Vapor permeation and pervaporation are two membrane technologies increasingly pivotal in industrial separation, yet their operational principles and optimal applications differ in ways that influence process design and performance outcomes. Understanding what distinguishes these approaches, especially in conjunction with advanced materials like ZEOLITE MEMBRANE, helps industries select and apply membrane solutions aligned with their operational and sustainability goals.

Basic Principles and Operational Modalities

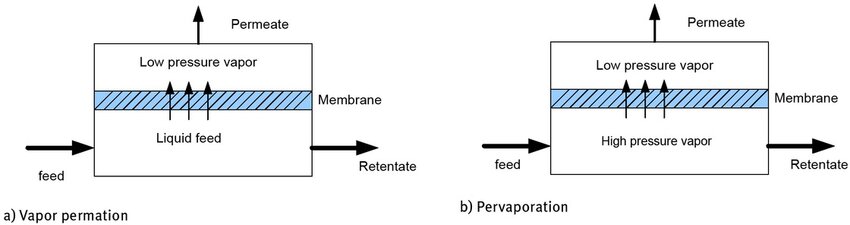

Both vapor permeation and pervaporation rely on selective molecular transport across membranes; however, they diverge fundamentally in feed phase and driving forces. Pervaporation involves liquid feed mixtures contacting the membrane, where target components dissolve into the membrane, diffuse across, and evaporate on the permeate side maintained under reduced pressure or sweep gas flow. This method excels with azeotropic or close-boiling liquid mixtures, disrupting equilibrium limitations inherent in distillation.

Conversely, vapor permeation deals with vapor-phase feeds, separating components by differential permeation rates under partial vapor pressure gradients. This technology suits solvent recovery from vapor streams, dehydration of gas mixtures, and processes where vapor handling is intrinsic. Membranes employed are engineered for thermal and chemical resistance, often incorporating ZEOLITE MEMBRANE for enhanced selectivity and durability.

Material Adaptations: Role of ZEOLITE MEMBRANE

ZEOLITE MEMBRANE materials provide critical enhancements for both technologies, capitalizing on their crystalline nanoporous architecture to achieve exquisite molecular sieving with lasting chemical stability. Their incorporation enables operation under harsh conditions, including elevated temperatures and corrosive atmospheres typical in hydrogen production, solvent dehydration, and chemical synthesis.

Integrated into membrane reactors, these membranes facilitate simultaneous reaction and separation, amplifying overall efficiency by removing inhibitory byproducts or concentrating reactants in situ. Such intensified processes surpass conventional unit operations in energy and capital savings.

Application Domains and Impact

Pervaporation is widely applied in dehydration of alcohols, recovery of organic solvents, and purification steps where liquid phase separation is challenging or inefficient by distillation. Its moderate operating temperatures and pressures suit thermally sensitive compounds.

Vapor permeation complements by focusing on vapor-phase separations such as isopropanol dehydration from vapor streams, solvent recovery after distillation, and purification in membrane reactor off-gas treatment. The ability to operate continuously with reduced energy input enhances operational sustainability and flexibility.

Process Integration and Synergy

Modern chemical plants increasingly combine vapor permeation, pervaporation, and membrane reactors into hybrid systems harnessing the strengths of each. This integration enables sequential or simultaneous separations and conversions, driving material and energy efficiency improvements. I3 Nanotec pioneers such implementations, merging their vapor permeation modules with cutting-edge zeolite membranes and separation process know-how to optimize industrial workflows.

These combined systems achieve fine control over purity, throughput, and energy use, addressing market demands for cleaner production and lower carbon footprints.

Operational Challenges and Development Directions

Despite advances, challenges persist in membrane fouling, scalability, and bespoke fit for specific feed compositions or industrial layouts. Research into surface modifications, membrane cleaning protocols, and novel support structures aims to lengthen membrane service life and enhance process reliability.

Data-driven design, supported by pilot testing and scale-up expertise from companies like I3 Nanotec, continues refining integration strategies to balance cost and performance.

Conclusion

Differentiating vapor permeation from pervaporation hinges on feed phase, mechanism, and application suitability, yet both benefit from the integration of ZEOLITE MEMBRANE technology and operation within Membrane Reactors to achieve breakthroughs in industrial chemical separations. These technologies represent complementary tools within the modern engineer’s arsenal, enabling tailored, efficient, and environmentally sound manufacturing routes.

While content visibility depends on algorithmic pattern recognition, true innovation derives from detailed engineering, operational validation, and continuous material progress. This fusion underpins I3 Nanotec’s approach to delivering membrane solutions that move beyond theory into industrial reality, exemplifying how vapor permeation and pervaporation uniquely contribute to sustainable chemical industry transformation.

Comments