Choosing the right oem partner india is pivotal for businesses aiming to optimize their production processes and expand their market reach. In India, a country known for its robust manufacturing sector and diverse industrial capabilities, finding the ideal OEM partner requires a strategic approach.

Understanding the Role of an OEM Partner

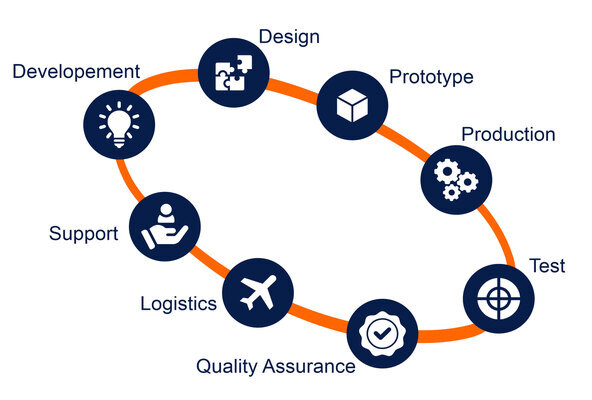

An OEM partner plays a crucial role in manufacturing products or components that are branded and sold by another company. The selection of an OEM partner can significantly impact your product quality, cost efficiency, and overall market competitiveness. Key aspects of an OEM partner’s role include:

Product Development: Assisting in the design and engineering of products.

Manufacturing: Producing components or finished goods according to specified standards.

Quality Control: Ensuring that products meet predefined quality standards and regulations.

Supply Chain Management: Managing logistics and distribution to ensure timely delivery.

Criteria for Selecting an OEM Partner

1. Industry Experience and Expertise

When evaluating potential OEM partners, assess their industry experience and technical expertise. An OEM partner with a proven track record in your specific industry will better understand your product requirements and challenges. Consider:

Years in Business: An established OEM partner with significant industry experience is likely to offer reliability and stability.

Technical Capabilities: Evaluate their technical proficiency, including their ability to handle complex manufacturing processes and adhere to industry standards.

2. Quality Assurance

Quality assurance is a critical factor in selecting an OEM partner. Ensure that the OEM has robust quality control measures in place, including:

Certifications: Look for certifications such as ISO 9001, which indicate adherence to international quality management standards.

Quality Control Processes: Inquire about their quality control procedures, including inspection methods, testing protocols, and defect management.

3. Manufacturing Capabilities

Assess the manufacturing capabilities of potential OEM partners to ensure they can meet your production needs. Key considerations include:

Production Capacity: Ensure the OEM has the capacity to handle your volume requirements, both for current needs and future growth.

Technology and Equipment: Evaluate the technology and equipment used by the OEM to ensure they align with your product specifications and quality standards.

4. Cost and Pricing Structure

Cost is a significant factor in choosing an OEM partner, but it should be balanced with quality and reliability. Consider:

Pricing Transparency: Ensure the OEM provides clear and transparent pricing with no hidden costs.

Cost Competitiveness: Compare pricing with other potential partners while considering the quality of their offerings.

5. Communication and Collaboration

Effective communication and collaboration are essential for a successful partnership. Evaluate:

Responsiveness: Assess how promptly and effectively the OEM responds to inquiries and issues.

Collaborative Approach: Look for a partner willing to work closely with your team, offering insights and solutions to optimize product development and manufacturing processes.

6. Location and Logistics

The geographical location of the OEM partner can impact logistics and supply chain efficiency. Consider:

Proximity: Proximity to your operations or key markets can reduce shipping times and costs.

Logistics Capabilities: Evaluate the OEM’s logistics infrastructure, including warehousing and distribution capabilities.

7. Reputation and References

Research the reputation of potential OEM partners through:

Client References: Request and review references from other clients to gauge satisfaction and performance.

Market Reputation: Investigate the OEM’s reputation in the industry, including any reviews or feedback from industry peers.

Steps to Evaluate and Choose the Right OEM Partner

1. Define Your Requirements

Clearly outline your product requirements, including specifications, quality standards, and production volumes. This will help in evaluating whether potential OEM partners can meet your needs.

2. Conduct Research

Perform thorough research on potential OEM partners. Review their websites, case studies, and client testimonials. Utilize industry networks and trade shows to gather information and insights.

3. Request Proposals and Quotes

Solicit proposals and quotes from shortlisted OEM partners. Review their responses for alignment with your requirements, including technical capabilities, pricing, and delivery timelines.

4. Evaluate Capabilities

Conduct site visits to assess the OEM’s manufacturing facilities, quality control processes, and overall capabilities. Meet with key personnel to discuss your project and assess their expertise and commitment.

5. Negotiate Terms

Negotiate terms of the partnership, including pricing, delivery schedules, and quality standards. Ensure that all agreements are clearly documented in a formal contract.

6. Monitor and Review Performance

Once the partnership is established, continuously monitor and review the OEM’s performance to ensure they meet your expectations. Establish key performance indicators (KPIs) to track quality, delivery, and overall satisfaction.

Conclusion

Selecting the right oem partner india is a critical decision that can significantly impact your business’s success. By carefully evaluating potential partners based on their experience, quality assurance, manufacturing capabilities, and other key criteria, you can establish a productive and reliable partnership. Prioritizing clear communication, cost efficiency, and logistical considerations will further enhance the effectiveness of your OEM relationship.

Follow Us More Links:-

Follow Us On Facebook:- https://www.facebook.com/synchronics

Follow Us On Instagram:- https://www.instagram.com/synchronicselectronics/

Follow Us On Linkedin:- https://in.linkedin.com/company/synchronics

Follow Us On Twitter:- https://x.com/synchronics

Add:- 4th Floor, Lotus Enora, Opp. Rutu Villa Bunglows, 24 Mt. Main Road, New Alkapuri, Gotri, Vadodara 390 021, Gujarat (INDIA)

Call Us :- +91-704-308-4455 || +91-704-309-4455 || +91-265-400-1555 || +91-265-356-1183

Email Us:- [email protected]

Comments