Fast prototyping is the course of rapidly making actual parts to use for testing the look, fit, or potentially usefulness of a plan. Customary assembling cycles can require weeks or months to set up, also large number of dollars. For that reason quick prototyping is so significant. It saves time, however cash also, by and large.

Specialist co-ops

There are many organizations that offer fast prototyping administrations, and there are many administrations presented by them. A portion of the famous administrations are inspected beneath.

Sorts of Assembling

There are two fundamental kinds of model assembling: added substance and subtractive. Subtractive cycles include more established strategies like processing (counting CNC processing). Machines start with a larger than usual block of material and steadily remove material until the part is done. Added substance processes, like 3D printing, are generally more current and they work by making endless supply of material until the part is done. The two kinds of assembling can require hours or days to finish however each interaction enjoys interesting benefits.

3D Printing

One quickly developing interaction is called 3D printing. It is one of the freshest and most reasonable cycles that anyone could hope to find. It is an added substance process where layers of material, generally a plastic or a photopolymer, are developed each in turn more than a few hours to make parts. A few printers could utilize genuine metal. There are multiple ways of making the layers. One includes an inkjet type framework, where a fluid photopolymer is splashed across a table looking like the layer and dried by bright lights. Another framework expels tiny pieces of plastic, similar as a minuscule craft glue firearm, and a mechanical situating framework puts the plastic in the right regions to make a layer with the right blueprint. Still another framework utilizes a laser to focus on a layer of powder to combine little regions to make a layer with the legitimate diagram. There are different frameworks out there, however this is a decent outline of this interaction.

Stereolithography (SLA)

Stereolithography, or SLA, is one of the most seasoned and most famous fast prototyping methods out there. It offers a decent degree of solidarity, surface detail, and cost. SLA is an added substance process that includes a tank of fluid photopolymer. A laser framework fixes the proper segments of each layer.

Particular Laser Sintering (SLS)

Particular Laser Sintering, or SLS, is another well known help offering. It is generally more costly and parts frequently have a harsher completion than SLA yet there are a more extensive scope of materials accessible, including metal, plastic, clay and glass.

Urethane Castings

At the point when different models are required, it is at times more efficient to have the parts formed utilizing a urethane projecting strategy. The average amounts included are around ten to one hundred. An expert part is normally made utilizing SLA and afterward a silicone RTV shape is made around it. Then, at that point, the castings are produced using a urethane or polyurethane. These urethanes arrive in a wide assortment of material properties and varieties, which can be a major advantage to the client.

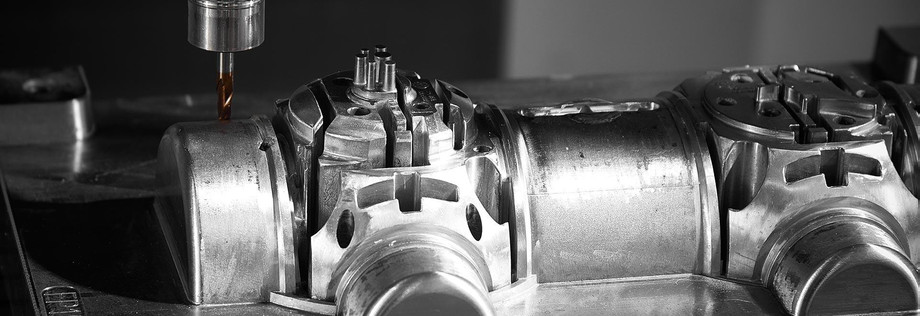

CNC Machined Plastic

Another assistance that a few organizations offer is machined plastic parts. Typically CNC factories make parts utilizing metal like steel or aluminum, however they can likewise be utilized to make model parts or low-volume parts out of a wide range of sorts of plastic.

End

This article takes care of a portion of the famous administrations offered, yet there are a lot more that can be investigated internet, including 3D filtering, metal castings, and quick infusion shaping.

For More Info:-

Rapid Prototype Molding Services

Low Volume Plastic Injection Molding USA

Comments