In the fast-paced world of manufacturing, precision and reliability are critical, especially in the fastener production industry. One of the key components in this sector is the thread rolling machine, a vital tool that ensures the efficient and accurate production of bolts, screws, and other fasteners. For businesses looking for a reputable thread rolling machine supplier in India, understanding the features, benefits, and offerings of various manufacturers is essential.

What is a Thread Rolling Machine?

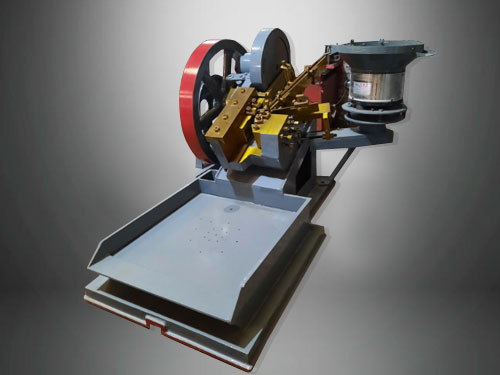

Thread rolling machine are specialized equipment used to create threads on cylindrical metal rods. The process involves rolling the metal between two dies to form the desired thread profile, which is known for its superior strength and finish compared to cut threads. This method not only enhances the integrity of the threads but also contributes to the overall efficiency of production.

Key Features of Thread Rolling Machines

High Precision: The machines are designed to provide high precision in the thread-forming process, ensuring consistency and repeatability across batches.

Durability: Manufactured using high-quality materials, thread rolling machines are built to withstand continuous operation and heavy workloads.Bolt Making Machine Manufacturers In India

Versatility: They can accommodate various thread sizes and profiles, making them suitable for a wide range of fasteners, including bolts and screws.

Cost-Effectiveness: By producing stronger threads with minimal material wastage, businesses can save on production costs and enhance profitability.

Leading Thread Rolling Machine Suppliers in India

Several manufacturers in India specialize in thread rolling machines, each offering unique technology and services tailored to meet the diverse needs of the fastener industry.

XYZ Engineering Solutions: Known for their innovative designs and robust machinery, XYZ Engineering Solutions offers a range of thread rolling machines that cater to both small-scale and large-scale manufacturing units.

ABC Fasteners: With a strong focus on quality and customer satisfaction, ABC Fasteners has established itself as a leading supplier of thread rolling machines, emphasizing after-sales service and technical support.

PQR Industries: PQR Industries provides customized solutions and has gained recognition for its cutting-edge technology in thread rolling machinery, ensuring clients receive the best possible equipment for their needs.

Trimming Machine Manufacturer: The Backbone of Fastener Production

While thread rolling machines are vital for producing the threads on fasteners, trimming machines also play a crucial role in the overall manufacturing process. Trimming machines are used to cut and shape fasteners to ensure they meet specific lengths and specifications. The precision provided by trimming machines allows manufacturers to maintain strict quality control over their products.

Choosing the Right Trimming Machine Manufacturer

When selecting a trimming machine manufacturer, it is essential to consider several factors, including:

Experience: A manufacturer with years of experience in the industry will have a proven track record of quality and reliability.

Technology: The latest technology can improve efficiency and reduce waste, making it a crucial factor in selecting a supplier.

Customization: Different operators may have distinctive needs; therefore, a manufacturer that offers customizable trimming solutions can better serve your production requirements.

Support and Maintenance: After-sales support, including training and maintenance, is vital to ensuring uninterrupted operations.Thread Rolling Machine Supplier in India

Several manufacturers in India excel in providing trimming machines that complement the thread rolling process, helping to streamline fastener production.

Comments