Introduction

Control valves are fundamental components in automated industrial processes, designed to regulate the flow of liquids, gases, or slurries within a system. By precisely modulating the flow rate in response to control signals, these China Control Valves help maintain critical process variables such as pressure, temperature, and fluid level—ensuring efficiency, safety, and product quality.

This article provides a comprehensive overview of control valves, including their core components, operating principles, types, and applications across various industries.

Key Components of Control Valves

Each control valve is composed of several integral parts that work in unison to achieve accurate flow control:

- Valve Body

- The primary housing that contains the internal flow passage and interfaces with the process piping.

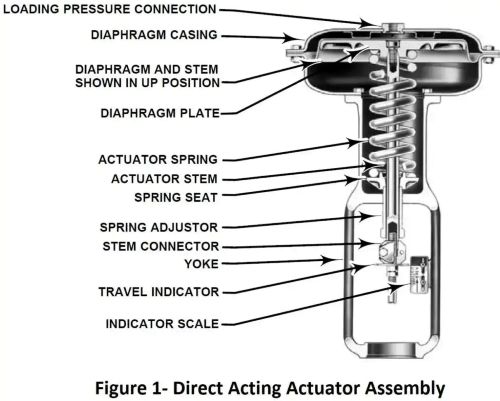

- Actuator

- The driving mechanism that moves the valve stem and plug. Actuators can be powered pneumatically, electrically, or hydraulically.

- Valve Stem

- A rod that transmits motion from the actuator to the valve plug or disc.

- Valve Plug (or Disc)

- The internal element that modulates the flow by moving toward or away from the seat.

- Seat

- The surface against which the valve plug seals when closed to prevent fluid flow.

- Positioner (Optional but essential in modulating valves)

- A control device that ensures the valve reaches the correct position by comparing the setpoint signal with actual valve stem position and adjusting as needed.

How Control Valves Work

Control valves operate as part of a closed-loop control system, adjusting the flow through the valve based on process conditions. The basic operation can be broken down into the following steps:

- Receiving the Control Signal

- The valve receives an input signal (e.g., 3–15 psi pneumatic, 4–20 mA electric, or digital) from a controller, which dictates the desired valve position to achieve a specific flow rate.

- Actuator Movement

- The actuator converts the control signal into mechanical motion.

- Pneumatic actuators use air pressure.

- Electric actuators use motors.

- Hydraulic actuators use pressurized fluid.

- Flow Adjustment

- As the valve plug moves relative to the seat, the opening size of the flow path changes, thereby increasing or decreasing fluid flow.

- Feedback and Positioning

- The positioner monitors valve stem movement and provides real-time feedback, adjusting the actuator to maintain accurate positioning and precise flow control.

Types of Control Valves

Control valves are available in a variety of designs, each optimized for different flow control scenarios and media types:

1. Globe Valves

Offer superior throttling capabilities and are ideal for precise flow regulation. They feature a linear motion plug and a spherical body shape.

2. Ball Valves

Use a rotating ball with a central bore to allow or block flow. These valves are excellent for quick shut-off and low-pressure drop applications.

3. Butterfly Valves

Feature a rotating disc mounted on a shaft. Suited for large flow volumes and low-pressure systems, with compact construction.

4. Diaphragm Valves

Use a flexible diaphragm to modulate flow. Well-suited for corrosive or viscous fluids, especially in sanitary or chemical applications.

5. Gate Valves

Primarily used for on/off service. These valves operate by lifting a gate out of the fluid path, not ideal for throttling applications due to potential flow turbulence.

Applications Across Industries

Control valves are used extensively in industries that require tight control over process variables:

- Oil & Gas: Regulating pressure, flow, and level in extraction and refining operations.

- Chemical Processing: Controlling feed rates, mixing, and reaction conditions.

- Water & Wastewater Treatment: Managing the flow of water, chemicals, and sludge.

- Power Generation: Controlling steam flow, feedwater regulation, and cooling systems.

Example

In a chemical reactor, a control valve may regulate the flow of a reactant. Inaccurate flow can lead to inefficient reactions or safety hazards. A properly sized and positioned control valve ensures precise dosing, stable conditions, and consistent product quality.

Conclusion

Control valves are indispensable tools in process automation, providing dynamic and precise control of fluid movement. By understanding their internal components, how they operate, and the types suited for different applications, engineers and plant operators can ensure reliable and optimized system performance.

The effective selection and application of control valves are central to achieving efficiency, safety, and sustainability in industrial operations. Know more about Google SEO Directory

Comments