In the packaging industry, ensuring the strength and durability of corrugated boxes and other shipping containers is crucial. This is where box compression testing comes into play. Box compression testers are specialised instruments used to measure the maximum weight or force a package can withstand before deforming or collapsing.

What is a Box Compression Tester?

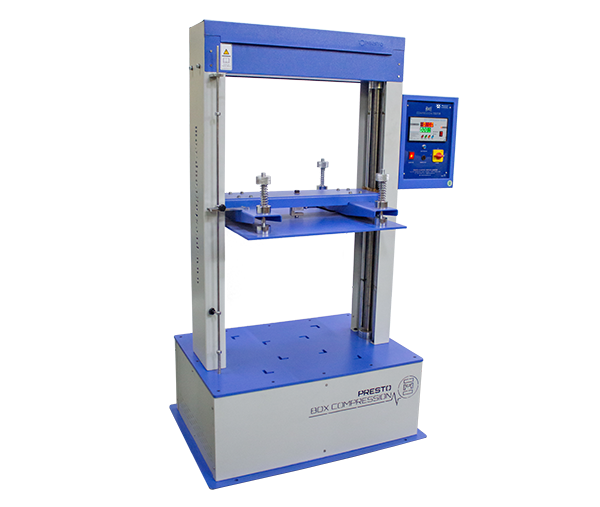

A box compression tester is a piece of equipment that applies controlled compressive force to a packaging sample. These tests are typically conducted on a universal testing machine, where the sample is placed between two flat platens or specialised fixtures. The tester then slowly applies an increasing amount of pressure to the package until it reaches its maximum compression strength.

Calculating Box Compression Strength

The box compression strength is calculated using the formula: BCT = 5.876 x ECT x √(P x T).

Where:

BCT is the Box Crush Test result

ECT is the Edge Crush Test result

P is the box perimeter

T is the box material thickness

This formula helps packaging engineers determine the optimal design and materials for their corrugated boxes to ensure they can withstand the rigours of shipping and handling.

The Importance of Compression Testing

Compression testing is a fundamental way to characterise a material's behaviour under compressive loads. By subjecting packaging samples to these controlled crush tests, manufacturers can:

- Evaluate the structural integrity of their packaging designs

- Ensure packages can safely transport and protect their contents

- Optimise material usage and minimise packaging costs

- Comply with industry standards and regulations

- Leading Manufacturers of Box Compression Testers

Companies like Presto Group are recognized as top box compression tester manufacturers, especially in the Indian market. Their testers are designed to be user-friendly and provide accurate, repeatable results to support packaging R&D and quality control.

In conclusion, box compression testing plays a critical role in the packaging industry, allowing manufacturers to validate the strength and durability of their products before they reach the supply chain. By understanding the principles and calculations behind these tests, packaging engineers can make informed decisions to protect their goods and meet customer expectations.

Comments