In the realm of modern construction, the demand for innovative building materials that combine superior insulation, durability, and versatility is on the rise. Polyurethane Foam (PUF) panels have emerged as game-changers in the industry, and PUF panel manufacturers are at the forefront of this construction revolution. In this article, we will explore PUF panels, their applications, and the pivotal role played by manufacturers in shaping the future of construction.

Understanding PUF Panels:

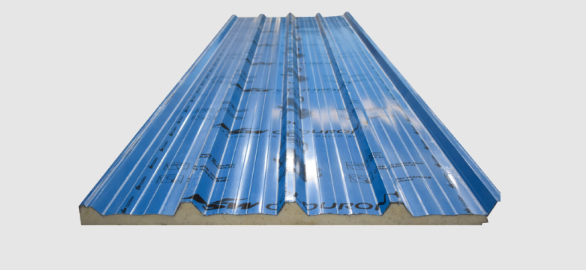

1. What Are PUF Panels? Puf panel manufacturers in delhi , short for Polyurethane Foam panels, are composite building materials consisting of an insulating foam core, typically made of polyurethane, sandwiched between two rigid facings. These facings can be made of various materials, including metal, plywood, or fiber cement.

2. Superior Insulation: PUF panels are renowned for their exceptional thermal insulation properties, making them ideal for maintaining temperature control and energy efficiency in buildings.

Applications Across Industries:

1. Construction: PUF panels find extensive use in both residential and commercial construction for roofing, wall cladding, and partitioning. They offer efficient insulation, structural integrity, and design flexibility.

2. Cold Storage: PUF panels are a staple in the construction of cold storage facilities, ensuring precise temperature control for perishable goods.

3. Cleanrooms: In pharmaceuticals, electronics, and research, PUF panels create sterile environments by preventing contamination and maintaining controlled temperatures.

4. Transportation: PUF panels are employed in the manufacturing of refrigerated trucks, trailers, and containers, guaranteeing the integrity of transported goods.

Advantages of PUF Panels:

1. Thermal Efficiency: PUF panels provide excellent insulation, reducing heating and cooling costs for buildings and ensuring temperature stability.

2. Durability: These panels are resistant to corrosion, weathering, and pests, ensuring longevity and low maintenance.

3. Energy Savings: PUF panels contribute to energy-efficient construction, making them a sustainable choice and reducing carbon footprints.

4. Quick Installation: Pre-fabricated PUF panels are easy to install, saving construction time and labor costs.

5. Design Versatility: Manufacturers offer customization options in terms of thickness, facings, and dimensions, allowing architects to achieve their design goals.

Selecting the Right PUF Panel Manufacturer:

1. Experience and Reputation: Choose manufacturers with a proven track record in producing high-quality PUF panels.

2. Certifications: Ensure that the manufacturer adheres to industry standards and possesses relevant certifications for their products.

3. Customization: Check if the manufacturer can meet your specific project requirements in terms of panel thickness, facings, and design.

4. Technical Support: Opt for manufacturers that offer technical support, including installation guidance and after-sales service.

Conclusion:

PUF panel manufacturers play a pivotal role in modern construction, offering innovative solutions that enhance the efficiency, durability, and sustainability of building projects. These panels have revolutionized various industries, from conventional building construction to specialized applications in temperature-sensitive environments. By providing superior thermal insulation, durability, and customization options, PUF panels empower architects, builders, and project managers to realize their design and energy efficiency goals. Whether you are embarking on a residential, commercial, or industrial project, partnering with a reputable PUF panel manufacturer can be the key to achieving enhanced performance, energy savings, and design flexibility in your construction endeavors.

For more info. visit us:

Comments