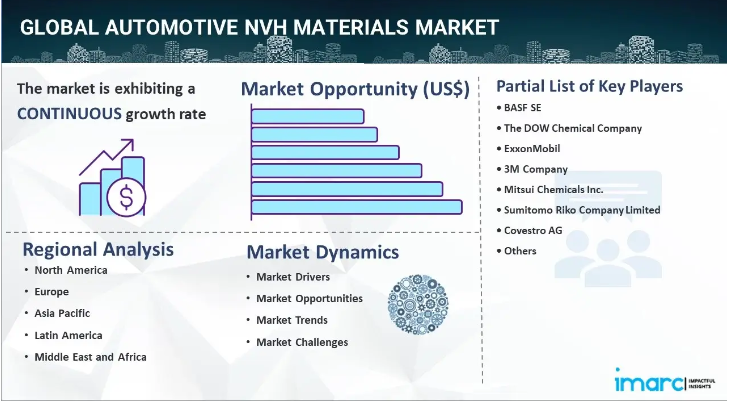

IMARC Group, a leading market research company, has recently released a report titled "Automotive NVH Materials Market Report by Product (Polyurethane, Mixed Textiles Fibers, Fiber Glass, Polyester Fiber, NBR, Polypropylene, PVC, Textile Materials (Synthetic), Textile Materials (Cotton)), Vehicle Type (Passenger Vehicles, LCV, HCV), Application (Trunk Module, Floor Module, Wheel Arches, Cockpit Module, Roof Module, Engine Casing, Bonnet Liners), and Region 2024-2032". The study provides a detailed analysis of the industry, including the automotive nvh materials market trends, size, share and growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

The global automotive NVH materials market size reached US$ 13.0 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 19.6 Billion by 2032, exhibiting a growth rate (CAGR) of 4.5% during 2024-2032.

Request to Get the Sample Report: https://www.imarcgroup.com/automotive-nvh-materials-market/requestsample

The Global Automotive NVH Materials Market: Insights and Trends

Within the automotive industry, the Noise, Vibration, and Harshness (NVH) materials market holds paramount importance, dedicated to refining vehicle comfort and driving experience by addressing unwanted sounds and vibrations. These materials play a pivotal role in enhancing a vehicle's acoustic and vibrational performance, thereby substantially impacting overall quality and user satisfaction. As the automotive landscape continues to evolve, driven by technological innovations and heightened consumer expectations for comfort, the demand for efficient NVH solutions has surged. Manufacturers are increasingly prioritizing NVH materials to ensure that vehicles meet or exceed stringent comfort standards, reflecting the market's pivotal role in shaping the modern automotive experience.

Market Overview

The automotive NVH materials market is a vital sector aimed at enhancing passenger comfort and optimizing vehicle performance by mitigating noise, vibration, and harshness. These materials, spanning foams, rubbers, composites, and textiles, find application across various vehicle components like the engine, dashboard, doors, and flooring, effectively dampening undesirable sounds and vibrations. Market growth is primarily propelled by the automotive industry's imperative to adhere to stringent noise reduction standards while meeting the escalating consumer demand for quieter and more comfortable vehicles. As vehicle production rates rise and the market witnesses an uptick in the adoption of luxury and electric vehicles, the demand for advanced NVH solutions is expected to surge. This heightened demand reflects the industry's broader shift towards refined and high-performance automotive designs, where NVH materials play a critical role in delivering superior driving experiences. Manufacturers are increasingly investing in research and development to innovate new materials and techniques for NVH management, further driving market growth and fostering a competitive landscape geared towards enhancing vehicle comfort and performance. Overall, the automotive NVH materials market remains integral to shaping the future of automotive design and driving experience.

Market Growth

The automotive NVH (Noise, Vibration, and Harshness) materials market is experiencing significant growth, largely driven by the burgeoning global automotive sector. This expansion is particularly noticeable in the rising production rates of both passenger and commercial vehicles, which in turn escalates the demand for advanced NVH materials. Consumers are becoming increasingly knowledgeable about the benefits of noise and vibration reduction in vehicles, which boosts the market as manufacturers strive to meet these heightened expectations with high-quality NVH solutions. Furthermore, the industry is under considerable pressure due to strict regulatory standards imposed worldwide concerning vehicle noise levels. These regulations compel automakers to incorporate sophisticated NVH technologies, thereby propelling the market forward. Additionally, there is a growing inclination towards lightweight and fuel-efficient vehicles, a trend that necessitates the innovation of new NVH materials. These materials must not only be effective in damping noise and vibration but also contribute to the reduction of overall vehicle weight, supporting the automotive industry's shift towards sustainability and enhanced fuel economy. This dual focus on efficiency and environmental consciousness is key to the ongoing development and increased adoption of advanced NVH materials in the automotive sector.

Market Drivers

The automotive NVH (Noise, Vibration, and Harshness) materials market is propelled by several pivotal factors that are shaping the industry's trajectory. One of the primary drivers is the increasing consumer demand for enhanced comfort and luxury within vehicles. This demand has made the integration of advanced NVH materials crucial, as they play a significant role in diminishing cabin noise and improving the overall ride quality, thereby aligning with consumer expectations for a quieter, more comfortable driving experience. Moreover, the global automotive industry is tightly regulated with respect to environmental standards, particularly concerning vehicle noise pollution. These stringent regulations necessitate the adoption of effective NVH solutions, as automakers are required to ensure their vehicles meet the prescribed noise level standards, thereby fueling the market growth. The transition towards electric vehicles (EVs) presents unique challenges and opportunities within the NVH materials market. EVs, devoid of traditional internal combustion engines, demand specialized NVH materials to mitigate different noise and vibration sources, pushing the market towards innovative solutions tailored for electric mobility. Furthermore, the industry’s trend towards vehicle lightweighting, aimed at improving fuel efficiency and reducing emissions, requires the development of NVH materials that are both lightweight and effective. This pursuit of balancing weight reduction without compromising NVH performance spurs ongoing innovation, driving the market towards advanced materials that meet these evolving automotive needs.

Explore the Full Report At: https://www.imarcgroup.com/automotive-nvh-materials-market

Market Forecast

The automotive NVH (Noise, Vibration, and Harshness) materials market is poised for a bright future, buoyed by progressive advancements and broadening application horizons. A key driver for this optimistic market forecast is the anticipated expansion in the automotive industry, particularly with the surging popularity of electric and hybrid vehicles. This shift is expected to substantially elevate the demand for NVH materials, as these modern vehicles present unique noise and vibration challenges that necessitate specialized solutions. As the market responds to this growing demand, there's likely to be a surge in investments aimed in research and development (R&D) activities. The goal here is to forge NVH materials that are not only innovative but also sustainable and more efficient, aligning with the automotive industry's evolving environmental and performance standards. However, the industry faces potential disruptors, such as the intrinsic quietness of electric vehicles and the advent of advanced active noise cancellation technologies, which could reshape the demand for traditional NVH materials. These factors compel the NVH materials market to stay agile, continuously adapting and innovating to meet the fast-evolving needs of the automotive sector, ensuring relevance in the face of shifting industry paradigms.

Breakup by Product:

- Polyurethane

- Mixed Textiles Fibers

- Fiber Glass

- Polyester Fiber

- NBR

- Polypropylene

- PVC

- Textile Materials (Synthetic)

- Textile Materials (Cotton)

Breakup by Vehicle Type:

- Passenger Vehicles

- LCV

- HCV

Breakup by Application:

- Trunk Module

- Floor Module

- Wheel Arches

- Cockpit Module

- Roof Module

- Engine Casing

- Bonnet Liners

Regional Trends

The automotive NVH (Noise, Vibration, and Harshness) materials market exhibits distinctive regional trends, reflecting varying levels of market maturity, regulatory landscapes, and consumer preferences. The Asia-Pacific region stands out as the market leader, primarily fueled by the swift expansion of the automotive industry in populous countries like China and India. This region's growth is bolstered by escalating consumer demands for vehicle comfort and luxury, driving automakers to integrate superior NVH materials. In contrast, North America and Europe maintain substantial market shares, influenced heavily by rigorous regulatory standards aimed at reducing vehicle noise and enhancing overall environmental sustainability. These regions are characterized by a strong preference for high-quality vehicles, prompting a focus on advanced and sustainable NVH materials, particularly in the premium vehicle sector. Emerging markets in Latin America and the Middle East & Africa are poised for growth, driven by the increasing automotive production capacities and a rising emphasis on manufacturing vehicles that meet export-quality standards. These regions are gradually shifting towards higher quality standards, aiming to cater to both domestic and international markets with vehicles that offer improved NVH characteristics, indicating a promising potential for the expansion of the NVH materials market in these areas.

- Asia Pacific

- Europe

- North America

- Middle East and Africa

- Latin America

Challenges and Opportunities

The automotive NVH (Noise, Vibration, and Harshness) materials market is navigating through a landscape filled with both challenges and opportunities. Key challenges include the volatility of raw material prices, which can significantly impact production costs and market prices. Additionally, manufacturers are tasked with the complex challenge of balancing weight, performance, and cost, ensuring that the NVH materials are effective yet economically viable and lightweight. The shift towards electric vehicles (EVs) encapsulates a dual-edged sword; it presents a substantial challenge due to the need for NVH materials that cater to the unique acoustic characteristics of EVs, devoid of traditional internal combustion engine noise. However, this transition also unveils considerable opportunities for innovation in developing new materials that are specifically engineered for the noise and vibration profiles of electric vehicles. The increasing emphasis on sustainability propels the demand for eco-friendly and recyclable NVH materials, mirroring the automotive industry's commitment to environmental responsibility. This trend opens avenues for innovation in bio-based materials and advanced composites, which promise enhanced NVH performance while minimizing environmental footprints. Such developments align with the industry's trajectory towards green solutions, offering opportunities to pioneer NVH materials that are not only effective but also sustainable and aligned with future automotive trends.

Innovations and Trends

The automotive NVH (Noise, Vibration, and Harshness) materials market is at the forefront of innovation, focusing on creating solutions that are lighter, more efficient, and environmentally sustainable. Recent advancements in material science have paved the way for the development of hybrid composites and multi-layer materials. These innovations are designed to provide exceptional noise and vibration damping and are integral in contributing to the overall reduction of vehicle weight, which is a crucial factor in enhancing fuel efficiency and reducing emissions. A notable trend is the emergence of smart materials capable of altering their properties in real time, thereby offering dynamic and optimal NVH control. This adaptability is particularly significant in the context of the evolving automotive landscape, which is increasingly dominated by electric vehicles (EVs). The shift towards EVs necessitates the development of NVH materials that can effectively address the distinct acoustic challenges associated with electric powertrains, such as mitigating noise from electric motors and high-frequency inverters. Furthermore, there is a clear shift towards sustainability within the market, with a growing emphasis on utilizing recyclable and renewable materials for automotive NVH applications. This shift not only supports the industry's environmental goals but also resonates with the global trend towards sustainability, reflecting a commitment to reducing the ecological footprint of automotive manufacturing and contributing to the development of greener vehicles.

Speak to An Analyst: https://www.imarcgroup.com/request?type=report&id=1149&flag=C

Top Companies Operated in Automotive NVH Materials Industry:

- BASF SE

- The DOW Chemical Company

- ExxonMobil

- 3M Company

- Mitsui Chemicals, Inc.

- Sumitomo Riko Company Limited

- Covestro AG

- Celanese Corporation

- Huntsman Corporation

- Lanxess AG

- Borgers AG

Key Highlights of the Report:

- Market Performance (2018-2023)

- Market Outlook (2024-2032)

- Market Trends

- Market Drivers and Success Factors

- Impact of COVID-19

- Value Chain Analysis

- Comprehensive mapping of the competitive landscape

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

Comments