The PowerFlex 523 AC Drive is made by Allen-Bradley, a branch of Rockwell Automation and a manufacturer of variable frequency drives (VFDs). In many industrial applications, the drive's function is to control the three-phase AC motors' speed and torque. To improve system dependability, the Allen Bradley PowerFlex 523 AC Drive has a variety of fault prevention features. Some of the key traits that improve its reliability include the following:

1. Overload Protection

The drive incorporates motor overload protection to stop excessive current draw from happening that can damage the motor or other parts. It monitors the motor's current continually and tripped or sounds an alarm if the current exceeds a certain limit.

- Current Monitoring: The drive continually keeps track of the current going to the motor. To measure the current, it makes use of current sensors or other monitoring devices.

- Current Threshold: The drive is preset with the overload trip point, sometimes referred to as the current threshold value. This threshold is the maximum current that the motor can safely handle.

- Comparison and Response: Measured current is compared to the overload trip point by the drive. When the current exceeds the threshold, the drive safeguards the system by taking the appropriate action.

- Alarm or Trip: When an overload condition is detected, the drive has the ability to emit an alarm to notify the system operator or maintenance personnel. It can also initiate a trip, which immediately stops the drive and cuts off power to the motor.

2. Short Circuit Protection:

To prevent issues with the motor or the cables that supply it, the PowerFlex 523 is equipped with short circuit safety mechanisms. When a short circuit happens, the current can be quickly switched off to prevent damage.

- Monitoring Current: The PowerFlex 523 continuously monitors the current flow via the motor and associated circuits. It typically uses current sensors or other monitoring equipment to measure the current.

- Detection of Short Circuit Fault: An sudden and significant increase in current results from a short circuit breakdown. The drive's short circuit safety mechanism notices this sudden current spike and recognises it as a short circuit issue.

Also Read :- Rockwell Automation PowerFlex 523 AC Drive

3.Overvoltage and Undervoltage Protection:

The drive monitors the incoming power source's voltage and prevents overvoltage and undervoltage problems. If the voltage is either inside or outside of the permitted range, the drive may trip or sound an alarm to safeguard the system.

- Voltage Monitoring: The voltage of the incoming power source is continually monitored by the PowerFlex 523. To detect the voltage level, it frequently makes use of voltage sensors or other monitoring tools.

- Overvoltage Protection: The drive initiates its overvoltage safety system if the measured voltage rises over a certain threshold, signalling an overvoltage problem. The following safety precautions might be part of this system.

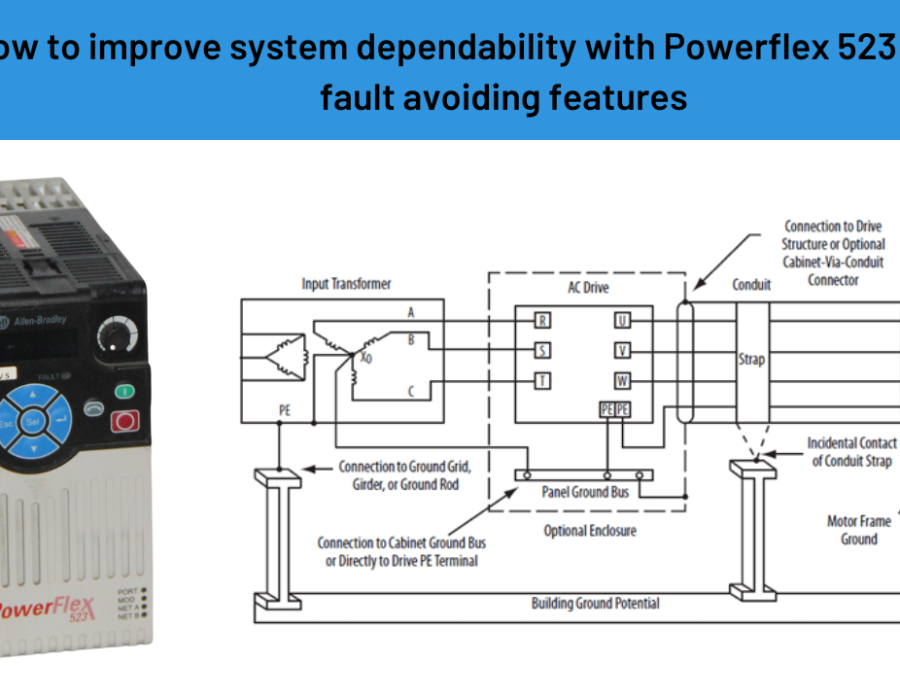

4. Ground Fault Protection:

Ground faults can result in both safety issues and damage to electrical equipment. The PowerFlex 523 offers ground fault protection to identify and minimise such problems. It keeps track of the current flow between the motor phases and ground and alerts the user or trips the circuit when an imbalance indicative of a ground fault is discovered.

- Current Monitoring: The PowerFlex 523 continually measures the current flowing between the motor phases and ground. It typically uses current sensors or other monitoring equipment to measure the current.

- Detection of Ground Fault: A ground fault happens when an unapproved route is constructed between one or more motor phases and ground. As a result, the current flow becomes imbalanced. The drive's ground fault protection mechanism detects this imbalance and recognises it as a ground fault.

5.Thermal Protection:

The drive has thermal protection features in place to stop the motor from overheating. It monitors the temperature of the motor and, if it increases over acceptable limits, can either reduce output power or sound an alert.

- Temperature Monitoring: The PowerFlex 523 AC Drive continually measures the motor's temperature. Temperature sensors or other monitoring tools are typically used to measure the motor's temperature.

- Temperature Threshold: A temperature threshold that is set into the drive serves as a representation of the motor's highest safe operating temperature. This threshold is often based on the motor's specs and temperature limitations.

- Comparison and Response: The drive compares the difference between the motor temperature data and the temperature threshold. If the temperature exceeds the threshold, the drive signals overheating and takes necessary action to safeguard the motor and the system.

- Stall Detection: The PowerFlex 523 has the capacity to recognise situations with an excessive load or motor stalls. In order to protect the system, the drive can respond to stall detection by reducing motor speed or initiating a fault reaction.

- Motor Speed Monitoring: The motor's speed is continuously monitored by the PowerFlex 523. To ascertain the motor's rotational speed, data from motor encoders or speed sensors is frequently used.

- Stall Detection Threshold: The drive's built-in stall detection threshold represents the motor's anticipated lowest speed under usual conditions. This threshold is determined by the motor's specs and operating characteristics.

- Comparison and Detection: The observed motor speed is compared to the threshold for stall detection by the drive. If the speed falls below the threshold, the drive detects it as a stall situation, denoting a significant reduction in or complete halt of motor rotation.

6.Fault Logging and Diagnostics:

The drive keeps note of any problems it encounters and provides diagnostic information to aid with upkeep and troubleshooting. This assists in identifying recurring issues and enhancing system performance.

By adopting these fault prevention measures, the PowerFlex 523 AC Drive aims to prolong the entire system's dependability and lifespan by preventing or limiting potentially detrimental occurrences. It helps save downtime, improve safety, and preserve expensive equipment in industrial applications.

When you require variable frequency drives for your manufacturing industry system, Asteam Techno Solutions Pvt Ltd is here to help you. With an inventory of obsolete and surplus spare parts and a team of qualified engineers, there’s no breakdown or fault we cannot solve. Wherever you are in the world, Asteam Techno Solutions Pvt Ltd is the best Industrial Automation parts supplier and solutions provider in India as well as globally. Get support for all types of equipment from AC, DC and servo drives through to PLCs, HMIs and other automation parts. Hard to find parts are a specialty, with fast shipping on obsolete parts from all brands including Allen Bradley, Mitsubishi, Omron, Siemens, Schneider, Moxa, VIPA and more.

Comments