HDPE SHEETS are versatile materials widely used across various industries for their durability, flexibility, and environmental benefits. This comprehensive guide explores the uses, advantages, and applications of HDPE sheets, highlighting their importance in construction, packaging, manufacturing, and beyond.

Understanding HDPE Sheets

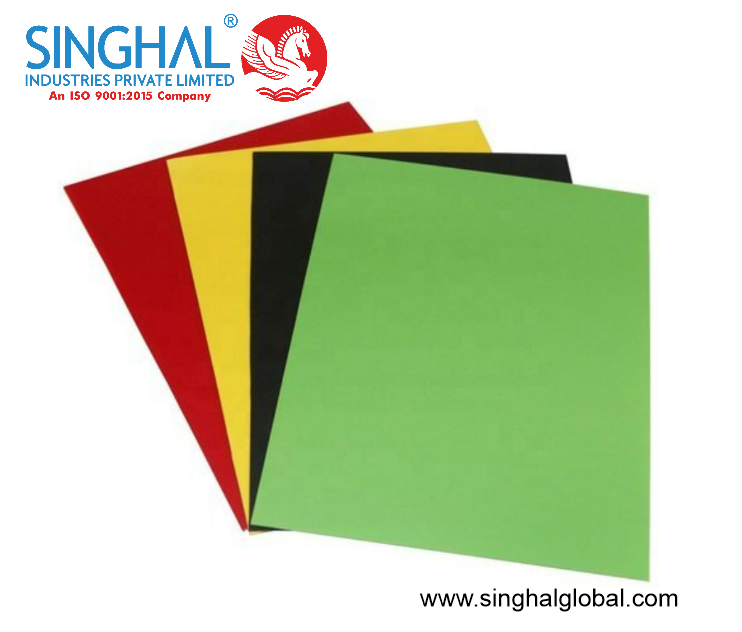

HDPE sheets are manufactured from high-density polyethylene, a thermoplastic polymer known for its high strength-to-density ratio. Key characteristics include:

- Durability: HDPE sheets are resistant to impact, moisture, chemicals, and corrosion, making them suitable for both indoor and outdoor applications.

- Flexibility: They are available in various thicknesses and sizes, offering flexibility in design and application.

- Recyclability: HDPE is recyclable, contributing to sustainability efforts by reducing environmental impact.

Advantages of HDPE Sheets

- Chemical Resistance: HDPE sheets are highly resistant to chemicals, acids, and alkalis, making them ideal for use in laboratories, chemical processing facilities, and industrial applications where corrosion resistance is crucial.

- Weather Resistance: They withstand harsh weather conditions, UV exposure, and temperature variations, making them suitable for outdoor applications such as signage, playground equipment, and marine environments.

- Impact Resistance: HDPE sheets absorb impact without fracturing, making them suitable for protective barriers, vehicle liners, and applications requiring impact resistance.

- Ease of Fabrication: HDPE sheets can be easily cut, welded, and formed into various shapes and sizes, offering versatility in manufacturing and construction projects.

Applications of HDPE Sheets

HDPE sheets find diverse applications across industries:

- Construction: Used for moisture barriers, wall cladding, flooring, and protective linings in construction projects.

- Packaging: Utilized in packaging materials such as crates, trays, and containers due to their lightweight, moisture resistance, and durability.

- Manufacturing: Employed in manufacturing processes for machine parts, tanks, and equipment components due to their chemical resistance and ease of fabrication.

- Agriculture: Used for lining irrigation channels, ponds, and reservoirs to prevent seepage and conserve water.

- Transportation: Applied in vehicle components, cargo liners, and truck bed liners for their impact resistance and durability.

Environmental Considerations

HDPE sheets contribute to sustainability efforts through:

- Recyclability: They can be recycled into new products at the end of their service life.

- Reduced Environmental Impact: HDPE sheets have a lower carbon footprint compared to alternative materials like PVC (Polyvinyl Chloride) and metals.

Conclusion

HDPE sheets are indispensable materials valued for their durability, chemical resistance, and environmental benefits across diverse industries. From construction and packaging to manufacturing and agriculture, their versatility and performance make them a preferred choice for applications requiring robust, reliable materials. Understanding the uses, advantages, and environmental considerations of HDPE sheets underscores their importance in modern industrial and commercial settings, promoting sustainability and efficient resource management.

Comments