busy construction sites, improving worker efficiency.

4. Chemical and Industrial Plants

In chemical plants and industrial facilities, workers are often exposed to hazardous substances and corrosive environments. FRP ladders are resistant to chemicals, ensuring that they remain safe and functional even in the presence of aggressive industrial chemicals. Their fire-resistant properties also make them suitable for environments where flammable substances are present.

5. Marine and Offshore Applications

India has a growing maritime and offshore industry, where workers need to access ships, docks, and offshore platforms regularly. FRP ladders are ideal for these environments due to their corrosion resistance in saltwater conditions and lightweight construction, allowing for easy transportation and use on vessels and platforms.

Factors to Consider When Choosing FRP Ladders in India

When selecting an FRP ladder for your business or industrial application, several factors should be considered to ensure you choose the right ladder for the job:

1. Load Capacity

Ensure that the FRP ladder you choose can support the required weight. Heavy-duty FRP ladders are available in various load capacities, typically ranging from 300 to 375 pounds (136 to 170 kilograms), depending on the model.

2. Height Requirements

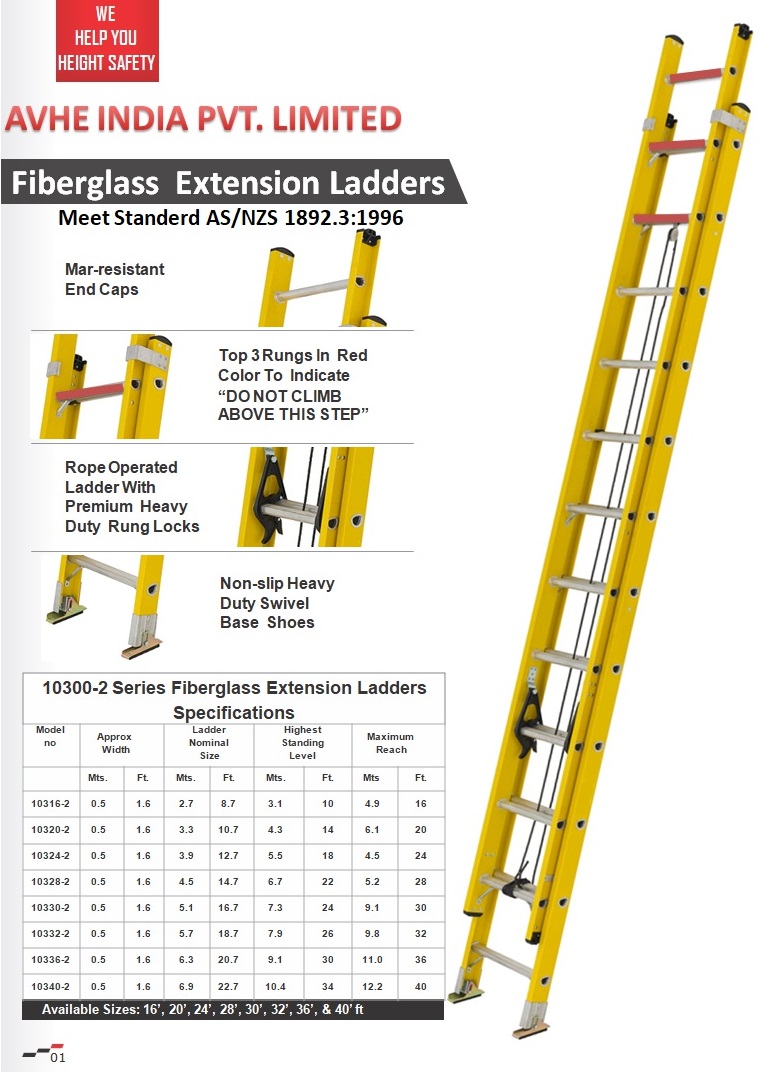

Choose a ladder that meets your height requirements. FRP ladders come in different types, including step ladders, extension ladders, and platform ladders, allowing you to select the appropriate height for your tasks.

3. Non-Slip Features

Safety is paramount when working at heights, so it’s essential to choose an FRP ladder with non-slip feet and rungs. Many FRP ladders are equipped with rubberized feet and ribbed steps to prevent slipping on smooth or wet surfaces.

4. Durability in Harsh Environments

For industries exposed to extreme weather, chemicals, or fire, ensure that the FRP ladder you select has the necessary resistance to withstand these conditions. High-quality FRP ladders are designed to perform in demanding environments, maintaining their strength and integrity over time.

Conclusion

FRP ladders have emerged as a popular choice for professionals across a wide range of industries in India due to their unmatched safety, durability, and versatility. With their non-conductive properties, corrosion resistance, and fire resistance, these ladders provide a reliable solution for working at height in even the most challenging environments.

Whether you are in the electrical, construction, oil and gas, or chemical industry, investing in high-quality FRP ladders ensures that your workers remain safe, productive, and efficient on the job. By offering long-lasting performance and requiring minimal maintenance, FRP ladders are a cost-effective and reliable tool for any industrial application.

For more details, visit us:

Comments