The U.S. Wafer Handling Robots Market has experienced significant expansion over the past few years, driven by the growing demand for automation in semiconductor manufacturing processes. Among the key drivers fuelling this growth is the rising focus on semiconductor research and development (R&D), as the need for faster, more efficient, and precise manufacturing methods becomes increasingly critical. As the world moves towards a more digital and interconnected future, the semiconductor industry is tasked with producing higher-quality and more complex devices, thus amplifying the need for advanced robotic systems to handle delicate wafer processing tasks.

This article delves into the current trends, growth drivers, and challenges shaping the U.S. wafer handling robots market, with a particular emphasis on the impact of the growing semiconductor R&D initiatives.

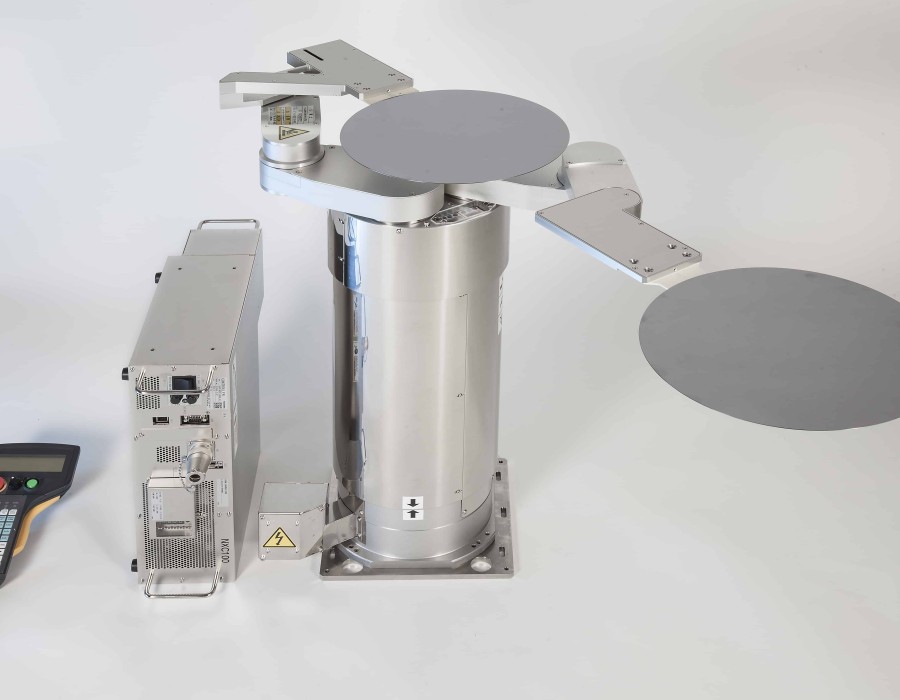

Overview of Wafer Handling Robots

Wafer handling robots are specialized machines designed to automate the process of handling and transferring silicon wafers during semiconductor manufacturing. These robots are essential in maintaining the integrity of wafers, which are often fragile and require high-precision handling to avoid damage during production. The automation of wafer handling not only reduces the risk of human error but also boosts efficiency, enabling manufacturers to increase throughput and meet the rising demand for semiconductor components.

Semiconductor manufacturers face the challenge of producing increasingly complex and miniaturized chips, and as a result, the precision, speed, and reliability of wafer handling robots have become more critical than ever. Wafer handling robots are used in a variety of applications, including wafer loading, unloading, sorting, and inspection.

Growth Drivers of the U.S. Wafer Handling Robots Market

1.Rising Focus on Semiconductor R&D

The ongoing advancements in semiconductor research and development (R&D) have significantly contributed to the growth of the wafer handling robots market. As new technologies such as 5G, artificial intelligence (AI), and the Internet of Things (IoT) continue to gain prominence, the demand for more sophisticated and higher-performing semiconductors has risen. To keep up with these developments, semiconductor manufacturers are investing heavily in R&D to develop new materials, processes, and chip designs.

This growing focus on R&D leads to an increased demand for advanced automation solutions, including wafer handling robots, to support the development of next-generation semiconductor devices. In particular, research efforts related to miniaturization, 3D chip stacking, and the integration of new materials like gallium nitride (GaN) and silicon carbide (SiC) require highly accurate wafer handling systems capable of supporting more complex manufacturing processes.

2.Increasing Demand for High-Performance Semiconductors

The global demand for semiconductors continues to grow, fuelled by the rise of connected devices, autonomous vehicles, renewable energy systems, and more. These applications require increasingly powerful chips that are more compact, efficient, and capable of handling complex tasks. As the industry pushes the boundaries of semiconductor capabilities, wafer handling robots must keep pace with the need for precision and speed in processing these advanced chips.

In particular, high-performance applications such as 5G infrastructure and AI demand advanced wafer handling capabilities, as these chips require sophisticated packaging and assembly techniques. With wafer handling robots facilitating these processes, manufacturers can increase productivity, reduce defects, and improve the overall quality of their products.

3.Automation and Industry 4.0 Adoption

As part of the broader Industry 4.0 trend, automation is transforming various manufacturing sectors, including the semiconductor industry. The adoption of automated systems, including wafer handling robots, allows manufacturers to streamline production processes and reduce reliance on manual labor, which can be error-prone and costly. Automation also facilitates real-time monitoring and adjustments, leading to improved quality control and operational efficiency.

Industry 4.0 also emphasizes the integration of advanced technologies such as artificial intelligence, machine learning, and data analytics into manufacturing systems. Wafer handling robots equipped with these technologies can optimize their performance, predict maintenance needs, and reduce downtime, contributing to increased productivity and profitability for semiconductor manufacturers.

4.Improved Precision and Reliability

Wafer handling robots provide unmatched precision, which is critical in semiconductor manufacturing, where even the smallest mistake can lead to defects or production delays. The handling of fragile silicon wafers requires high levels of accuracy to ensure that the wafers are not damaged during processing. Robots can operate with minimal human intervention, reducing the likelihood of errors and improving overall production reliability.

Furthermore, advancements in robotic technology, such as improved sensors, enhanced control systems, and smarter algorithms, have enabled wafer handling robots to become more precise and efficient over time. These improvements are crucial as manufacturers work with increasingly smaller and more delicate wafers, where even slight variations in handling can result in significant product losses.

Challenges in the Wafer Handling Robots Market

Despite the growth drivers, several challenges remain in the U.S. wafer handling robots market.

1.High Initial Investment Costs

The cost of implementing robotic systems for wafer handling can be prohibitively high, especially for smaller semiconductor manufacturers or research institutions. The price of advanced robots, along with the associated costs of installation, training, and maintenance, can deter some potential customers from adopting these systems. However, as technology advances and production volumes increase, the cost of wafer handling robots is expected to decrease, making them more accessible to a wider range of manufacturers.

2.Integration with Existing Systems

Semiconductor manufacturers often face challenges in integrating new robotic systems into their existing production lines. Older manufacturing plants may not be designed to accommodate the latest robotic technologies, requiring significant modifications to infrastructure and processes. Ensuring smooth integration between wafer handling robots and other parts of the semiconductor manufacturing process is crucial for maximizing efficiency and minimizing disruptions.

3.Technological Complexity and Need for Skilled Workforce

While automation has the potential to reduce the reliance on manual labor, the complexity of modern wafer handling robots requires a skilled workforce to operate and maintain these systems. Semiconductor manufacturers need to invest in training and upskilling their employees to ensure that they can effectively manage and troubleshoot advanced robotic systems.

Conclusion

The U.S. wafer handling robots market is poised for continued growth, driven by the increasing focus on semiconductor R&D, the rising demand for high-performance semiconductors, and the adoption of automation and Industry 4.0 technologies. As semiconductor manufacturers continue to push the boundaries of technology, the need for advanced robotic systems capable of handling delicate wafer processing tasks will become even more pronounced.

While there are challenges such as high initial investment costs and the complexity of integrating new systems, the long-term benefits of wafer handling robots—improved precision, efficiency, and reduced defects—make them a valuable investment for semiconductor manufacturers. As the industry evolves and more research and development efforts are directed toward advanced semiconductor technologies, wafer handling robots will play an increasingly critical role in ensuring the efficient and precise production of next-generation chips.

Comments