The world is moving fast toward eco-friendly solutions. Electronics is no exception. Today, sustainability is not just a trend. It’s a necessity. From smartphones to industrial controls, electronics touch every part of life. But how do we make these devices greener?

That’s where PCB prototype manufacturing and supplier companies come in. They are now more than just component producers. They’re becoming key players in designing eco-conscious products. With the support of experts PCB prototype manufacturing services, companies can reduce waste, boost efficiency, and support a cleaner planet.

Let’s dive into how this transformation is taking place.

Why Sustainability Matters in Electronics

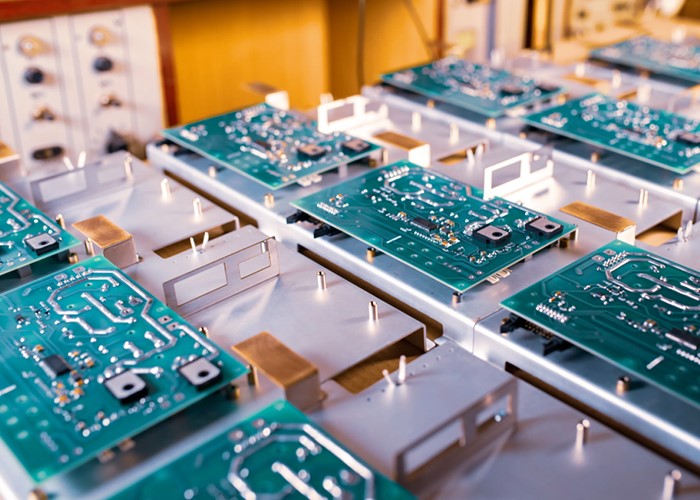

Modern electronics rely heavily on printed circuit boards (PCBs). But traditional PCB processes use hazardous materials, consume large amounts of energy, and create significant waste.

For example:

- Toxic chemicals are used in etching and plating.

- Lead-based soldering materials still exist in older practices.

- Unused boards and scrapped materials increase e-waste.

Sustainable practices aim to fix all that.

The Shift Toward Greener PCBs

Experts PCB prototype manufacturing services are leading this change. These professionals use cleaner technologies and smarter processes to design PCBs with minimal environmental impact.

Here’s how they help:

- Lead-free soldering and halogen-free laminates

- Closed-loop water systems to reuse water in the process

- Use of recycled copper for circuit layers

- Designing boards for longer life and easier recycling

This means lower carbon footprints and fewer hazardous materials in landfills.

The Role of PCB Prototypes Manufacturing and Supplier Companies

Now, let’s look at what PCB prototypes manufacturing and supplier companies do in this space. Their role is evolving beyond supplying fast-turn boards.

They now:

- Collaborate with design engineers to select eco-friendly materials

- Recommend board layouts that reduce layers and save resources

- Offer energy-efficient manufacturing processes

- Help clients follow RoHS and REACH compliance standards

These steps reduce waste at the prototyping stage, preventing costly changes later in full production.

Making Sustainability Work from Day One

Early design choices matter. Experts PCB prototype manufacturing services work closely with product teams to align on sustainable goals early on.

For example:

- Selecting recyclable substrates like polyimide or FR-4

- Reducing component count to simplify end-of-life disassembly

- Ensuring precise board thickness to avoid material overuse

This collaboration speeds up product cycles and reduces environmental impact at every stage.

Benefits for Businesses

Using green practices doesn’t just help the planet—it helps companies too. Partnering with PCB prototypes manufacturing and supplier companies that focus on sustainability brings many advantages.

Some include:

- Cost savings through reduced material and energy waste

- Faster compliance with environmental regulations

- A stronger brand image among eco-conscious customers

- Better product reliability through smart design

When experts PCB prototype manufacturing services are involved, you also get deep technical insight. That means fewer mistakes, faster iterations, and better performance.

Sustainable Technology Is the Future

The global demand for cleaner electronics is only growing. Consumers want transparency. Governments want tighter regulations. And companies want long-term savings.

So, who leads this future? It's the engineers, the innovators, and the PCB prototypes manufacturing and supplier partners that make green technology possible.

By choosing expert PCB prototype manufacturing services, businesses can stay ahead in this shift. Together, we can build not just smarter devices, but cleaner ones too.

Final Takeaway

In a world that demands both innovation and responsibility, PCB prototype manufacturing and supplier companies are at the center of sustainable change. With the help of experts PCB prototype manufacturing services, the electronics industry is finding greener paths without slowing down innovation.

It’s not just about building circuits, it’s about building a better future.

Comments