In today’s global marketplace, products are often transported over long distances and face various environmental challenges. Ensuring that your products arrive in perfect condition is crucial for maintaining brand reputation and customer satisfaction. One of the most reliable ways to test packaging durability and product resilience is through a Drop Tester.

What is a Drop Tester?

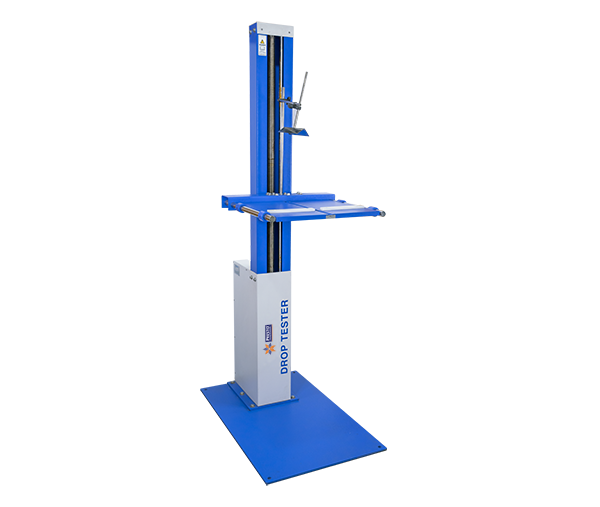

A Drop Tester is a testing instrument used to simulate the impact and shock a product might experience during shipping and handling. By subjecting the product to controlled drops from various heights and angles, manufacturers can assess how well packaging withstands the rigors of transit. This helps identify weaknesses in packaging design and material, ensuring that products remain protected during their journey.

Why is Drop Testing Important?

Packaging is not just about protecting the contents from dust or dirt; it’s about shielding the product from physical damage caused by impacts, such as drops or knocks. Even small drops can cause significant damage, especially to fragile items like electronics, glass containers, or pharmaceuticals. The Drop Tester provides valuable insights into:

- Impact Resistance: Simulating real-life situations where products might fall or be dropped, a Drop Tester measures the packaging’s ability to absorb shocks without damaging the product inside.

- Packaging Integrity: Identifying weak points in packaging materials or design, helping manufacturers make informed decisions about improving packaging before it hits the market.

- Cost Efficiency: Preventing damaged products from reaching customers can significantly reduce returns and complaints, saving businesses the cost of replacements and improving overall customer satisfaction.

How Does a Drop Tester Work?

A typical Drop Tester consists of a platform, a drop mechanism, and adjustable settings to control the height from which the product is dropped. Here's how it works:

- Product Placement: The item to be tested is placed inside the packaging, which is then positioned on the drop platform.

- Controlled Drop: The Drop Tester simulates a fall by releasing the package from a predetermined height. This height can be adjusted based on the product type and expected shipping conditions.

- Impact Simulation: The package is subjected to multiple drops from different heights and angles to mimic various scenarios that could occur during shipping or handling.

- Results Analysis: After the test, the product is examined for any signs of damage or degradation. The packaging’s ability to protect the contents is then evaluated based on the results.

Benefits of Using a Drop Tester

- Improved Product Protection: By identifying vulnerabilities in packaging, businesses can enhance their packaging designs to better protect products during shipping, minimizing the risk of damage.

- Regulatory Compliance: In some industries, such as pharmaceuticals or electronics, packaging must meet specific durability standards. A Drop Tester ensures that your packaging adheres to these guidelines.

- Customer Satisfaction: Delivering products in perfect condition boosts customer trust and satisfaction. A well-tested package ensures fewer returns and complaints, strengthening brand loyalty.

- Cost Savings: Preventing damaged goods from reaching customers helps reduce returns, replacements, and warranty claims, ultimately saving businesses money.

Industries That Benefit from Drop Testing

Several industries can benefit from using a Drop Tester, including:

- Electronics: Ensuring delicate devices like smartphones, laptops, and TVs remain intact during transport.

- Pharmaceuticals: Protecting fragile medication containers and vials that may be sensitive to impacts.

- Consumer Goods: Testing packaging for household items, toys, and other products vulnerable to drops and impacts.

- Food and Beverage: Ensuring packaging can protect fragile food containers, such as glass bottles, during transportation.

Conclusion

In the fast-paced world of e-commerce and global shipping, protecting your products during transit is crucial. A Drop Tester offers an invaluable tool for simulating real-world shipping impacts, helping businesses identify packaging weaknesses before they reach customers. By investing in drop testing, companies can ensure their products are delivered intact, ultimately improving customer satisfaction, reducing costs, and strengthening their brand reputation.

Email :- [email protected]

Call Now: +919210903903

Comments