In manufacturing and assembly, clear instructions are essential for efficiency and accuracy. Traditional printed manuals often fall short, leading to confusion, mistakes, and delays. Enter advanced solutions like 3D installation manual software and assembly manual software—digital tools that simplify complex processes by providing interactive, 3D guides. This article discusses the advantages of these innovative tools and how they improve productivity and accuracy in assembly operations.

Enhancing Clarity with 3D Installation Manual Software

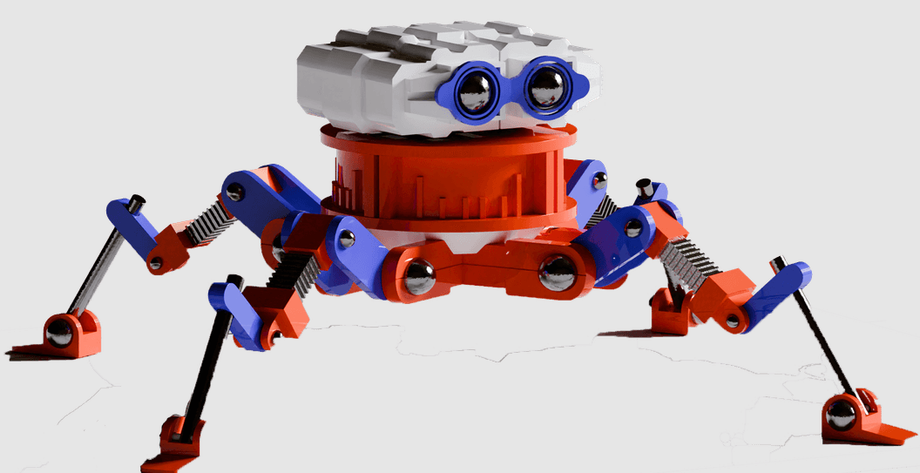

When it comes to understanding intricate assembly processes, static diagrams and text can be limiting. 3D installation manual software brings instructions to life by enabling users to view each step in three-dimensional detail. This software allows for rotations, zooming, and interactive views, helping users understand each phase of the installation process more intuitively.

The benefits of 3D installation software extend beyond clarity. Companies using this tool find that it reduces assembly errors, shortens training times, and increases efficiency on the production floor. This software proves invaluable in industries where precision is critical, such as automotive, electronics, and furniture manufacturing. By leveraging 3D installation manuals, businesses can ensure that each component is assembled correctly, reducing the likelihood of costly mistakes.

Streamlining Operations with Assembly Manual Software

Unlike traditional manuals, assembly manual software enables a dynamic approach to managing and distributing assembly instructions. This software is ideal for manufacturing and assembly environments where processes often change, as updates can be made easily and instantly distributed across teams. Companies depending on current data and efficient processes must be flexible enough.

Assembly manual software also supports multimedia elements, such as videos, animations, and interactive steps, allowing employees to learn and execute tasks more effectively. For example, instead of reading complex paragraphs of text, workers can follow visual cues, making the entire process faster and reducing training requirements. Additionally, this software integrates seamlessly with other digital tools, providing analytics and feedback that managers can use to optimize assembly processes further.

The Impact of Digital Manuals on Business Efficiency

The shift from traditional to digital manuals has profound implications for business operations. Both 3D installation manual software and assembly manual software enhance efficiency by making instructions clearer and more engaging. In industries where accuracy is vital, these tools significantly reduce the potential for assembly errors, ensuring the goods satisfy consumer expectations and quality criteria.

Furthermore, these digital tools support continuous improvement in production by allowing businesses to analyze assembly data and adjust processes as needed. With detailed insights and analytics, companies can identify bottlenecks, improve workflow, and achieve greater consistency in their production lines.

Conclusion

3D installation and assembly manual software are revolutionizing how businesses approach complex assembly processes. Tools like 3D installation manual software and assembly manual software improve clarity, reduce errors, and boost productivity, making them invaluable for any industry focused on efficient and accurate assembly. For those looking to integrate these advanced solutions, easemble.com offers innovative software tailored to meet the unique needs of modern manufacturing, transforming how instructions are created and followed in assembly environments.

FOR MORE INFO :-

Comments